Resin Transfer Molding (RTM)

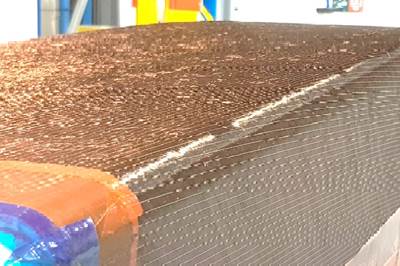

Resin Transfer Molding (RTM) is a popular manufacturing technique in composite production, involving the infusion of resin into dry fiber reinforcements within a closed mold. This process offers precise control over resin distribution, resulting in high-quality, void-free composite parts. RTM allows for the creation of complex shapes and intricate designs while maintaining consistent mechanical properties.

Latest RTM Articles

VIEW ALLFrom the CW Archives: The life and death of the BMW i3

A look back at the ambitious and impressive composites production system BMW developed for production of the all-electric i3 EV.

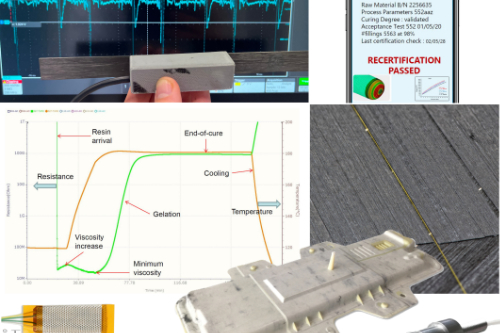

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

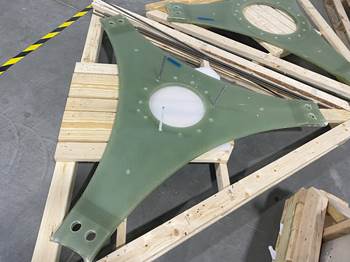

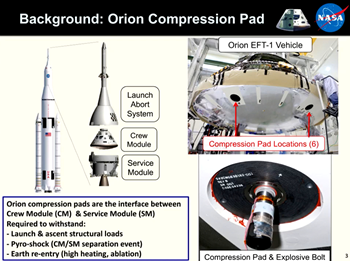

Read MoreBally Ribbons 3DMAT quartz composite is adopted for future NASA space missions

Named the NASA Government Invention of the Year, the 3D orthogonally woven materials supports structural and thermal performance needs for Orion mission and more.

Read MoreKnowledge Centers

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest RTM News And Updates

Live demonstrations present closed molding advancements

CAMX 2023: The Composites One and Closed Mold Alliance demo zone returns with short but engaging exhibitions featuring vacuum infusion, reusable bag molding, light RTM and other technologies through the show.

Read MoreReusable vacuum bagging, vacuum sealing solution

CAMX 2023: SWORL is highlighting its spray-fabricated reusable vacuum bags (membranes, foils) and a new sealing product for more sustainable, out-of-autoclave composites processing.

Read MoreFST-rated thermoset resin with rapid, tunable cure is designed for infusion

CAMX 2023: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

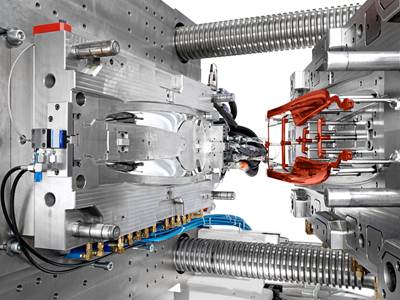

Read MoreMachinery, systems manufacturer highlights 3D printing, thermoplastics processing

CAMX 2023: KraussMaffei is featuring a variety of technologies, including Fiberform, ColorForm, RTM, extruder-based 3D printing and more.

Read MoreResin injection systems promote precise infusion control, automated resin handling

CAMX 2023: Radius Engineering is presenting its highly automated Multi+ 2K Injection Systems equipment well-suited to RTM, SQRTM and VARTM processes.

