Core

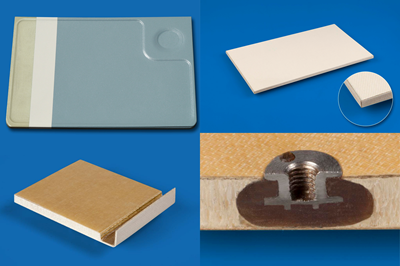

FITS Air thermoplastic sandwich panels enable low-cost, low-weight, sustainable aircraft interiors

FITS Air and FITS Base sandwich panels provide alternative material avenues for aerospace and other industries, including low weight, low part production cost, thermoformability and recyclability.

Read MoreRegent appoints composites builder for seaglider demonstrator

The seaglider technology demonstrator will be able to float, foil or fly along coastal routes with the help of its composite superstructure developed by Moore Brothers Company.

Read MoreSaertex presents SAERfoam structural core materials

Hybrid core material is simple to process, highly economical and exhibits a shear modulus up to four times greater in comparison to PVC and PET.

Watch3A Composites Core Materials commits to sustainable growth, harvesting and processing of balsa wood

The core materials company has signed a two-year technical agreement with the nonprofit Achuar Nationality of Ecuador to achieve enduring development of indigenous communities and responsible forestry.

Read MoreBMComposites installs solar-powered composite hardtop bimini for expedition yacht

Contracted hardtop bimini uses a combination of carbon fiber, glass fiber and foam core as well as 20 SP130 solar panels for a highly sustainable and sleek boat design.

Read MoreLeveraging motorsports composites for next-gen rotorcraft

FastCan consortium integrates hollow, solid and cored CFRP into single-cure, single-piece canopy for reduced weight and cost.

WatchCosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

WatchIndustrial-scale wave energy system enabled by mobile filament winding

Sweden-based CorPower Ocean designed its 9-meter-long, filament-wound GFRP buoy prototype for high-efficiency, durable wave energy generation and fast, on-site manufacture.

WatchStratasys, Champion Motorsport team up to test 3D-printed core technology

Stratasys proves out carbon fiber-wrapped, printed core for toolless, customizable manufacture, on aerodynamic prototype and production parts for a winning racecar.

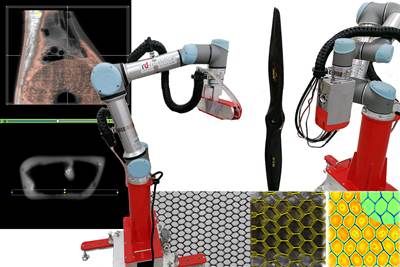

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

Watch