Spread tow brings new life to legacy markets

Spread tow and thin ply open new opportunities in composites for golf shafts/driveshafts, boats and spacecraft thanks to improvements in lead time, weight and performance.

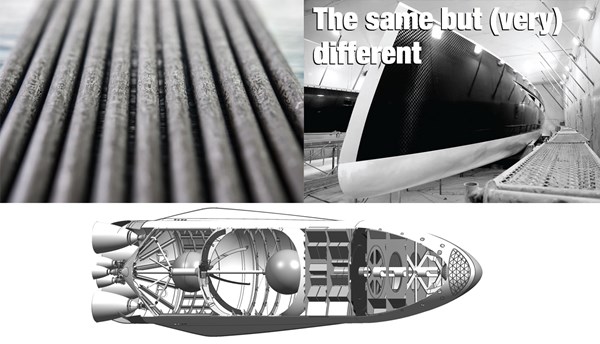

TOP LEFT: Carbon fiber composite tubes made using North Thin Ply Technology (NTPT) Thin Ply Prepregs. TOP RIGHT: Hudson Marine’s H66 catamarans use TeXtreme spread tow carbon fabric from Oxeon. BOTTOM: Current designs for the SpaceX Interplanetary Transport System (ITS) include a large carbon fiber composite fuel tank, which could benefit from liner-less tank technology being demonstrated with spread tow materials from Oxeon.

SOURCE: NTPT , Seahorse Magazine (July 2016 article) and SpaceX.

This sidebar to the June 2018 feature “The Spread of Spread Tow” gives more detail on developing applications for spread tow and thin ply materials in golf club shafts/driveshafts, boats and spacecraft tanks. These are all mature markets for composites where spread tow is opening new possibilities due to improvement in production time, weight, performance and/or damage tolerance.

Speeding marine sandwich panel production

Saving time not just in development, but in actual production is opening new markets for North Thin Ply Technology. “We have partnered with FIBRE Mechanics to meet a very tight boatbuilding deadline by automating construction of bulkheads and other panels,” Austin explains. “They received an order for 200 flat panels that needed to be delivered in 2-3 months and we were contracted to help make this happen.” NTPT works with FIBRE Mechanics to provide laminate kits which are then cured into panels.

“This first contract is for all of the internal structures for a 70-ft boat, which is quite a big structure,” says Austin. “Previously, we had done a 60m wing for the Solar Impulse 2 aircraft, but boats are very different from aircraft.” Yet, all of the work has proceeded apace, with additional upsides. “The weight of our prepreg laminates is significantly lower than the resin infused laminates used previously. Our cost was also lower, so with speed of delivery we provided an attractive solution.”

NTPT has received an order for boat #2 and there are 3 more boats to go, says Austin. “We are also working with another manufacturer to build all of the interior panels for a 40-ft motorboat.” He thinks NTPT can supply bent panels as well. Attaching bent sheet metal panels to metal frames is how metal boats 70-100m in length are built. “If we can make composite panels in a semi-automated way,” Austin posits, “we eliminate the mold, which not only saves cost, it dramatically shortens the build — fabricating a mold can take up to 9 months. There a quite a lot of owners who don’t want to wait three years for a boat.”

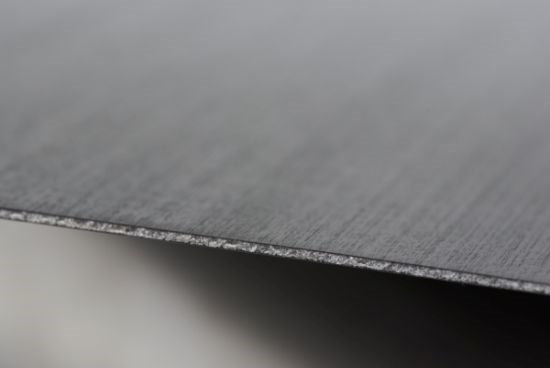

NTPT works with 4a manufacturing to produce sandwich panels less than 1.0mm inch thick.

SOURCE: NTPT.

