CompositesWorld New Products for Jan. 20, 2020

The latest technology from Lambient Technologies, and MasterMover

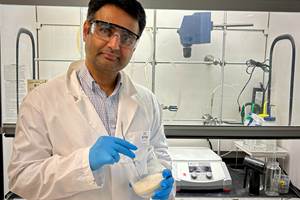

Cure testing services available for suppliers, fabricators

Lambient Technologies LLC now offers cure testing services for companies working with thermoset resins or advanced composite materials.

Precision measurement solutions specialist Lambient Technologies LLC (Cambridge, Mass., U.S.) now provides cure testing services for companies working with thermoset resins or advanced composite materials. According to the company, customers can use this data to identify flaws or inconsistencies in raw materials obtained from outside suppliers, such as variations in curing behavior between batches or within a roll of prepreg material. With data provided by Lambient Technologies, companies can work with suppliers to improve the consistency of raw materials.

Whether an organization needs to test incoming resins or prepreg materials that it receives from suppliers or needs to test consistency of outgoing materials that it is supplying to other companies, Lambient Technologies says its testing services provide researchers with critical information about the curing of their materials, illustrating the effect of formulation and different time-temperature schedules on cure and cure time.

In addition, customers can submit material samples before engaging in testing services, incurring no charges if Lambient Technologies determines that the material is one that cannot be measured with its equipment. If customers engage in testing services and then decide to purchase one of Lambient’s DEA instruments, a portion of the testing expenditure will be applied to the cost of an instrument.

In addition to its testing services, Lambient Technologies designs, produces and sells instruments for real-time analysis of the curing of thermosets and advanced composite materials such as those used in aerospace, automotive and wind applications.

Electric tugs ease loading of aerostructures in and out of autoclave

The MasterMover MT600+ electric tug is said to enable an operator to easily push, pull and steer wheeled loads up to 6,000 kilograms.

Source | MasterMover

The MasterMover (Ashbourne, U.K.) MT600+ electric tug, part of the company’s MasterTug range, reportedly enables a single operator to easily push, pull and steer wheeled loads up to 6,000 kilograms.

According to the company, operators at aerospace manufacturing facilities can use the MT600+ to more easily load and unload composite materials from an autoclave, saving time and minimizing risk of injury compared to moving with trolleys and other methods. The MT600+ reportedly enables maximum control over load movement, reducing potential for damage to materials and components.

According to MasterMover, aerospace parts manufacturer KCI Composites Inc. (KCI; Sacheon, South Korea) had previously used a trolley to move 6-tonne composite aircraft parts in and out of the autoclave, but experienced issues related to the lack of ability to control the load on the trolley while pulling the trolley out of the autoclave. MasterMover’s sales partner Sung Wong Co. completed a site evaluation at KCI’s plant in Sacheon, and recommended an MT600+ as the ideal solution.

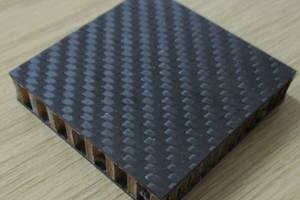

Reliabotics introduces carbonic cleaning systems

Reliabotics has introduced to the composites market a line of CO2-based cleaning products designed to provide fast, highly efficient, waste-free cleaning of a variety of surfaces, including molds and finished composite parts and structures.

Reliabotics carbonic cleaning system. Source | Reliabotics

Reliabotics (New Brunswick, N.J., U.S.), in collaboration with CleanLogix and Hitachi High-Tech, has introduced to the composites market a line of CO2-based cleaning products designed to provide fast, highly efficient, waste-free cleaning of a variety of surfaces, including molds and finished composite parts and structures. Called carbonic cleaning, the technology is similar to dry ice cleaning, but uses CO2 delivered from a bulk tank and into a nozzle system that jets CO2 particles onto a surface to dislodge contaminants. The CO2 tanks require no manual loading and the nozzle uses thermodynamics to change CO2 particle size. Further, as with dry ice cleaning, CO2 particles the carbonic system sublimate immediately after impact and produce no VOCs or waste.

The products Reliabotics manufactures fall into two categories. The first is the CO2 delivery module, and for this the company offers the CM-1 and the CM-2. CM-1 is a portable, robot-ready tabletop model that uses beverage-grade CO2 and is designed for small parts/applications. CM-2, designed for larger applications, uses gas-bulk and micro-bulk CO2 and offers network and IO connectivity.

The second product type is the nozzle. Nozzle CE-3, compatible only with the CM-1 delivery module, offers a 1-inch cleaning footprint and consumes up to 12 lb/hr of CO2. Nozzle CE-6, compatible with CM-1 and CM-2, offers a 2-inch cleaning footprint and consumes up to 24 lb/hr of CO2. Nozzle CM-10, compatible with CM-2 only, offers a 5-inch cleaning footprint and consumes up to 40 lb/hr of CO2.

Reliabotics representatives say that its carbonic systems are designed to complement surface preparation systems — like plasma or corona treatment — that require a clean surface prior to preparation. To that end, representatives add that it is possible to combine a Reliabotics carbonic cleaning system with a plasma or corona treatment system in one robotic end effector, enabling cleaning and surface prep in a single pass. Reliabotics says the only material its carbonic system cannot remove is silicone. Reliabotics' technology and products are proven in the automotive, biomedical and electronics industry and are now being targeted toward composite surface preparation and high-reliability bonding applications in aerostructures.

For more information, contact Ahsan Anwar, surface specialist and product manager at Reliabotics.

Related Content

XlynX Materials introduces PFAS-free BondLynx molecular adhesive

Improved version of BondLynx eliminates fluorine for a more sustainable adhesive option, while still outperforming conventional adhesive bonding strength.

Read MoreScott Bader partners with Elixir for Crestabond distribution in India

Crestabond MMA structural adhesives range will continue to drive advanced composites growth in India, in addition to Scott Bader’s global expertise and local technical support.

Read MoreScott Bader ATC begins Crestabond MMA structural adhesive production

Scott Bader’s Drummondville, Canada, facility has begun manufacturing and supplying composites-applicable adhesives to its North American customers.

Read MorePRF Composite Materials introduces primer, adhesive films

Novel RFA570 eXpress cure adhesive film and RF Primer are compatible with PRF’s full range of epoxy prepregs formulations.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;width=70;height=70;mode=crop)