Read MoreHexcel launches novel RTM resin, rapid-cure prepreg for aerospace

HexPly M51 prepreg and HiFlow HF610F-2 resin add to Hexcel’s delivery of faster cure cycles and thus higher production build rates.

Read MoreFeatured Posts

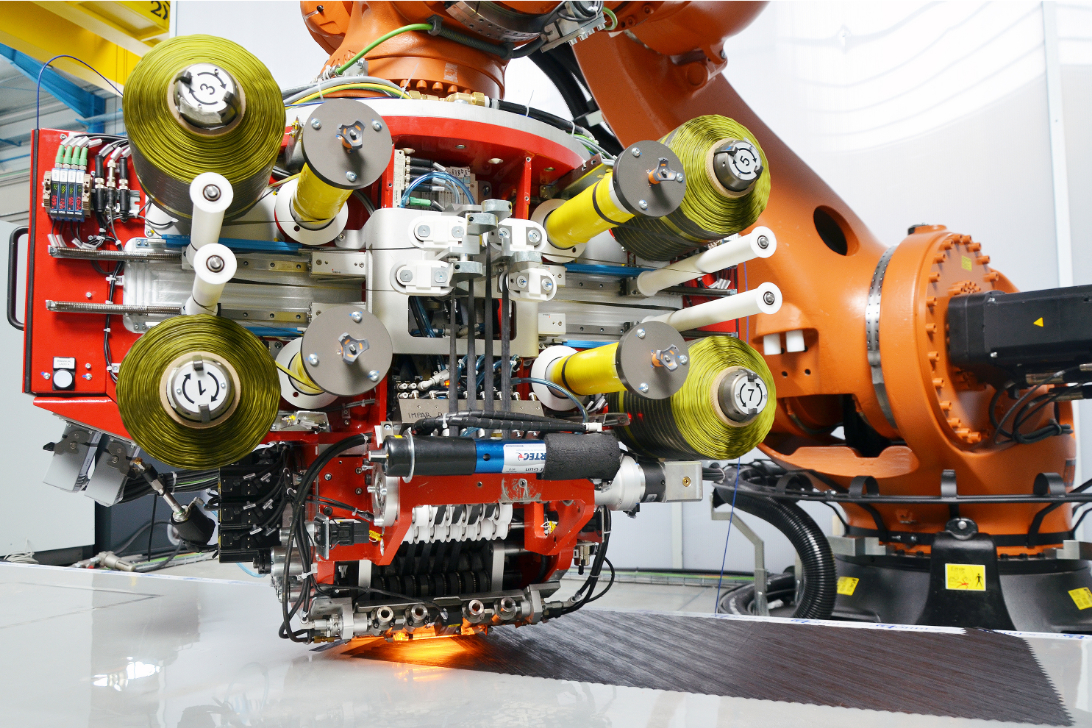

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

WatchPlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

WatchOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreDigital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

WatchFAQ: RTM

What is RTM?

Resin Transfer Molding (RTM) is a popular manufacturing technique in composite production, involving the infusion of resin into dry fiber reinforcements within a closed mold.

What does RTM stand for?

Resin Transfer Molding (RTM).

What is Light RTM?

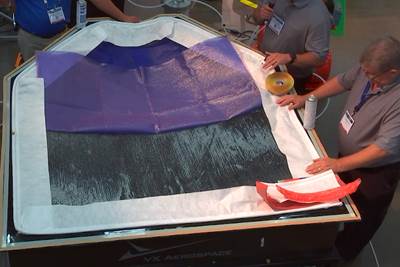

Light Resin Transfer Molding, or Light RTM, is a process by which composite products are manufactured using a closed mold system. The closed mold consists of an “A” side mold (base mold) and a semi-rigid “B” side mold (counter mold) that is sealed to the “A” side mold using vacuum pressure. Resin is drawn into the resulting cavity under vacuum.

The resin infusion may be assisted by a resin injection pump, which will accelerate the infusion process. Once an “A” side mold is cured, the “B” side mold is removed and the part is demolded from the “A” side mold.

Source: Light RTM

.jpg;maxWidth=300;quality=90)