Digital fabrication aimed at sustainability

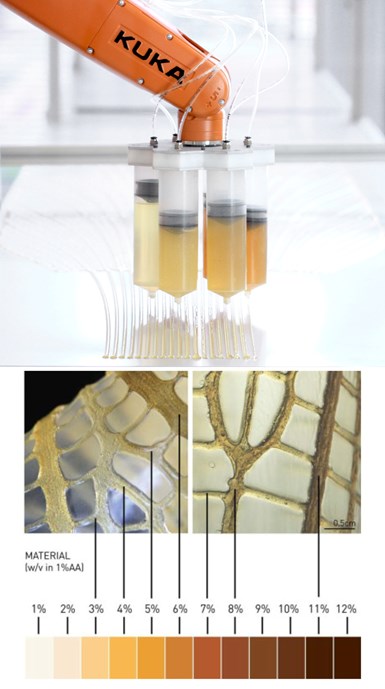

The Water-Based Digital Fabrication project at MIT developed and patented a novel system for using water-based solutions of bio-polymers like chitin and cellulose to create biocomposite structures that are lightweight and strong (top) with tailored gradients in chemical, mechanical and optical properties, including self-assembly during drying (lower right) and biodegradability at end of life. Photo credit, all photos: MIT Mediated Matter Group, MIT Media Lab

Nature builds structures that are amazingly strong, versatile and adaptive, growing and functioning in response to their environment — think of trees, bone and chitin. The latter forms both the hard shells and flexible joints of crustaceans. Nature’s constructions produce little to no waste, require very little energy and are recycled at the end of their functional lives. In contrast, man-made constructions are typically prescriptive, consume large amounts of energy, generate toxic waste and are mostly not recycled. According to 2018 data from the U.S. Environmental Protection Agency, the percentage of materials recycled is only 9% for plastics (no change since 2010), 25% for glass and 33% for metals (both down from 2010). Although digital design and fabrication are rapidly advancing and enabling production of sophisticated, multifunctional structures and components, these technologies have not yet made the same inroads in sustainability.

This was the inspiration and objective for the Water-Based Digital Fabrication project developed by the Mediated Matter Group at the Massachusetts Institute of Technology (MIT, Cambridge, Mass., U.S.) Media Lab, beginning in 2013. This initiative developed a novel digital manufacturing technology combining Earth’s most abundant natural materials with a robotically controlled, multi-chamber extrusion system that deposits varying concentrations of biocomposite solutions — the first was chitin from crustacean shells and acetic acid — to create structures with anisotropic properties. Gradients in mechanical, chemical and optical properties are produced across length scales from millimeters to meters, achieving not only unique geometries and multifunctionality, but also the potential for structural self-assembly. For example, the wet depositions can be designed to form shapes (e.g., cylinder) as they dry, in response to directional evaporation stresses within the multilayer composites.

This solution-based digital fabrication was envisioned as a bridge between the biological and built environments, with potential applications in sustainable architectural panels, recyclable packaging and consumer goods or lightweight biodegradable car parts. MIT eventually explored composites using cellulose microfibers, pectin, algae and ceramic nanoplatelets. But what if you could combine this water-based digital deposition with the continuous and short fiber-reinforced additive extrusion technologies rapidly advancing in today’s 3D printed composites?

Why chitosan solution?

Initial experiments in the Water-Based Digital Fabrication project used chitosan, derived from chitin. The second most abundant natural polymer on earth after cellulose, chitin has a similar chemical structure to cellulose and comprises not only the high-modulus, high-toughness shells of crustaceans and insects but also the strong yet flexible tissue found in their joints. Natural materials — especially polymers and polysaccharides like chitin and cellulose — provide a vast renewable resource produced at much higher rates than man-made synthetic polymers, explains Laia Mogas-Soldevila, one of the key MIT researchers in this project. She asserts that polysaccharide derivatives could replace existing petrochemical-based polymers, providing new property combinations and enabling more sustainable manufacturing.

Fig. 1. Creating organic structures

The MIT Media Lab developed a novel extrusion end effector for a KUKA robot using six cylinders to deposit gels made from chitosan powder at 1% to 12% concentrations in water-based solution. Biocomposite structures were produced, such as the example above, where stiffer, stronger veins were made using higher concentration gels, wider print paths and multiple layers onto which a clear, 2% concentration gel was bonded during deposition to create a tension-resistant membrane.

Mogas-Soldevila gives an excellent overview of the MIT technology development in her 2015 thesis, “Water-based digital design and fabrication: Material, product, and architectural explorations in printing chitosan and its composites.” She explains the idea to use solution-based digital fabrication came from studying inkjet and nozzle-based biofabrication methods to product soft materials as scaffolds for tissue growth.

It was decided to try nozzle-based 3D deposition using chitosan powder processed into a gel at weight-to-volume (w/v) concentrations of 1-12% using 4% w/v acetic acid in aqueous solution. These hydrogels ranged from a translucent liquid with viscosity like watery honey at 3% concentration, to an opaque material with the consistency of natural rubber at 12% concentration (Fig. 1). Initial results of deposited and dried chitosan films showed an ultimate tensile strength of 40 megapascals, which Mogas-Soldevila described as comparable to nylon polymer or wood in the direction of the fiber. Structures were fabricated and cured at room temperature.

Novel digital manufacturing platform

The custom robotic additive manufacturing platform that MIT designed to deposit the chitosan gels combined a KUKA (Augsburg, Germany) Agilus KR1100 six-axis robotic arm (a 54-kilogram platform with 10-kilogram payload and ±0.03-millimeter repeatability/accuracy) with an extrusion-based end effector. The novel end effector contained six barrels for the chitosan hydrogels connected to a computer-controlled air pressure system that included positive (compressed air tank) and negative (vacuum pump) air pressure with a digital PSI regulator and twin stepper motors to control extrusion.

