Core materials readily accept mechanical fasteners, screws

CAMX 2023: Composite manufacturers are now able to design and build lightweight composite sandwich panels that can “hold a screw” far more easily using 3A Core Materials’ Airex W.I.S.H. core.

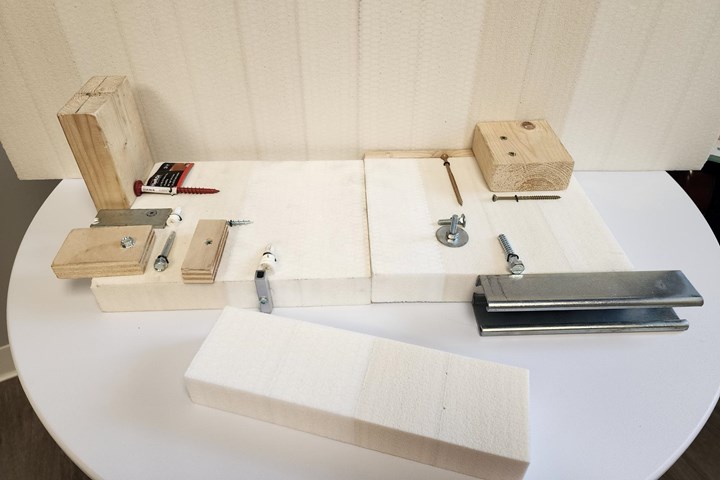

3A Core Materials (Colfax, N.C., U.S.) is introducing Airex W.I.S.H. core for lightweight sandwich panels that can readily accept mechanical fasteners and screws. W.I.S.H., standing for “With Integrated Screw Holding,” is a combination of low- and high-density PET foam to balance high R-values and maximum screw holding. The state-of-the-art technology can be provided in custom lengths, widths and shapes to reduce labor, process time and waste.

W.I.S.H. core’s cost and weight are said to be significantly reduced while the net R-value is fully maximized without any compromise on stiffness or strength. According to 3A Core Materials, customers will no longer have to overdesign their core or composite panels to improve fastener performance.

W.I.S.H. products may also be supplied with its Airex T90 fire resistant PET foam. Lengths up to 16' are available as well as options including our SealX surface finish (reduced resin uptake) and custom configurations for infusion and other processes.

Related Content

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.