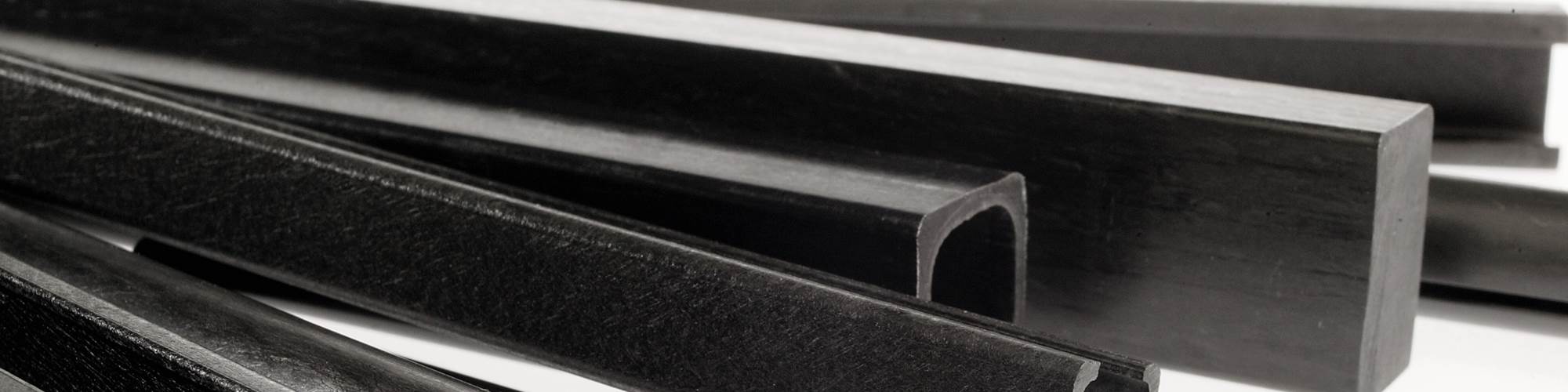

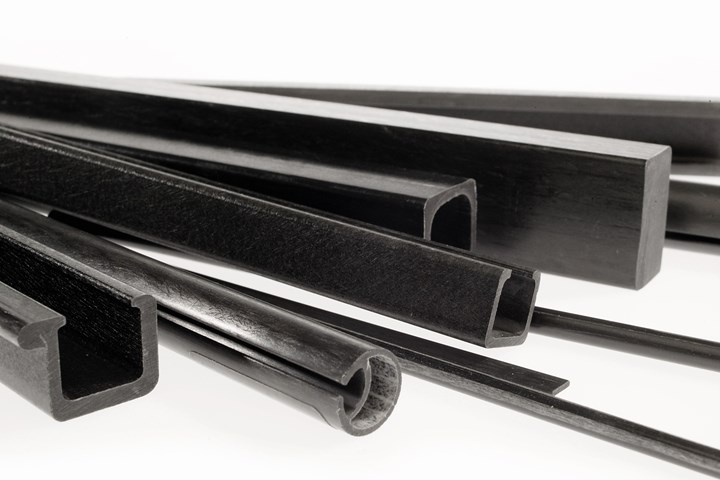

Unsaturated polyester resins can be adapted for the development of transportation, structural and construction profiles, as shown here. Photo Credit: Exel Composites

A composite material’s key components are fibers and a resin. The fibers, typically made of glass or carbon fiber, provide strength and stiffness, but if used alone, cannot be made into a shape or form where these properties are applicable. Impregnating the fibers with resin followed by curing, however, allows us to engineer their strength, stiffness and light weight for a variety of applications, while adding even more benefits to the composite.

As for the resin selection, there are many choices available, as well as the option to incorporate resin additives, to meet application requirements. Therefore, it’s very important to be aware of the differences between resins, and how their selection can affect a composite’s properties.

Complementing existing properties

All composites share common beneficial properties: strength, stiffness, light weight and resistance to harsh environments. Each of these features can be made more dominant by using a resin that complements them. To select the most appropriate resin, it’s first necessary to determine what its dominant feature should be.

A cost-effective way to make a weight-saving composite solution is to use an unsaturated polyester resin, which possesses relatively good mechanical, electrical and chemical properties. It can be adapted for a range of routine applications such as transportation, structural and construction profiles.

However, if an application requires a greater degree of stiffness or strength, then an epoxy resin is preferable. The bonding between an epoxy resin and the fiber is strong, which means higher shear loads can be transferred between fibers, giving the composite better strength values. Combined with the higher volume of fibers that the epoxy resin allows for, a composite with excellent strength and high stiffness can be made, which can be modified further to suit high-temperature applications if required.

Alternatively, if a composite requires resistance to harsh environments in addition to stiffness, vinyl ester resins may be a better choice. The molecular structure of vinyl ester facilitates chemical resistance, so if a composite is destined for a marine environment or an industrial application where acids or alkalis are present, using a vinyl ester will improve the composite’s performance.

When producing composite profiles that need to be assembled using screws, the composite needs to be robust to prevent cracks and breakage. This can be achieved through structural design, but selecting a suitable resin allows for a simplified structure and reduced costs, making the composite suitable for a wider range of applications. Polyurethane, for instance, is extremely tough in comparison to unsaturated polyester, making it ideal for such applications.

Adding new properties

Selecting a resin that will complement the most valuable features of a composite will enhance your composite’s performance and lifespan. However, improving existing properties is not the only advantage gained from taking the time to choose a suitable resin.

Resins can also add entirely new properties to a composite solution. Resin additives can be incorporated into the resin to achieve a range of benefits, from a simple improvement in surface finish or the addition of color, to more complex enhancements, such as UV resistance or antimicrobial and antiviral properties.

For example, since resins naturally decompose when left in sunlight, adding ultraviolet absorbers to resist UV radiation enables composites to achieve a better performance in light-intensive environments that would normally cause embrittlement and disintegration of the material.

Similarly, antimicrobial additives can be blended into a resin to prevent bacteria or fungi contamination. This is useful for any composite solution handled by humans, such as machinery, public transportation and medical devices.

Additive influence

It’s important to note that, in some cases, the inclusion of resin additives can alter the properties of a composite. In some cases, for example, fire retardant additives are needed in such high quantities to work efficiently that you must reduce the number of fibers in the composite, reducing its strength and stiffness.

Resin choice is a vital part of creating a composite solution and shouldn’t be overlooked. Establishing the most important function of a composite and designing the resin to improve the composite’s ability to perform this function allows us to create a composite solution in which the fibers and resin work harmoniously.

About the Author

Sami Pirinen

Sami Pirinen (PhD in materials chemistry) has been a chemist and technical support contact at Exel Composites since 2017. He has been working as a part of Exel’s R&D team to develop resin solutions to meet customer demands for composite products. He is also researching new resin materials to further expand the possibilities of composites to reach new applications.

Related Content

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreRead Next

Composites 4.0: Where to start?

Sensors, IoT platforms, data analytics — the tools for more intelligent, efficient manufacturing abound, but where to start is actually much simpler.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More