Composites Use in Military & Defense

One of the main drivers of composites use in defense-related structures – such as components for fighter jets and other aircraft, weapons systems, and to some extent land- and water-based vehicles – is the high temperatures and harsh conditions in which these applications are used. Composite materials also offer high impact resistance, light weight and corrosion resistance needed for work in the field.

Latest Defense Articles

VIEW ALLZotefoams to provide cellular foams to personal protection expert Design Blue Ltd.

Zotefoams’ closed cell, crosslinked, nylon-based foam included in high-performance impact protection solutions for defense and law enforcement.

Read MoreConstruction begins on Boeing Australia MQ-28 production facility

The 9,000 square-meter Queensland facility will bring new aerospace skillsets and technologies, including composites manufacturing, robotics, testing and assembly capabilities.

Read MoreJanicki receives Northrop Grumman Supplier Excellence Award

Designer and builder of tools, parts, prototypes and assemblies earns recognition for supporting defense manufacturing and distribution goals.

Read MoreMARS Center grows LFAM capabilities with JuggerBot 3D Tradesman Series

P3-44 pellet-fed 3D printer is capable of leveraging a range of fiber-reinforced composite materials, to be used for the production of high-fidelity components in aerospace and defense.

Read MoreDefense manufacturer reflects on growth, opportunity in complex composite structures

Long Island-based, four-time CW Top Shops honoree GSE Dynamics cites diversification in processes, digitalization, workforce training and more on its successes over 50+ years, and looks ahead to future growth.

Read MoreToray celebrates commissioning of expanded Torayca T1100 production line

Doubled carbon fiber production capacity at Toray’s Decatur, Alabama, plant will support rising demand in U.S. defense.

Read MoreKnowledge Centers

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORE

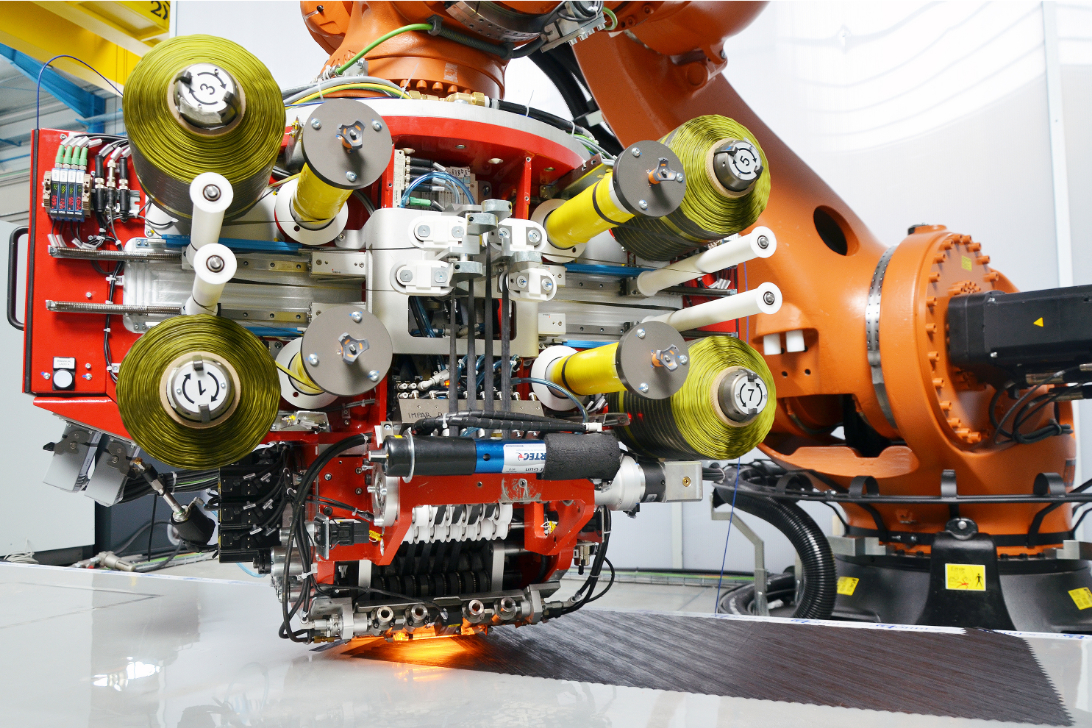

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORE

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORELatest Defense News And Updates

Beta Technologies completes first Alia deployment with U.S. DOD

The U.S. Air Force conducted on-base and cross-country mission and performance evaluations of Beta’s composites-intensive CTOL aircraft, hitting key milestones.

Read MoreAMD receives DASA funding for U.K. unmanned air system competition

AMD will incorporate existing low-cost radar absorbing material technologies to advance autonomous air systems.

Read MoreAirbus Helicopters expands UAS portfolio with Aerovel

The U.S. company brings with it the Flexrotor UAS aircraft, which will strengthen Airbus’ intelligence, surveillance and security capabilities.

Read MoreDzyne Technologies announces new California manufacturing facility for UAS production

Dzyne offers composite fabrication, avionics fabrication and assembly, and aircraft integration among other manufacturing capabilities to support current and future UAS needs, further enabled by the new 125,000-square-foot facility in Irvine.

Read MoreDOD awards $3.7 to Qarbon Aerospace to enhance thermoplastics production

Qarbon Aerospace will focus on the design, development and manufacture of a thermoplastic composite structure for defense aviation components requiring icing protection.

Read MoreIntegris Composites unveils customizable composite ballistic shields, vests

Rapid Don/Doff body armor vests and tailorable shield service enhances military and law enforcement unit options.

Read MoreFeatured Posts

Ballistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MorePlant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

WatchLockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read MoreFAQ: Defense

How are composites used in the defense market?

Composites can be used to lightweight defense aircraft and other vehicles, increasing range or allowing higher payloads.

Ultra-high temperature (UHT) composite materials can also be tailored to withstand harsh environments and high temperatures, or to be antiballistic. Research and production of ultra-high temperature (UHT) ceramic matrix composites (CMC), with melting points of 2,500°C (4,532°F) or higher, has ebbed and flowed over the years, following rising and falling demand for applications like hypersonic defense systems and space launch vehicles.

Source: Lockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Can composite materials be antiballistic?

New materials cntinue to be developed for use as bullet-proof armor for vehicles, infrastructure and equipment.

Historically, antiballistic material designers have preferred tough but expensive aramids, high-density polyethylenes and the like, passing over conventional E-glass as too brittle to have ballistic stopping power.

Proprietary additives and resin systems have enabled the development of bullet-proof fiberglass materials. 3D weaving of carbon fiber, fiberglass or other composite materials can also help to develop high-strength preforms for use as armor materials or molded panels.