Austro Engine researches future propulsion systems for general aviation

A sister company to composite airframer manufacturer Diamond Aircraft, Austro Engine collaboratively studies an ignition jet option using sustainable aviation fuels for reduced emission results.

Representatives of the Vienna University of Technology, Austro Engine and Bosch General Aviation Technology in front of the test bench of the university. Photo Credit: Austro Engine/Diamond Aircraft

Austro Engine GmbH, a sister company of Diamond Aircraft Industries GmbH (Wiener Neustadt, Austria), which is well-known for its composites use in general aviation, has launched a program, supported by Bosch General Aviation Technology GmbH (Wien, Austria), to develop a bivalent hydrogen engine. The research project, in cooperation with the Vienna University of Technology as well as the Austrian Research Promotion Agency (FFG) — owned by the Austrian Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology (BMK) and the Federal Ministry for Digital and Economic Affairs (BMDW) — is scheduled for completion by the end of 2024.

“In renowned studies, hydrogen is regarded as the energy storage medium of the future. Undoubtedly, many challenges in the production and especially handling as well as infrastructure are not yet clarified. True to the motto ‘If you don’t go forward you go backwards,’ Austro Engine is taking responsibility for the next generation of propulsion systems for general aviation,” Felix Zahradnik, chief technology officer, Austro Engine, says. “In addition to highest efficiency with lowest emissions, factors such as operating costs, safety and worldwide availability have been decisive in determining the strategy of future propulsion concepts. We see our long-term future not only with sustainable aviation fuels, but also believe that hydrogen direct combustion might be a good propulsion system for general aviation.”

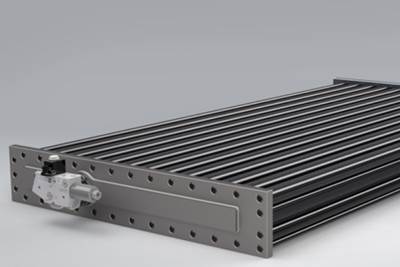

There are two different methods for the direct combustion of hydrogen in a piston engine. The initial ignition of the air/hydrogen mixture can be done either by a spark plug or an ignition jet. According to Austro Engine, the advantage of initiating the combustion by a spark plug is a constant, 100% hydrogen operation, which in an ideal case is regenerative.

However, if the ignition jet method is chosen, there are said to be clear advantages for general aviation. In the present case, the ignition jet is generated by the existing combustion process with kerosene. The substitution rate of kerosene by hydrogen can be adjusted for combustion stabilization but can also be modulated to 100% kerosene operation due to the current lack of availability of pure hydrogen in some regions of the world. The use of sustainable aviation fuels (SAFs) instead of conventional fossil kerosene for the ignition jet also meets the requirement of 100% substitution of fossil components and reportedly has no disadvantages compared to the spark plug-powered hydrogen engine in terms of sustainability.

Despite the early development stage of this project, considerable success has already been achieved. A 90% energy substitution rate at part load was achieved, which means a 99% reduction in CO emissions and 89% in CO2 emissions. In addition to the focus on reducing CO and CO2, the already low emissions of unburned hydrocarbons (HCs) at full load (maximum takeoff power) were also reduced by 25%. Besides basic research and combustion development, topics such as durability (hydrogen embrittlement) and European Union Aviation Safety Agency (EASA) certification are the focus of the further course of this project. All current research has been solely done on a test bench. Further information will be released after completion of the three-year program.

“Partnerships across industry borders are crucial to achieve sustainability in aviation. At Bosch Aviation Technology we are proud to be technology partner of Austro Engine and the Vienna University of Technology in public-funded projects, which integrate hydrogen in an existing engine line-up,” Christian Grim, general manager, Bosch General Aviation Technology GmbH, notes. “We are convinced that hydrogen will play a major role in regard to sustainable aviation solutions if used with fuel cells or in hydrogen engines. To face decarbonization as a major challenge for general aviation, it will become increasingly important to search for alternative propulsion systems.”

Diamond Aircraft and Austro Engine, together with Lufthansa Aviation Training (München-Flughafen, Germany), are also working on Sustainable Aviation Fuels options for the Austro Engine-powered aircraft line.

Learn more about hydrogen, “Hydrogen is poised to fuel composites growth, Part 1” and “...Part 2.”

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreRead Next

Hi-DEN project targets novel high-pressure hydrogen storage innovations

Carbon ThreeSixty, alongside partners Antich & Sons and Viritech, will manufacture, integrate and demonstrate a volumetrically efficient composite hydrogen system for land transport, short-haul aerospace.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More