Thin sandwich panels

NTPT has also developed very thin sandwich panels in partnership with 4a manufacturing. Austin says this technology was developed in 2017 using 4a’s thin core materials. “They achieve foam cores below 1.0 mm in thickness at high levels of accuracy,” he explains. The result is very lightweight sandwich constructions — e.g., 0.2-mm thick core and .002-mm thick skins. Austin notes applications to date include acoustic materials in lighting and speakers. 4a sees potential applications in automotive, marine, aircraft and drones, sporting goods and rail transport.

NTPT composite tubes made using Thin Ply Prepregs. SOURCE: NTPT.

Thin, discontinuous ply tubes for shafts

Another legacy market for composites being updated with thin ply and spread tow products is golf. NTPT’s development here is in discontinuous fiber tubes. The first idea was to exploit the homogeneity of thin plies. Austin explains, “If I have 6 layers of thin ply in a 300 g/m2 laminate, there is a discontinuity where I start and stop winding the fabric into the tube. But if I go to 30 layers, these discontinuities become insignificant. So we started winding tubes.” However, golf shafts are actually tapered. “As soon as you wind 180°, it won’t wind straight, so that the longitudinal fibers are no longer longitudinal,” he contends. “If we cut the thin plies into flags, however, the fibers do stay longitudinal. The act of making it discontinuous enables more accurate placement, and the resulting shaft plays more accurately vs. a normal shaft because the fibers are oriented more optimally.” Again, NTPT uses automation to make up for increased layers. “We use an in-house developed winding method vs. the current practice of converting continuous prepreg with either a table roller or hand rolling in China,” says Austin. NTPT is working with the Ecole Polytechnique Fédérale de Lausanne - SwissCentre of Technology (EPFL) to establish design rules for this new approach, such as how many discontinuous layers equal conventional, continuous fiber layers.

Austin says many new players are using the discontinuous tube construction for their golf shafts this year, which is springboarding this technology into new applications. What about driveshafts? “We think this may indeed be a good fit for thin ply,” he replies. “BMW has reverted away from CFRP shafts back to metal because of packaging space issues. They need to go thinner with the shafts, and CFRP shafts currently are thicker than metal.” According to Tsai’s work with thin-ply, bi-angle laminates, another advantage of spread-tow materials in this application is a 30% higher natural frequency, which is a key design driver for driveshafts. This boost should expand the driveshaft’s operating range in terms of vibration performance.

SpaceX unveiled this 40-ft carbon fiber composite tank in Sep. 2016 and reported that it passed a 2/3 burst pressure test two months later. SOURCE: BusinessInsider.com “The trickiest part of Elon Musk's Mars spaceship — a giant black orb — just passed a critical test”

Liner-less composite tanks – new spacecraft designs

Composites have been used in spacecraft for decades in body structures, deployable dishes, telescope structures and cyrogenic tanks. SpaceX showed off its 40-ft/12-m diameter tank last year and I blogged about the company’s previous issues with composite-wrapped aluminum tanks and how liner-less tanks could provide a solution (see “SpaceX announces COPV’s role …”):

SpaceX has announced conclusions from the accident investigation team as to the cause of the Sept. 1, 2016 explosion during fueling of a Falcon 9 launch vehicle in preparation for a launch at Cape Canaveral, Florida. … The team has concluded that one of the three composite overwrapped pressure vessels (COPVs) inside the second stage liquid oxygen (LOX) tank failed. These COPVs use the industry standard of carbon fiber composite wrapped over an aluminum liner, and are designed to hold super-cold helium (He) under high pressure. … Technologies for composite tanks without an aluminum liner were discussed by Sara Black in a 2005 CW article, and CW has written extensively about NASA’s composite cryotank.

Oxeon has supplied NASA and other spacecraft research programs with TeXtreme spread tow materials. Andreas Martsman, Oxeon VP of marketing and sales, discusses the effect that thin plies (<0.05mm) can have on space applications, especially cryogenic tanks. He notes that NASA and the European Space Agency as well as the Swedish Institute of Composites (Swerea SICOMP) have done studies showing up to 30% weight savings in applications like liner-less cryogenic tanks. “Weight savings of that proportion have not been seen in space since composites were first introduced,” says Martsman.

