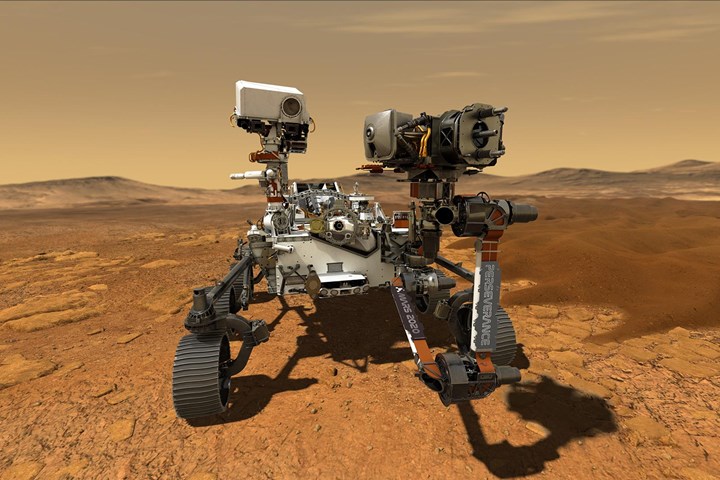

Structural landing deck panels on the Perseverance Mars rover were constructed from prepreg materials from Toray Advanced Composites. Source | NASA

From the launch vehicle to the landing parachute, rover to helicopter, composite materials and components play a significant role in NASA’s (Washington, D.C., U.S.) 2020 Mars mission.

On July 30, the Perseverance rover and Ingenuity Mars Helicopter took off toward the Red Planet atop an Atlas V rocket (United Launch Alliance, ULA, Centennial, Colo., U.S.), and is scheduled to land in Jezero Crater on Feb. 18, 2021. The Perseverance rover is equipped with various scientific instruments on board to study the astrobiology and geology of the Martian surface, looking for signs of microscopic life and preparing for future human missions through NASA’s Artemis program. The helicopter will stay tucked underneath the rover for about 60 days, NASA says, followed by about a month of controlled flight tests to gather data to inform the development of next-generation Mars helicopters. According to NASA, the rover’s technologies for entry, descent and landing will also provide information to advance future human missions to Mars.

The composites-intensive Ingenuity Mars Helicopter will be used for flight tests in preparation for future Mars missions. Source | NASA

“Perseverance is the most capable rover in history because it is standing on the shoulders of our pioneers Sojourner, Spirit, Opportunity and Curiosity,” says Michael Watkins, director of NASA's Jet Propulsion Laboratory (JPL, La Cañada Flintridge, Calif., U.S.). “In the same way, the descendants of Ingenuity and MOXIE [an on-board instrument designed to convert Martian carbon dioxide into oxygen] will become valuable tools for future explorers to the Red Planet and beyond.”

Spaceflight and landing

Like the Curiosity rover before it, which touched down on Mars in 2012, the aeroshell entry vehicle that serves as Perseverance’s launch vehicle and protection during its spaceflight and Mars landing features significant composites use. Toray Advanced Composites (Morgan Hill, Calif., U.S.) announced on Aug. 5 that its carbon fiber/cyanate ester prepreg was used for the structural support for the Mars entry heat shield, chosen due to its previous use on the Curiosity and Spirit rovers.

According to Toray, composite materials destined for space must meet rigorous requirements to ensure missions are successful, such as the ability to tolerate high temperatures, extreme light weight, low moisture absorption, high stiffness and low coefficient of thermal expansion (CTE) and off-gassing characteristics. For these reasons, Lockheed Martin (Bethesda, Md., U.S.), which developed and built the vehicle, chose Toray high-modulus cyanate ester prepreg for the structure to support the heat shield.

