Curing

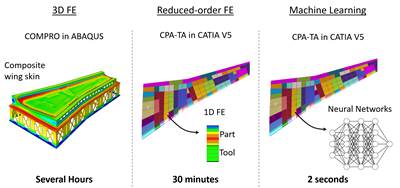

Using machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

Read MoreCAMX 2021 exhibit preview: Veelo Technologies

Veelo Technologies presents an education session at CAMX 2021 on out-of-autoclave, out-of-oven heating solutions.

Read MoreBriskHeat enhances silicone rubber blanket line

Composite curing heating blankets under the company’s SR Series are ultra-flexible, produce uniform heat up to 450ºF and are now compatible with any hot bonder plug.

Read MoreCAMX 2021 exhibit preview: LEWCO Inc.

LEWCO Inc. demonstrates its line of industrial ovens for the composites industry, including batch ovens, composite curing ovens, conveyor ovens, field assembled ovens and drum and tote heaters.

Read MoreHexcel sponsorship showcases carbon fiber prepreg capabilities for UAV applications

Students from the University of Applied Sciences Upper Austria developed a camera drone from Hexcel carbon fiber prepreg and resin systems for a 42% reduction in structural mass.

Read MoreUniversity of Bristol, NCC develop novel composite materials to assess performance in space

In-house developed matrices reinforced with carbon fiber will spend six months attached to the ISS to better understand and improve their functionality in extreme space conditions.

Read MoreLEWCO presents enhanced-duty, vacuum-assisted composite curing oven

The composite oven, recently delivered to a U.S. military base, reaches a maximum temperature of 500°F and is used to cure vacuum-bagged composite aircraft parts.

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

Read MoreEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

Listen

.jpg;maxWidth=300;quality=90)