Overnight design allowables? An invariant-based method for accelerating aerospace certification testing

Dr. Stephen Tsai, professor research emeritus in the Department of Aeronautics & Astronautics at Stanford University, suggests a way to accelerate certification testing via “overnight design allowables.”

One of the problems with composite materials, as we all know, is the number of properties that must be measured and reported. At a minimum, each unidirectional ply has four stiffness properties: longitudinal and transverse Young’s moduli, plus one Poisson’s ratio and one in-plane shear modulus. In addition, it has five strength properties: longitudinal tensile and compressive strengths, transverse tensile and compressive strengths and in-plane shear strength. Then, when multidirectional laminates are made of unidirectional plies, the possible variations in stiffness and strength properties are limitless.

These static stiffness and strength properties of plies and laminates are currently also tested under different temperature and moisture combinations, such as room-temperature-dry, cold-dry, hot-dry and hot-wet. Strengths are measured for smooth, plain (unnotched) coupons as well as those with open or filled holes, and additional loading conditions of fatigue and compression-after-impact also are tested. Thus, the combination of tests easily totals 1,000 specimens, requiring months of testing and a huge budget.

This reality has limited the adoption of new materials and processes for composite structures, because allowables data are not promptly available. It is my purpose here, and in an upcoming workshop (described below), to put forth a different approach that will accelerate design allowables generation. It was developed with my co-investigators: José Daniel Diniz Melo, a consulting professor; Alan Nettles, a NASA (Huntsville Ala.) composite materials engineer and visiting scholar, both in the Department of Aeronautics & Astronautics at Stanford University (Palo Alto, Calif.); Dr. Waruna P. Seneviratne, technical director/scientist at the National Institute for Aviation Research (NIAR, Wichita, Kan.); Yasushi Miyano, professor of engineering at Kanazawa Institute of Technology in Japan (Ishikawa, Japan); and Jared Nelson, a doctoral research assistant from Montana State University (Bozeman, Mont.). We are proposing a radically new approach that will reduce the physical testing required for material evaluation, thereby accelerating the development of design allowables for new composite materials and processing.

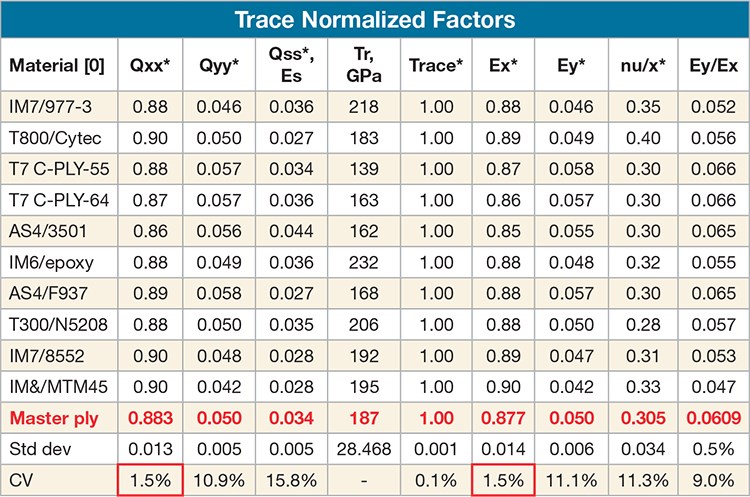

The first step in this process is recognition that trace of the stiffness matrix of an orthotropic material is invariant and embodies the entire stiffness relationship of the material. (Trace is the material factor derived from the mathematical matrix that is generated for a composite laminate, considering the four stiffness properties mentioned above, transformed to a single, all-inclusive property.) For the laminate stiffness, trace [A] = A11 + A22 + 2A66. In fact, working with NIAR, we found that for nearly 20 different carbon fiber/epoxy materials, the coefficient of variation (CV) for longitudinal stiffness is 1.5 percent (see the table below) — far smaller than the experimental variation.

We propose to use the median value of these normalized factors from many different materials and call it the master ply. We assert that the trace is the single value that can represent all the stiffness components of a composite material in both uni- and multidirectional laminates. Thus, if a given material can be represented by the master ply, only one test needs to be conducted for the determination of all stiffness parameters. This is similar to metals testing, where only one measurement is required — usually the Young’s modulus, assuming that Poisson’s ratio is 0.3, from which shear modulus can be calculated. For composites, it can be the same: If we know the value of trace (Tr), we can find all stiffness values just by multiplying the factors by the trace, i.e., longitudinal stiffness of unidirectional ply Ex* = 0.88Tr; for [0/90]E1° = 0.47Tr, and so on.

Now, we see that trace of a carbon/epoxy material is the one and only number that can define all laminate stiffness components: The first component, Qxx, is fiber-dominated and contributes to 88 percent of trace, while the other two, Qyy and Qss, are matrix-dominated and contribute only 12 percent. This may be obvious, but with trace we can define their contributions quantitatively. Trace is mathematically exact and precise, therefore, no additional assumption is required. Its value can be determined from one uniaxial test, avoiding the more difficult shear test.

Another benefit of trace is that laminated, rather than unidirectional, coupons can be used. Laminate coupons are closer to laminated structures and have the same uncertainties, such as processing defects. We further recommend the use of coupons with holes in place of smooth, plain ones, to represent manufacturing defects or damage from operation. Coupons with holes have less data variation, lower loads and allow for easier detection of defect and damage.

This approach also can simplify testing for environmental conditions, such as hot-wet. Work by a variety of researchers (e.g., Tay, Miyano, Nagada, Ha, Nettles and Rhead) has shown that stiffness changes due to environmental conditions can be regarded as small and can be approximated with an error range of 1 to 2 percent, and use of the time-temperature superposition principle is capable of simulating temperature and moisture environmental effects on mechanical properties. Shift factors have been developed to approximate these effects on stiffness and strength.

In conclusion, reliable design allowables can be very quickly generated with this proposed approach, reducing the number of test coupons required from more than 1,000 to fewer than 100, and testing costs from hundreds of thousands of dollars to less than $20,000. Tests actually conducted will be for validation of prediction, not data generation. One quasi-isotropic laminate sample can completely define not only the stiffness of all laminates, but also the failure stress and strain of open-hole tension and compression. Therefore, with this single panel, the entire design allowables set can be defined, and selected tests on critical loading conditions can be conducted in a matter of hours — ready for next-day delivery.

I hope that readers of this column will join me on site or online at the upcoming Composites Durability workshop, July 27-29 at Stanford University (here’s a link for more information: www.stanford.edu/group/composites/cdw19/) to learn more about this exciting approach and to see presentations of work that verifies its accuracy.

Related Content

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreFirst Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.

Read MoreMFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More