AnalySwift and University of Central Florida work with NASA to develop thin-ply composites

Materials will be characterized and performance modeled for wide array of aircraft and space applications.

Analyswift (West Jordan, Utah, U.S.), a Purdue University-affiliated software company that provides efficient high-fidelity modeling software for composites, in conjunction with the University of Southern Florida as the primary research institution, has received a NASA Small Business Technology Transfer contract to improve the design of composites, including thin-ply composites, such as those needed for spacecraft and NASA missions.

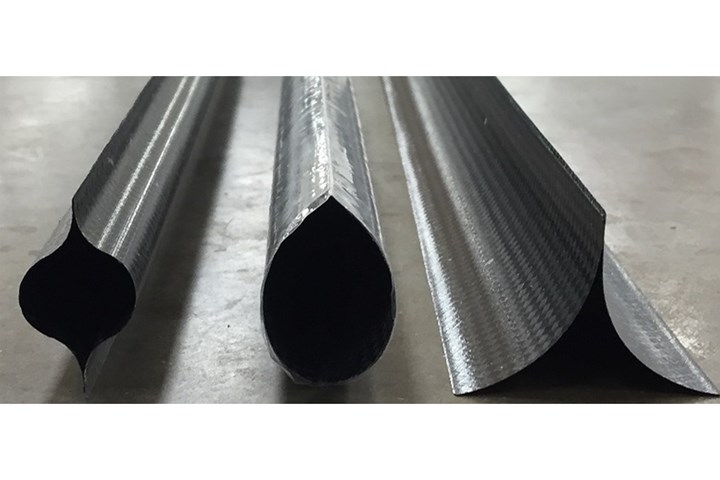

Thin-ply composites, named for their cured ply thicknesses of less than 0.0025 inch, are made from woven fibers materials such as carbon fiber, graphene and other polymers. Strength comes from slight curves along the ply’s edges that allow them to support weight rather than bending backward. This attribute reportedly makes them strong enough to support satellite payloads, such as solar sails for solar-powered space travel, or serve as supports for large spacecraft. Further, thin-ply composite structures can be rolled up, compacted and stored for long periods until need for deployment.

“Thin-ply composites offer significant gains in performance over traditional metallic materials for constructing deployable spacecraft structures,” says Kawai Kwok, an assistant professor in UCF’s Department of Mechanical and Aerospace Engineering who is leading the research. “The extreme thinness and the high failure strain limit of thin-ply composites results in folding curvatures that far exceed the current capability. They are both volume and mass efficient and can be manufactured at low cost with readily available materials and commercial processes.”

Kwok and his Structures and Materials Design Lab will use experimental and computational methodologies they’ve developed to characterize and model the performance of thin-ply composites and polymers designed for space environments under repeated use and long, compressed storage periods.

Kwok says the experimental data, theories and companion software developed from this research could be applied to booms, sails, panels, reflectors and more for satellites, as well as to lightweight structures for landers, rovers and solar arrays for NASA missions, and future aircraft with compact and vertical launching capabilities.

AnalySwift chose to work with UCF because of Kwok’s extensive experience with researching thin-ply composite materials, including for NASA, says Allan Wood, president and CEO of AnalySwift. “Professor Kawai Kwok has been collaborating with NASA on this problem, and AnalySwift is pleased to partner with UCF as the research institution on this project,” Wood says.

AnalySwift and UCF are also partnering with Purdue University (West Lafayette, Ind., U.S.), which will lead research code development, as well as run simulations needed for model verification and validation under the direction of Wenbin Yu, a professor in Purdue’s School of Aeronautics and Astronautics.

“There are currently no validated and reliable characterization and modeling methods and tools for this type of work that considers such extreme conditions and past loading histories,” Yu says. “Without reliable prediction and characterization capabilities, additional tests are often needed to circumvent any uncertainties in performance of the final design, consequently slowing down the technology development and delivery.”

For more information, contact Robert H. Wells, Office of Research,

robert.wells@ucf.edu

Related Content

-

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

-

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.