Ensuring cure: Viscoelastic feedback

Material State Management measures the cure state of composite structures, enabling not only shorter cure cycles but also the ability to optimize cure cycles.

One of the goals of autoclaving a composite part is to convert the matrix resin from its liquid state (typically measured in terms of viscosity) to a solid state (typically measured in terms of modulus of elasticity). Historically, these changes have not been "visible"during the cure cycle. Manufacturers establish a process specification based on this change in viscoelastic properties over time and as temperature increases. The specification itself, however, typically states only time and temperature parameters. In the autoclave, the part is assumed to have reached viscoelastic goals (full cure), based on the secondary time/temperature indicators. During the actual cure cycle, however, lagging thermocouples, high thermal mass tooling and other issues can prevent some parts from reaching the viscoelastic threshold. In consequence, safety margins must be built into time/temperature calculations. How does a manufacturer ensure that the processed structures have fully cured, especially when those in question are not mere fairings, but fuselage sections for commercial aircraft?

In answer, AvPro (Norman, Okla.) has developed Material State Management (MSM), a viscoelastic feedback-based control system, adaptable to autoclaves or ovens, that is not dependent solely on time and temperature information. Instead, MSM measures cure state and then manages time and temperature parameters, using a simple rheometer to sense viscoelastic change in a 1.5-inch/38.1-mm diameter sample of the part's prepreg layup: The part is prepped conventionally for autoclave cure. Thermocouples are placed across the part and the part is vacuum-bagged. The sample is placed in a small, closed-cell mold capable of duplicating the autoclave's thermal cycle. Sample and part cure are initiated and, using AvPro-developed software, the MSM computer collects temperature data from the thermocouples on the part and sends the data to the rheometer/sample mold system. As the cycle progresses, the rheometer gauges viscosity change in the sample's matrix as it progresses from initial B-stage through flow, gel and vitrification, recording and analyzing data thoughout the process. The data is used to control and adjust - in near real time - temperature and time parameters in the autoclave or oven. It also can adjust vacuum and pressure and/or delay "hold"times to achieve, for example, desired compaction. Significantly, the cycle also can be ended as soon as the viscoelastic goal is achieved - no safety margins are necessary. If areas of the part have not reached goals, the control system ensures that the cure cycle continues until they do.

Although AvPro's software provides the above with standard thermocouples (that viscoelastic feedback requires dielectric sensors is a common misconception), greater capabilities are possible using multifunctional sensors. In addition, MSM stores time, temperature, viscoelastic and thermal data on all production process cycles. According to AvPro, the accumulated statistical history can be used to assess "out of specification"conditions that may have evolved during a previous run. It also can be used to establish a variety of specification limits, including infusion times for RTM. So why hasn't MSM already revolutionized the industry? "Many organizations are comfortable using legacy cures, and switching to MSM does require some investment,"explains Lou Dorworth, senior instructor at Abaris Training (Reno, Nev), who teaches MSM processing in Abaris' courses. Although MSM benefits from cure-control innovations developed by AvPro for the U.S. Air Force B1-B and B-2 bombers, NASA's Space Shuttle and The Boeing Co.'s (Chicago, Ill.) Delta Vlaunch vehicle, the resulting software was ahead of its time - the 286 processors and DOS code available to '80s users lacked the computing capacity to make the programs easy to use. Since then, hardware/software evolution has enabled an MSM application that today's PC users can easily run.

Related Content

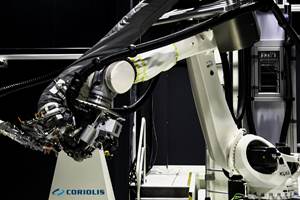

Coriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

Read MoreAutomated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

Read MoreWomen in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More