NASA is taking this development seriously, issuing an SBIR solicitation in January. In the CEAS Journal article, “The Aurora space launcher concept” by Alexander Kopp, et. al. (2017, CEAS Space Journal https://doi.org/10.1007/s12567-017-0184-2), work to date by NASA and Swerea are discussed in section 4.1 Thin‑ply CFRP technology overview and 4.2 Results of the CHATT project:

4.1

The conditions for the propagation of matrix cracks are much more favorable for the case of a UD composite than for a thin-ply in a multi-axial laminate. … Thicknesses < 100 μm commonly gives significant improvements by delaying the onset of matrix cracking. The fully developed crack in a thin-ply material is furthermore geometrically much smaller than for traditional roving laminae. …

A prime example for space applications is recent work by NASA where a 5.5-m-diameter cryogenic demonstrator test tank was developed in cooperation with the Boeing Company. This liner-less tank is using thin-plies for permeation barrier, ventable and purgeable sandwich structures, and structural health monitoring to support damage tolerance [17]. The tank passed a series of fill-and-drain tests, containing cryogenic liquid hydrogen with acceptable seepage. Weight savings over aluminum tanks approached the 35% target set by NASA. NASA describes extended thin-ply composites applications like this in their recent development called “Game changing development program, thin-ply composites for space exploration applications” [18]. According to this, thin-ply composites are those with cured ply thicknesses ranging from 64 to 25 μm or less.

4.2

Thin-ply materials have shown radical improvements in critical material properties during use in the recent EU project CHATT (Cryogenic Hypersonic Advanced Tank Technologies) [20, 21]. … The manufactured subscale demonstrator tubes have successfully been tested in CHATT toward the demanding loading conditions specified in the project, indicating that the TeXtreme material performs well as a load carrying liner material. The results from the testing showed that the selected winding angle of ± 25° for the plies effectively stopped the micro-cracks from growing through the thickness of the demonstrator. Hence, no leakage path was obtained through the laminate during testing although the axial tension load reached close to 1000 kN, corresponding to 1.6% applied axial strain, combined with – 150 °C and an inner pressure of 3 bar. Point-wise fractography evaluations after testing showed that the void content in the critical thin-ply layers is <0.5% while the void content in the roving plies is 3%, see Fig. 23. …

The introduction of thin-ply materials may thus enable new space vehicle designs.

NASA and CHATT liner-less cryogenic tank demonstrators using thin-ply materials.

SOURCE: “Enabling novel Space Transportation Vehicles by using Thin-Ply Composites” by Alexander Kopp, German Aerospace Center (DLR) and David Mattson, Swerea SICOMP, 27th Intl SICOMP Conference (May 2016, Linköping, Sweden)

Kurt Olaffson and David Mattson from Swerea have given multiple presentations on the CHATT program and on what they term “Thin-ply Micrometer Material Technology”. Their findings include:

- Thin-ply effect alters the stress state in the laminae. Minute cracks still initiate but can not propagate due to a needed larger crack propagation energy.

- The thin-ply effect can be viewed as a micrometer technology, transforming composites from a mm to a µm technology (regarding laminae thickness and fiber architecture).

At Oxeon, Martsman sees more opportunites for aerospace applications developing: “As the aerospace industry learns how to get the most out of thin plies and spread tow, applications will grow. In addition to reduced microcracking, these materials also help to achieve high productivity vs. conventional unidirectional tapes. It’s not perfect for all applications but it can grab applications in all of the traditional composites markets.”

And so we come full circle to increased productivity. “This is where the big potential in Spread Tow lies,” says Martsman. “Using cheaper, heavier tows, converting them more quickly than in any other way through weaving wide tapes — maybe 100mm wide — into a fiber architecture that has superior mechanical performance. This is why we have seen only the start of the ‘Spread of Spread Tow’.”

Related Content

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)