Design & Tooling

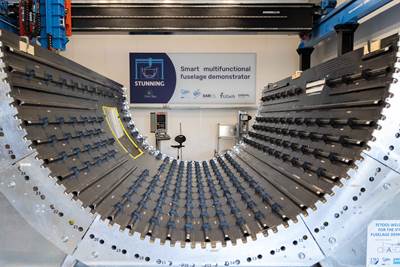

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Read MoreVertical Aerospace conducts successful airborne flight test

British aerospace company celebrates “wheels up” for the first time in a new intensive test program phase, following its CAA permit to fly.

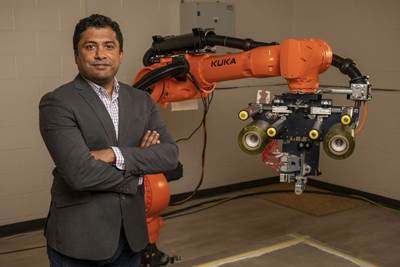

Read MoreClemson Composites Center leads research in low-cost composite tooling

Innovative technology approach to use additive manufacturing and artificial intelligence to produce tools faster, at a lower cost and with less environmental impact.

WatchComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

WatchSolvay launches LTM 350 low-temperature composite tooling prepreg

Carbon fiber epoxy prepreg sets new standards in cost-efficient composite tooling with fast layup, fast initial cure and short post-cure cycles.

Read More3D-printed composite tail rotor gear box housing enhances Discovery super drone

CFP Technology teams with Flying-Cam to create 3D-printed, functional tail rotor actuators protection using Windform XT 2.0 composites and a powder bed fusion process.

Read MoreOne-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

Read MoreUTA research builds predictive tool to determine failure risk, operating life of composites

UT Arlington, AFRL solution will use machine learning and computational tools to determine the life, durability and safety of composites used in aircraft manufacturing.

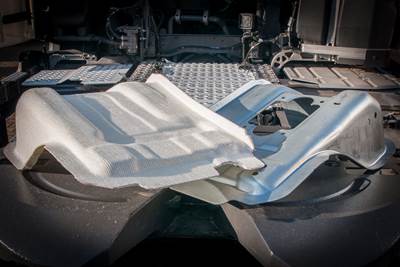

Read MoreWhy does my composite mold leak under vacuum or applied pressure?

Louis Dorworth of Abaris Training Resources outlines key considerations to make when fabricating quality composite molds to minimize risk of leakage under pressure or vacuum.

Read MoreCAMX 2022 exhibit preview: Instron

Featuring gaskets, a patent-pending airflow design, fortified frames, abrasion-resistant coating and more, Instron's 6800 Series systems are designed with composites and other complex materials testing in mind.

Read More