Clean Sky

Saab Aerostructures announces composite cargo door iteration, flaperon developments

Saab Aerostructures has reported updates to two of its composites-related projects, an RTM’d flaperon and the next iteration of the Clean Sky 2 technology demonstrator cargo doors.

Read MoreEU launches Clean Aviation partnership, targeting 75% of civil fleet replaced for zero emissions by 2050

Clean Aviation carries forward from Clean Sky to develop disruptive new technologies, flight demonstrated by 2029 for aircraft into service by 2035 and aviation climate neutrality by 2050.

Read MoreClean Sky 2 FUSINBUL project develops full-scale, carbon fiber pressure bulkheads

Two 3.5-meter pressure bulkhead demonstrators incorporate advanced layup techniques with the goal of increasing serial production capabilities for fuselage manufacture for regional aircraft.

WatchDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

Read MoreSAM|XL develops closed-loop manufacturing for composites

Collaborative R&D center at TU Delft develops sensor- and robot-based automation for Composites 4.0 manufacturing, including STUNNING project for welded assembly of a thermoplastic composite fuselage demonstrator.

WatchLeveraging motorsports composites for next-gen rotorcraft

FastCan consortium integrates hollow, solid and cored CFRP into single-cure, single-piece canopy for reduced weight and cost.

WatchClean Sky 2 FRAMES project advances heating simulation of thermoplastic composite AFP with xenon flashlamp

Heraeus Noblelight and Compositadour develop heating simulation to optimize process temperatures during automated fiber placement of composite aerostructures.

Read MoreMore Affordable Small Aircraft Manufacturing project in Clean Sky 2 replaces metal nacelle with composites

SAT-AM project composite nacelle reduced component weight by at least 10%, reduced the number of elements by more than 35%, resulted in a more uniform structure and reached TRL 6.

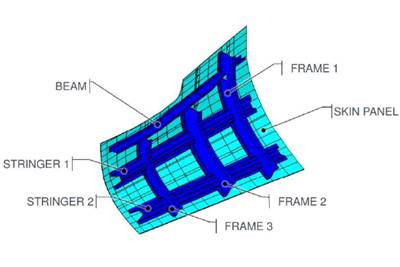

WatchSTUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

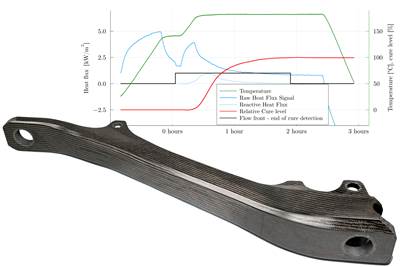

WatchSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read More