Wireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.

Gefran Inc. (North Andover, Mass., U.S.) is introducing the QE2008-W wireless strain measurement system to the North American market for die-casting and injection molding applications. With a sampling rate of up to 1,000 measurements per second, the QE2008-W system accurately and non-invasively measures clamping force, bending and cavity pressure profile to help manufacturers maintain quality control, protect equipment from damage and enable effective communication for production teams.

When paired with Gefran’s Sensormate app, the QE2008-W easily connects to smartphones, tablets and computers, enabling multiple users to quickly capture, analyze and share measurement data. The Sensormate app is downloaded for free from the Microsoft Store, Google Play and Apple App Store, and each QE2008-W system comes with a protective carrying case containing eight sensors that mount magnetically to tie bars.

Gefran’s Sensormate app serves as the digital interface for the QE2008-W system. With a connection to the network, users can locate sensors wirelessly through Gefran’s app and then download measurements as raw data or put the information into a chart. Users can also quickly summarize test values and measurement data into a PDF report, include screenshots, and add comments to give readers contextual details and troubleshooting notes.

The QE2008-W helps with mold alignment so that force is equally distributed, thus minimizing issues such as flashing, plastic deformation or mold damage, and when compared to traditional bonded strain gauges, the QE2008-W installs in minutes. No wiring is required. The sensors connect to the app using Bluetooth technology, and the micro-electro-mechanical (MEM) chips inside the QE2008-W sensors ensure proper placement and orientation. Whenever the QE2008-W is connected to the app, it will also check for firmware updates; sensors are also updated via the app.

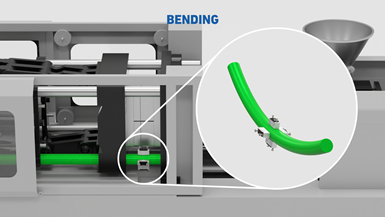

To mitigate the impact of bending forces, the QE2008-W uses four sensors, evenly distributed around the tie bar, mounted at 90-degree intervals. By averaging the readings from these sensors, the QE2008-W measures maximum tension to determine the angle and direction of the bend, achieving greater accuracy of tension and compression measurements for each tie bar.

The QE2008-W’s fast acquisition readings can also measure the cavity pressure profile which is the indirect pressure on tie bars during the injection cycle. Knowing the cavity pressure profile accelerates production efficiency and makes it easier to sustain high product quality.

Related Content

-

CAMX 2022 exhibit preview: Current Inc.

Current Inc. produces thermoset-based products such as tubing rods, sheets and more with high electrical and mechanical characteristics and different color combinations.

-

CAMX 2022 exhibit preview: Gougeon Brothers Inc.

Pro-Set Epoxy offers a variety of standard and customizable epoxy systems to create strong, lightweight and high-performance composites that can withstand harsh environments.

-

What to expect at CAMX 2022

The Composites and Advanced Materials Expo (CAMX), the largest composites industry trade event in North America, takes place Oct. 17-20, 2022 in Anaheim, Calif., U.S.