The Mars 2020 mission aeroshell entry vehicle features Toray carbon fiber/cyanate ester prepreg as structural support for the heat shield. Source | NASA

In Dec. 2019, Lockheed Martin announced that, alongside the shield used in the Curiosity mission, this is the largest aeroshell/heat shield ever built for a planetary mission, at 4.5 meters (nearly 15 feet) in diameter. In contrast, the aeroshell/heat shield of the InSight lander measured 8.6 feet; the Apollo capsule heat shields measured just less than 13 feet. Because of the large mass and unique entry trajectory profile that could create external temperatures up to 3,800°F (2,093°C), the heat shield of Perseverance uses a tiled phenolic impregnated carbon ablator (PICA) thermal protection system, according to Lockheed Martin.

“High service temperature composite materials provided by Toray Advanced Composites enable fabrication of extremely lightweight and dimensionally stable entry vehicle structures for planetary exploration,” says David Scholz, Mars 2020 aeroshell principal engineer for Lockheed Martin Space.

Para-aramid fibers add strength to the landing parachute’s suspension cords. Source | NASA

In addition, the landing parachute that will be deployed during the rover’s descent to Mars also incorporates composites, in the form of Teijin Aramid (Arnhem, Netherlands) Technora high-performance para-aramid fibers in the parachute’s suspension cords and parachute riser. According to Teijin Aramid, 60 kilograms (132 pounds) of Technora fibers are incorporated into the suspension cords, enabling the parachute, which was developed by Airborne Systems (Pennsauken, N.J., and Santa Ana, Calif., U.S.) and JPL to support a load of 31,751 kilograms (almost 70,000 pounds). Technora fibers were also used in the suspension cords of the Curiosity rover’s descent parachute.

“When designing and building the parachute system for Mars Perseverance rover, it was very important to utilize the volume that we were allocated to its fullest potential. Thanks to its outstanding strength-to-weight ratio, Technora allows us to do just that and increases the overall safety of the mission by providing more volume for stronger parachute cloth. There are many unknowns involved in any mission to space, but the tried and proven performance of Technora is not one of them,” says Charles Lowry, lead project engineer for Airborne Systems North America, Mars 2020 parachute system subcontractor.

“Our partners throughout the space industry have long recognized the unique potential of incorporating Technora into their products to unlock new levels of performance. The launch of the Mars Perseverance Rover shows that we’re again the partner of choice when strength and reliability are of unprecedented importance,” says Peter ter Horst, CEO Teijin Aramid.

Perseverance and Ingenuity

According to Toray, its prepreg materials were also used by JPL for the structural portions for the landing deck on Perseverance, and by AeroVironment (Simi Valley, Calif., U.S.) for the entire Ingenuity helicopter structure and highly specialized rotor blades. According to NASA, the helicopter's rotor blades are constructed from carbon fiber and foam core to provide lift in Mars’ relatively thin atmosphere, and the legs of the helicopter are made from carbon fiber composite tubes. The entire structure is reported to weigh 1.8 kilograms (4 pounds).

The Ingenuity helicopter chassis and rotor blades (pictured) are build completely from Toray composite materials. Source | NASA

“We feel our heritage in the space industry, as well as our ability to be collaborative on specialized projects such as the Mars 2020 mission, enforces our position as the ‘go-to’ composites partner for space applications,” says Steven Mead, managing director of Toray Advanced Composites. “Working with innovative companies such as JPL, AeroV, and Lockheed Martin to make space exploration continue is a privilege.”

According to Toray, previous rovers, Curiosity and Spirit, used unidirectional tape prepregs for the mast and submast components.

For more information on composites use in current and upcoming space applications, see “Composites in the race to space.”

Related Content

Carbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreExpanding high-temperature composites in India and the U.S.

Azista USA offers polymers and processes for carbon/carbon and other CMC, including novel hot-melt phenolic and phthalonitrile prepregs for faster cycle times, alternative solutions.

Read MoreCIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

Read MoreRead Next

Composites in the race to space

Advanced materials use in current and upcoming NASA missions.

Read MoreComposite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read MoreThermoplastic composite materials and processing interactions

Selection of product material formats and their interactions with various process methods heavily influence a final TPC part’s properties and fabrication options.

Read More

.jpg;width=70;height=70;mode=crop)