Composites Processes

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Narrow Your Processes Search

Latest Processes Articles

VIEW ALLUMaine’s novel polymer 3D printer surpasses former Guinness World Record

Four times larger than its 2019 predecessor, Factory of the Future 1.0 offers new opportunities in composite materials, including development of recycled and bio-based materials, opening up new research frontiers.

Read MoreFrom the CW Archives: The life and death of the BMW i3

A look back at the ambitious and impressive composites production system BMW developed for production of the all-electric i3 EV.

Read MoreVoxelMatters report reveals top companies in composites AM

The new market study identifies key players in a $785 million global market that has grown by 21% year on year.

Read MoreBelotti, Cosberg partner for advanced automated assembly solutions

The Italy-based companies merge technological know-how to develop novel systems for the processing and assembly of light alloys and carbon fiber components.

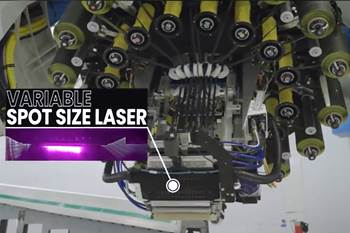

Read MoreElectroimpact offers variable spot size laser AFP 4.0 technology

Patented process technology increases quality, reliability and machine utilization for composite laminate production.

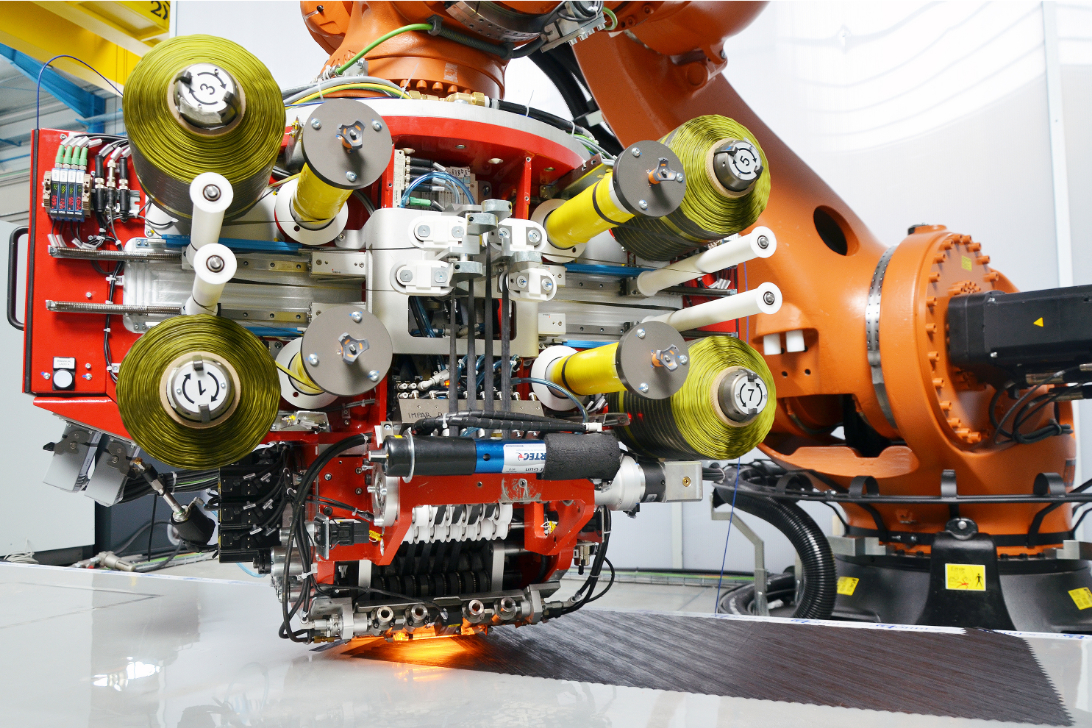

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchKnowledge Centers

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORE

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Processes News And Updates

ILAuNCH Trailblazer project to use AM technologies to produce large-scale composite rockets

ILAuNCH partnership, joined by ANU and New Frontier Technologies, will develop a qualified manufacturing process that will directly contribute to the development of launch vehicle development.

Read MoreMaterialise adds three materials to enhance industrial 3D printing

Materialise expands additive manufacturing portfolio with early adoption of new HP PA 12S and integration of PA 11 and PA-CF materials.

Read MoreFiber Dynamics invests in GX 1100 DCIM from KraussMaffei

Direct compounding injection molding (DCIM) enables the composites company to develop, test and protect its own recipe formulations, while increasing cycle times by eight times and reducing energy consumption.

Read MoreUMaine researchers aim to recycle wind turbine blades as 3D printing material

With a DOE grant in hand, UMaine’s ASCC seeks to develop an approach to recycle shredded wind turbine blade material as a cost-effective reinforcement and filler for large-scale 3D printing.

Read MoreExel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.

Read MoreAirtech, AES partner to grow LFAM applications

Airtech will provide extensive AM support, while AES commits to exclusive use of Airtech products, all of which will further materials development, market strategies and design practices.

Read MoreFeatured Posts

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

WatchAI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

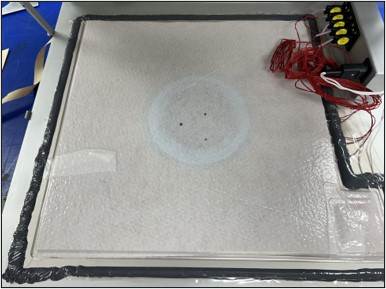

Read MoreRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

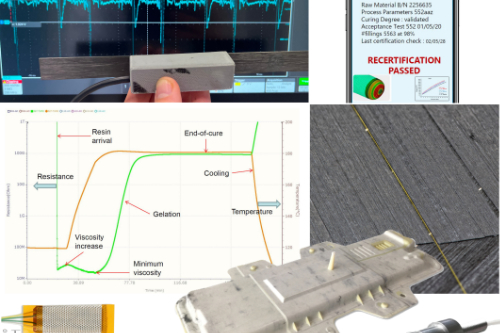

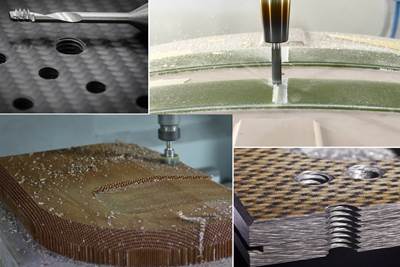

WatchOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

WatchFrom the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

Read More

.jpeg;maxWidth=400;quality=70)