Cutting/Kitting

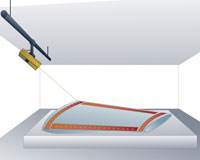

Robotic trimming radically shortens Corvette fender production cycle

Plasan USA (Bennington, Vt.) molds the Chevrolet Z06 Corvette’s front fenders with hand layed, autoclave-cured carbon/epoxy prepreg. Until recently, however, manual deflashing, trimming and drilling of the demolded parts consumed more than an hour to meet requirements for edge quality and fastener hole location

Read MoreManaging multi-axis manufacturing

Much early computer numerically controlled (CNC) machinery served short-run military and space programs where cost per part was too high to be acceptable in the manufacture of commercial aircraft. Now, Automated CNC machinery moves toward volume production and part-specific design.

Read MoreWaterjet cutting system tackles big job, outdoor environment

When Plasti-Fab Inc. (Tualatin, Ore.), a manufacturer of corrosion-resistant equipment for water and wastewater treatment and control, landed a contract to cut hundreds of circles out of 8,000-lb/3,629-kg, 1-inch/25 mm thick rectangular fiberglass plates, the company needed an efficient cutting solution. Tests with a

Read MoreJEC Composites 2006 Product Showcase - 7/1/2006

Advanced composites continue to lead the economic upswing in the composites industry.

Read MoreAircraft Repair Can And Should Be Automated

Consultant Fred Perkins (Federal Engineering Associates LLC, McLean, Va.) is currently involved in quality control and mission assurance for defense programs as well as a Phase I SBIR program for the U.S. Air Force, applying stochastic design analysis to finite element modeling of composite aircraft part repairs.

Read MoreLaser Imaging Material Speeds Aircraft Parts Into Production

A simple product is having a significant impact on composites fabrication at the Boeing Phantom Works' Accelerated Digital Design and Manufacturing (ADDM) group in St. Louis. RegiStar, a trademarked laser-imageable tape from Rohm and Haas Electronic Materials (Marlborough, Mass.), was developed as a marking system for

Read MoreSky's The Limit For Composites-intensive UAVs

Market growth is being spurred primarily by post-9/11 combat actions, homeland security and natural disasters.

Read MoreAutomated Aircraft Repair Closer To Reality

Inspection and Repair Preparation Cell (IRPC) unveiled, revealing progress made toward automated aircraft repair workcells.

Read MoreRobot streamlines finishing of composite antenna covers

Sparks Fiberglass' (Rock Island, Ill.) first order for 50 8-ft/15.2m long fiberglass antenna covers for cellular telephone towers in 1998 kicked off a growth period for the company, in which manufacturing space quickly became scarce. When the company moved to a larger facility, it began looking for alternatives to the

Read MoreThermoplastic composites gain leading edge on the A380

Breakthrough manufacturing process produces lightweight, affordable glass-reinforced PPS J-nose on the worlds largest commercial aircraft wing.

Read More