CAMX 2017 preview: PolyOne Advanced Composites

PolyOne Advanced Composites (Avon Lake, Ohio) is featuring its portfolio of continuous fiber thermoplastic and thermoset composite technologies.

PolyOne Corp. (Avon Lake, Ohio) is featuring in booth N88 its specialty portfolio of continuous fiber thermoplastic and thermoset composite technologies. In addition, PolyOne is processing its Polystrand thermoplastic composite materials in a forming demonstration and sample giveaway at the Composites One/Closed Mold Alliance booth K32 during the show.

Displays in the PolyOne booth focus on:

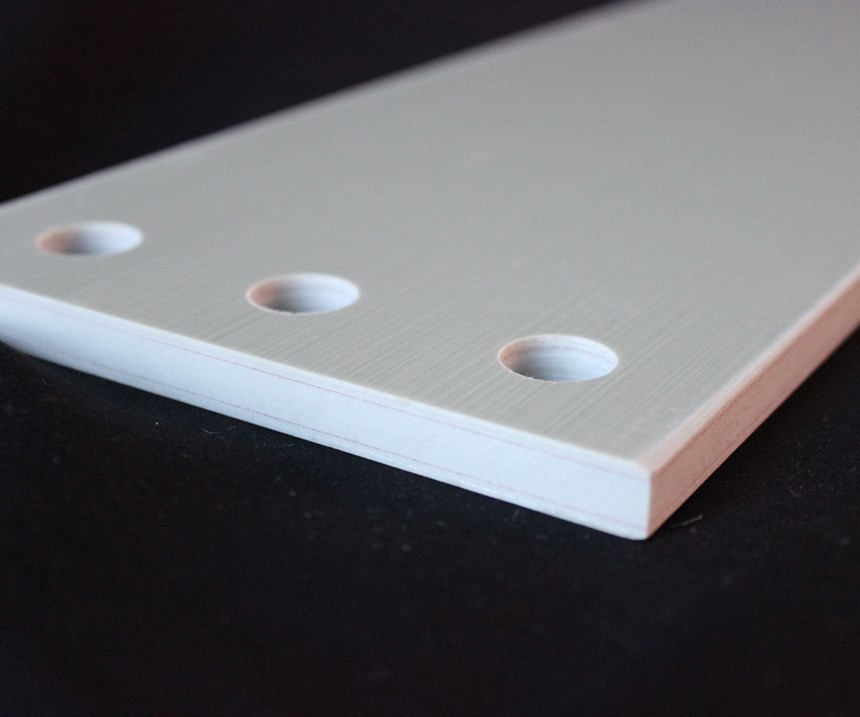

- Continuous-fiber thermoplastic composite sandwich panels. These high-fiber-volume, glass-reinforced structural panels offer high surface energy for bonding, painting and finishing and strong adhesive properties for thermal bonding to various materials

- Composite springs for furniture and industrial applications: Highly designed thermoset composite springs for seating, furniture and vibratory conveyance feature a high strength-to-weight ratio, long-term corrosion resistance and deep deflection for repeatable, efficient performance

- Pultruded thermoset composite components for a variety of applications. Featured products include nonconductive electrical insulator rods, utility poles and crossarms, carbon fiber automotive underbody chassis stiffeners, high-performance outdoor sporting good shafts and rods and ballistic-resistant panels

PolyOne’s Fayaz Ali, advanced composites engineer, will present two papers at CAMX. “Effect of Kaolin Clay as Filler on Mechanical Properties of Unidirectional Reinforced Pultruded Composites” is Wednesday, Sept. 13, 10:30-10:55 am, in W208B; “Unique Methodology for Testing Transverse Tensile Properties of Unidirectionally Reinforced Pultruded Composites” is Thursday, Sept. 14, 10:30-10:55 am, in W208C.

Yves J.M. Cordeau, chemist/engineer at PolyOne Glasforms, is presenting “Static and Dynamic Materials Analysis of a Carbon Fiber Epoxy Pultrusion System” on Tuesday, Sept. 12, 3:00-3:25 pm, in W209A.

Presented by Darcy A. Hornberger, market develpment manager, is presenting “Improving Performance, Material Consolidation and Manufacturing Efficiencies through Advancements in Pultrusion” on Wednesday, Sept. 13, 9:00-9:25 am, in W208B.

Related Content

-

JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

One-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

.jpg;maxWidth=300;quality=90)