New and newer at CAMX 2016

Airbus subsidiary for Industry 4.0 composites plus new products, processes and resources on display.

New Airbus subsidiary developing digital composites production for Industry 4.0

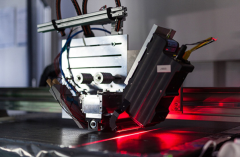

In an 8:30 am session on Sep. 29, Christian Weimer, head of Domain Composite Materials & Process for Airbus Group Innovations (Munich, Germany), spoke about “Increasing the Productivity of CFRP Production Processes”. Speaking mainly through the lens of increasing predictability and reliability, Weimer introduced where we are today and what is needed in order to make sure composites compete successfully on future airframes — one example: today, we have point measurements via laser scanning, but we need automated, inline 3D scanning.

He then announced that this summer Airbus spun off a new subsidiary, InFactory Solutions (Ottobrunn, Germany), that will develop, qualify and deliver sensor systems, data analytics and engineering consulting services for more automated, connected and intelligent manufacturing. Its first commercialization is a sensor that is applied directly to Airbus Group’s automated fiber placement (AFP) production for in-process quality monitoring of composite production that reduces inspection time by > 95%. The sensor can be used on any AFP head (e.g. AFPT, Coriolis, Electroimpact, Fives, Ingersoll, MTorres) and is qualified per Airbus Process Spec (AIPS).

Airbus’ Illescas, Spain plant is already testing the system for A350 XWB production, with German sites Airbus Group Helicopters in Donauworth and Premium Aerotec in Augsburg following by year-end. InFactory Solutions currently will offer its products & services to suppliers worldwide and aims to develop solutions for the complete composites process chain including other layup methods, cure, machining, etc.

Next generation of composite cure sensors — wireless temp. monitoring

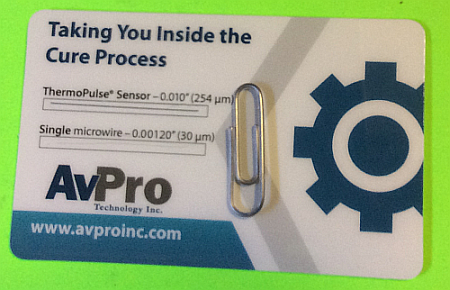

AvPro Inc. (Norman, OK, US) has partnered with TSI Technologies LLC (Wichita, KS, US) to develop the next generation of composite cure temperature sensors: The ThermoPulse system. Consisting of an antenna with transmit and receive capabilities, an embeddable microwire temperature sensor and a reader box, which collects the antenna readings, the ThermoPulse in-situ measurement system allows for wireless monitoring of temperature from the interior of a composite part or repair.

Measuring just 0.25mm by 32mm, ThermoPulse sensors are small enough to be permanently embedded within a composite interior or adhesive bondline in fly-away parts. Studies with American and European companies showed no significant difference in mechanical properties between samples created with sensors and those without.

Throughout the cure, the ThermoPulse Microwire supplies real-time temperature data to the controller, providing assurance and log records that performance-critical parts are actually reaching required temperatures. ThermoPulse can facilitate AvPro's Material State Management (MSM) solution for composites processing which helps provide critical visibility re: the degree of cure and the effects of a cure process on the part itself. (For more background, see “Automation and optimizing autoclave cure”.)

|

|

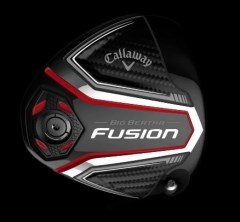

Triaxial Quantum Forged Preg lends new performance and aesthetics to golf club (left).

Carbon fiber SMC legs enabled Ferno’s engineered medical transport stretcher (right).

A. Schulman (now LyondellBasell) launched Quantum Forged Preg, a family of continuous carbon fiber-reinforced hybrid vinylester molding compounds, including triaxial, biaxial and unidirectional variants. Developed in collaboration with the world’s largest maker of premium performance golf goods, and the company’s fiber supplier, Quantum Forged Preg offers thinner parts vs. chopped fiber systems with exceptional strength and stiffness and is suitable for high-performance automotive and aerospace applications.

A. Schulman now offers a complete line of composite solutions, from thermosets to thermoplastics, having acquired Citadel Plastics Holdings Inc. (West Chicago, IL, US), which owned The Composites Group (TCG, Cleveland, OH, US), itself a rollup of Premix Inc., Hadlock Plastics and Quantum Composites. It will be establishing a new customer development center to shorten product cycles and provide material-agnostic development support. Stay tuned for more details.

|

|

|

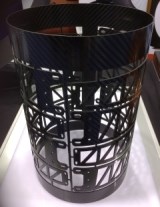

Rock West one-stop resource for composites

Rock West Composites (West Jordan, UT, US) stocks an amazing array of composites tubes — spread tow, natural fiber, filament wound, aramid, glass and carbon — and builds custom composite parts like Hans driver safety devices, suspension components, testing fixtures and industrial structures (e.g. armatures). It also offers a one-stop supply for fabrics, prepregs, cores, adhesives, composite plate and angle stock and myriad machining tools and process supplies.

Conductive composites for electrostatic painting

OCSiAl (Columbus, OH, US) exhibited its TUBALL single wall carbon nanotubes as a production-enhancing means for achieving conductive composite surfaces that must be electrostatically painted, for example, automotive exteriors.

|

|

More to come:

Adesso’s recyclable composites for circuit boards and buses, Ikonics precision abrasive machining and TEI Composites’ colored carbon fiber.

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)