Solvay launches Xencor XTreme for battery thermal runaway protection

Long glass fiber-reinforced PPA solution, produced with partially bio-based content, provides resistance to thermal runaway and propagation in EVs.

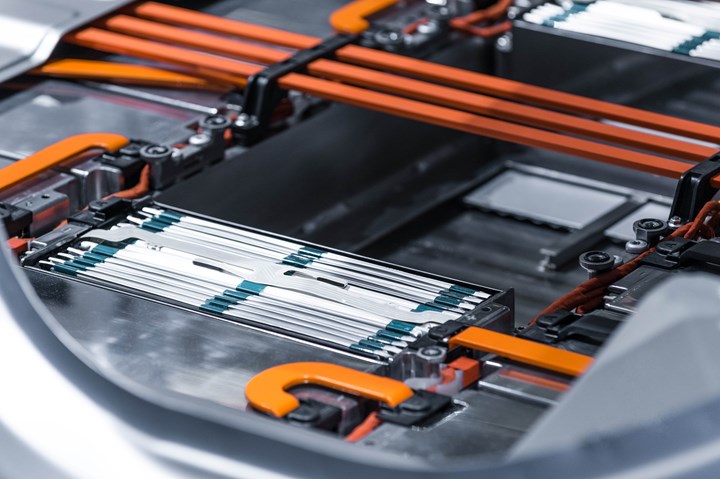

Solvay (Alpharetta, Ga., U.S.), a global supplier of specialty materials, introduces Xencor XTreme, a new family of long glass fiber (LGF) polyphthalamide (PPA) solutions for battery applications requiring resistance to thermal runaway and propagation.

Xencor XTreme PPA LGF grades are designed to offer optimized resistance to direct flame exposure at 1,000°C for more than 10 minutes, providing sufficient time for passengers to exit the vehicle in the event of a thermal runaway, thus meeting the latest global regulations in Europe, China the U.S. and other countries. The materials are designed to retain a high level of electrical insulation after exposure to flame, helping to mitigate thermal runaway in batteries. More importantly, the material has a high glass transition temperature which enables dimensional stability of the parts under battery operating conditions.

“Xencor XTreme is designed for battery components such as overmolded busbars, module end plates and fixtures, and extends our broad portfolio of battery solutions,” Brian Baleno, head of marketing automotive at Solvay, says. “This product range gives engineers the freedom to address some of their biggest challenges in terms of safety, power density, security and lightweighting.”

Key benefits of Xencor XTreme include high stiffness, strength and impact resistance, electrical insulation with a comparative tracking index of >600 volts and high dielectric strength.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

.jpg;maxWidth=300;quality=90)