In-mold coating offers high-performance finishing for epoxy-infused composites

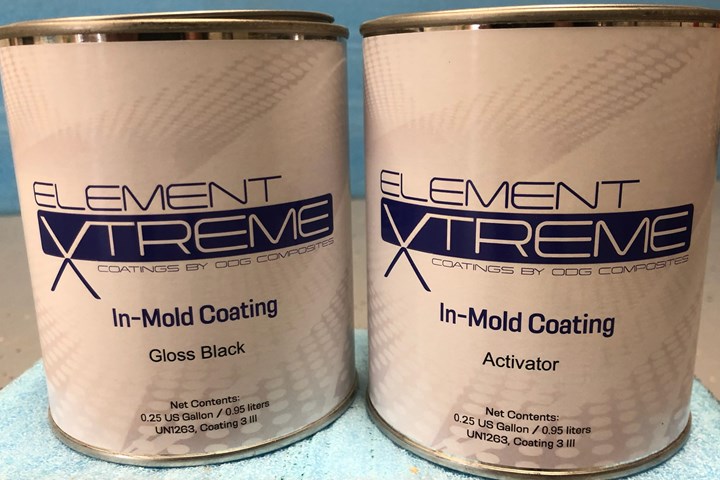

ODG Composites’ Element Xtreme is a lightweight, long-lasting protective and aesthetic coating suitable for a range of industrial and commercial applications.

ODG Composites LLC (Saginaw, Texas, U.S.) has launched Element Xtreme Coatings, a specialty in-mold coating designed for exterior durability, flexibility and adhesion when applied to infused, epoxy-based composite parts.

According to Russ Emanis, founder of ODG Composites, traditional gel coats can account for 15-25% of the total part weight depending on part size. Element Xtreme, sprayed directly into the mold prior to infusion and cure, is said to save weight by up to 50% compared to gel coats. Less coating is required due to the hardness of Element Xtreme.

Available in a wide range of colors, the product has been developed for simple application, fast cure and a Class A finish directly from the mold. Element Xtreme is formulated to last, offering long-term protection in moderate to severe environments; resistance to fresh water, saltwater and many chemicals and fumes; and abrasion and moisture resistance.

Element Xtreme Coatings is said can be applied to any epoxy-infused composite parts in a variety of industrial and commercial end markets, with high utility in the marine industry including fishing kayaks and boat components.

For more information or to order, contact Emanis at (817)-386-0696 or russ@odgcomposites.com, or visit www.odgcomposites.com.

Related Content

-

Mallinda launches Vitrimax VHM resin for complete composites recyclability

Vitrimax VHM enables “infinite” recyclability, self-healing and tunable properties, reducing manufacturing waste and supporting sustainability for high-performance industries.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Norco delivers GFRP hard hulled riverine craft for BAE Systems

Norco’s broad-ranging materials and manufacturing expertise revitalize UK MOD legacy craft, providing a solution for future defense and communications sector projects.

.jpg;width=70;height=70;mode=crop)