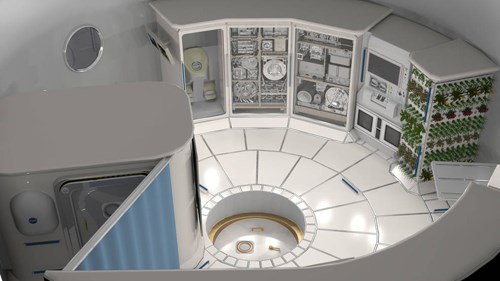

Living in space, surrounded by composites?

As humans travel further into space, the structures in which they live will become extremely important. NASA is working with six companies on development of deep space habitat designs that could represent a new end market for composites.

As humans venture deeper into space, habitation structures will be an important part of their living environment. NASA is working with six companies on development of deep space habitat designs.

It's not hard to imagine, when humans venture into deep space, that composites will be along for the ride in a variety of structures, ranging from space craft to the very structures in which humans will live. Along those lines, NASA has selected six U.S. companies to help advance the journey to Mars by developing ground prototypes and concepts for deep space habitats.

Through the public-private partnerships enabled by the Next Space Technologies for Exploration Partnerships-2 (NextSTEP-2) Broad Agency Announcement, NASA and industry partners will expand commercial development of space in low-Earth orbit while also improving deep space exploration capabilities to support more extensive human spaceflight missions.

The selected companies are:

- Bigelow Aerospace (Las Vegas, Nevada)

- Boeing (Pasadena, Texas)

- Lockheed Martin (Denver, Colorado)

- Orbital ATK (Dulles, Virginia)

- Sierra Nevada Corp.'s Space Systems (Louisville, Colorado)

- NanoRacks (Webster, Texas)

“NASA is on an ambitious expansion of human spaceflight, including the Journey to Mars, and we’re utilizing the innovation, skill and knowledge of both the government and private sectors,” says Jason Crusan, director of NASA’s Advanced Exploration Systems. “The next human exploration capabilities needed beyond the Space Launch System (SLS) rocket and Orion capsule are deep space, long-duration habitation and in-space propulsion. We are now adding focus and specifics on the deep space habitats where humans will live and work independently for months or years at a time, without cargo supply deliveries from Earth.”

The six partners will have up to approximately 24 months to develop ground prototypes and/or conduct concept studies for deep space habitats. The contract award amounts depend on contract negotiations, and NASA has estimated the combined total of all the awards, covering work in 2016 and 2017, will be approximately $65 million, with additional efforts and funding continuing into 2018. Selected partners are required to contribute at least 30% of the cost of the overall proposed effort.

The ground prototypes will be used for three primary purposes: Supporting integrated systems testing, human factors and operations testing, and to help define overall system functionality. These are important activities as they help define the design standards, common interfaces and requirements while reducing risks for the final flight systems that will come after this phase.

NASA made the first NextSTEP selections in 2015, which include deep space habitation concept studies that also advance low-Earth orbit commercial capabilities. Four companies were selected under that solicitation: Bigelow Aerospace LLC, Boeing, Lockheed Martin and Orbital ATK.

This round of NextSTEP selections are part of a phased approach that will catalyze commercial investment in low-Earth orbit and lead to an operational deep space habitation capability for missions in the area of space near the moon, which will serve as the proving ground for Mars during the 2020s. These missions will demonstrate human, robotic and spacecraft operations in a true deep space environment that’s still relatively close to Earth and validate technologies for the longer journey to Mars.

Video: This lunar habitat is made of glass-fiber-filled ABS and offers three important lessons for printing large parts. Watch here.

Related Content

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More