This end effector weighed 4 kilograms including loaded syringes and deposition material. Typical flow rates ranged from 8-4,000 cubic millimeters per second using nozzles with an inner diameter spanning 0.5-8 millimeters. Linear motion of the system varied from 10-50 millimeters per second. Deposition area was 1,000 millimeters long by 500 millimeters wide, however, length limitations were later removed via a sliding print bed.

The stepper motors, pneumatic system and robotic arm were digitally controlled to coordinate feed/speed ratios, enable variable mixing ratios and extrusion rates and tune deposition pressure and speed on the fly based on the desired extrusion geometries and material properties. Robotic movement and extrusion were not explicitly linked — i.e., both functions were independent of each other —which allowed for independent control of each motor-driven syringe as well as the displacement of the robotic arm end effector. The system successfully produced large-scale 3D shapes without molds and achieved a wide range of geometrical forms with varying structural properties.

Digital design to deposition

Initial fabrication trials were based on biological structures like leaves and dragonfly wings. A principal longitudinal structure provided global shape, made with thicker diameter depositions and higher material concentrations for stiffness. Secondary structures were then formed by deposited networks of thinner-diameter and lower-concentration materials. The manufacturing system used several techniques to build these structures: applying different concentration solutions along certain paths, digitally controlling pressure during deposition to control material width and height and repeating layering. These strategies were encoded into the position, speed, pressure and material instructions that were sent in real-time to the KUKA robot (positioning) and extrusion end effector (deposition).

To begin, structures were modeled in a CAD program and then custom slicing software converted this into printed layers. The digital control system tested and optimized deposition paths. Geometric tool paths providing control and operation of the extrusion system were designed with Rhino3D modeling software (Robert McNeel and Associates, U.S.) and its scripting plugin Grasshopper.

The system then encoded an array of independent parameters associated with the digital design as well as basic mechanical and chemical material properties. It also moderated platform-dependent constraints given by the fabrication system such as viscosities, shear rates, barrel types, hardware response times and/or envelope size. All of these parameters were then combined with design-specific variations such as nozzle type, material composition and time-dependent pressure maps. Resulting calculations then output the necessary flow rates, barrel refill patterns and positioning speeds. Finally, custom fabrication instructions were generated, encoding motion and extrusion commands to the positioning and deposition systems, respectively.

Fig. 2. Aguahoja I pavilion

Held together by a 3D-printed thermoplastic spine, this 5-meter-tall pavilion demonstrated the use of biocomposite panels printed with the MIT water-based digital fabrication system. They were designed with varying degrees of stiffness, flexibility and opacity to create regions that serve as structure, window and environmental filter — all with the capability to be returned to nature at the end of their service life. (See video below)

Exploration of novel structures

Fabrication trials described by Mogas-Soldevila include a 50-centimeter-long structure inspired by dragonfly wings. Its structural “veins” were made from chitosan gel thickened with natural sodium alginate powder, onto which a clear tension-resistant membrane of 3% chitosan gel was overlaid. Due to the self-repairing characteristics of the materials, the membrane was bonded to the veins during deposition. This concept was further explored in a variety of leaf-like structures up to 3 meters long. In another example, a 5 x 15-millimeter grid was deposited flat using a solution of cellulose microfiber in 2% chitosan gel. As it dried, it formed a 50-centimeter-long cylinder, using the ability to design internal evaporation stresses as discussed above.

This technology was pioneered by Jorge Duro-Royo, architect and engineer and lead researcher at the MIT Mediated Matter Group under Prof. Neri Oxman, and further developed in the Aguahoja projects where skin-like structures (“hojas”) were created and shaped with water-based solutions ("agua"). Aquahoja I included a 5-meter-tall architectural pavilion (Fig. 2) and a library of material experiments that were exhibited in 2018 and then acquired by the San Francisco Museum of Modern Art (SFMOMA, Calif., U.S.) for its permanent collection. Aguahoja II was part of a 2019 exhibit co-organized by the Cube Design Museum (Kerkrade, Netherlands) and the Cooper Hewitt, Smithsonian Design Museum (New York, N.Y., U.S.).

The robotic fabrication platform in Aguahoja projects evolved to include both robotic- and gantry-based systems. The pavilion comprised 95 individual 3D-printed segments. The white spine was printed using an off-the-shelf F900 fused deposition modeling (FDM) system and acrylonitrile styrene acrylate (ASA) thermoplastic. The multiple biocomposite panels were designed with varying degrees of stiffness, flexibility and opacity to create regions that serve as structure, window and environmental filter. Some of the materials in Aguahoja I change in response to humidity and heat, others darken or lighten as the seasons change. The materials range from brittle and transparent to flexible and leatherlike, but all can be programmed to degrade in water (e.g., rain), thereby restoring the constituent building blocks to the natural ecosystem.

Mogas-Soldevila has since completed a doctorate at The Silklab within Tufts Biomedical Engineering (Medford, Mass., U.S.), looking at how to use silk and other natural fibers and materials, including those she worked with at MIT. She is now an assistant professor of Architecture at the University of Pennsylvania Stuart Weitzman School of Design where she teaches and researches material-driven design at the intersection of sustainability and cutting-edge life sciences. Some of her recent work can be found at dumolab.com. “These are materials that come from nature and are very easily functionizable — we can mix them, dope them and transform them. We can actually tune them to specific fabrication capabilities. We are looking at what’s next tomorrow.”

Fig. 3. Compostable packaging

Different compostable packaging concepts were explored using the biocomposite gels and digital fabrication systems developed at MIT.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)