Arrival EV producer becomes a Nasdaq-listed public company

Deliveries of composites-intensive EVs and expansion of global microfactory network set to ramp up, with first EVs due Q4 2021.

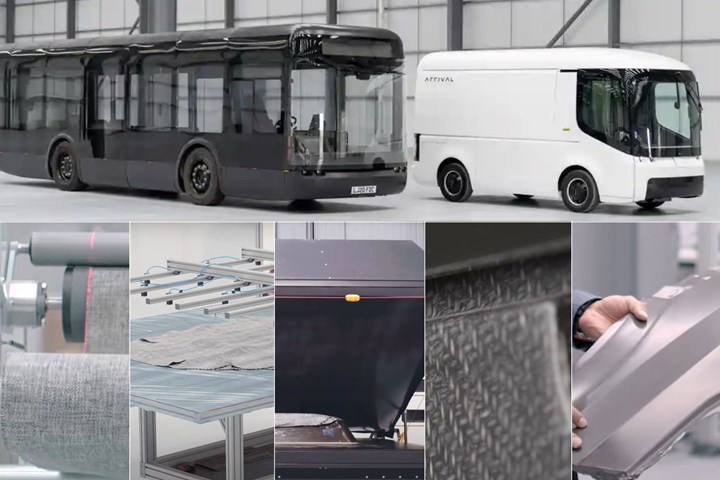

Photo credit: Arrival images compiled by CW

Global electric vehicle (EV) company Arrival (London, U.K.), became a publicly listed company March 25, trading on the Nasdaq Global Select Market with its Ordinary Shares and Warrants listed under the new ticker symbols “ARVL” and “ARVLW,” respectively. Arrival completed the previously announced special purpose acquisition company (SPAC) combination with CIIG Merger Corp. (New York, N.Y., U.S.) on March 24, 2021. The company plans to use its approximately $660 million in gross proceeds to ramp up delivery of its EVs and expand its global network of microfactories. Its first local facility in Rock Hill, S.C., U.S. is slated to begin producing the composite body panels for its EVs in Q4 2021.

“We believe that all vehicles will soon be electric, because it is better for people, the planet and business,” says Denis Sverdlov, founder and CEO of Arrival. “Arrival’s invention of a unique new method to design and produce vehicles using local microfactories makes it possible to build highly desirable yet affordable electric vehicles — designed for your city and made in your city. Going public is an opportunity that will allow us to continue to scale globally. We also understand that this comes with responsibility. Arrival has a remarkable company culture, which attracts great talent and enables us to be truly creative. The hard work of more than 1,800 people over the past six years has made this milestone possible, and I would like to personally thank each and every one of the team.”

Composite body panels

Due to the weight and cost of batteries and electric powertrains, explains Arrival chief of materials Rob Thompson, Arrival is using thermoplastic composites to make the body panels lighter and less expensive, in order to achieve cost parity with conventional diesel vehicles. The body panels start with fabrics which are laser cut, kitted and molded using automated manufacturing cells. This agile approach allows a smaller footprint in both space and cost versus traditional stamped steel bodies, which require billion dollar stamping, welding and paint lines. In contrast, Arrival uses in-mold coatings and its body panel tools cost tens of thousands instead of the millions of dollars required for stamped steel. Body panel waste can also be recycled and reused in new products.

New way to make vehicles

Arrival’s new method of designing and producing zero-emission vehicles is enabled by its in-house developed hardware, software and robotics technologies. This vertically-integrated approach uses low CapEx microfactories and enables Arrival to price its vehicles competitively with fossil fuel equivalents and provide customers with a lower Total Cost of Ownership (TCO). Arrival believes that by creating the best products and removing the price premiums that currently exist for EVs, it will help to accelerate the transition to clean-air and sustainable commercial vehicles.

Arrival’s microfactories are rapidly scalable and enable decentralized production that can be deployed in local communities, hiring local talent, paying local taxes and using the local supply chain. This hyper-local strategy also allows the production of vehicles designed for the local region’s mobility requirements, the company says.

Progess toward mass production

There has already been strong interest in its vehicles, says Arrival, with a commitment from United Parcel Service (UPS) to purchase up to 10,000 EVs plus an option for an additional 10,000.

Arrival’s Van is expected to begin public road trials with customers in summer 2021, and the Bus is expected to start trials in Q4 2021 with First Bus (Aberdeen, U.K.), reportedly one of the U.K.’s largest transport operators and leaders in sustainable mobility. Production for the Arrival Bus is expected to begin in Q4 2021 and the Arrival Van in the second half of 2022.

Arrival has grown to more than 1,800 employees located across the world including offices and engineering facilities in the U.S., U.K. and Germany. The company moved into its Bicester, U.K. factory last May, will open its North American headquarters later this year in Charlotte, North Carolina, and has also a new microfactory in Charlotte to fulfill the UPS vehicle order.

Arrival also recently announced its global Board of Directors, bringing diverse expertise with backgrounds at Marvel, Hyundai Motor Co., Hearst, Lyft and Netflix.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreTroubleshooting thermal design of composite battery enclosures

Materials, electrical insulation and certification are all important factors to consider when optimizing electric battery performance against potential thermal runaway.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)