Specialized carbon fiber, thermoplastics and thermosets portfolio

CAMX 2023: Toray Group and its subsidiaries are bringing full-scale application examples to CAMX, highlighting the company’s vast composite material offerings.

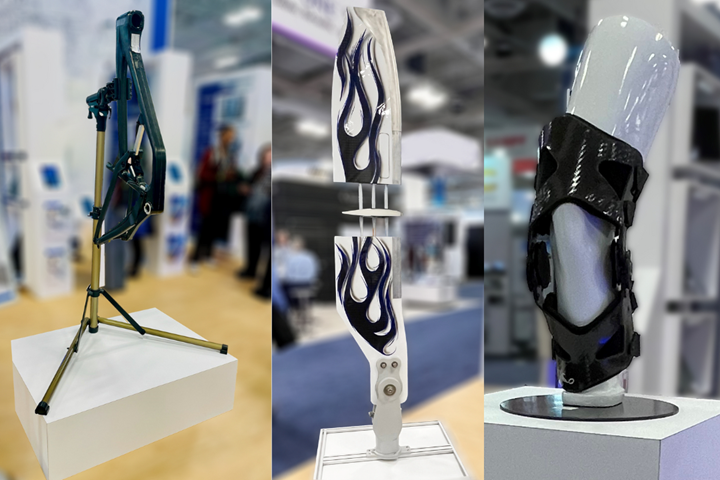

Mountain bike (left), main rotor blade (center) and knee brace (right) application examples. Photo Credit: Toray Group

Toray Group (Tokyo, Japan) is highlighting full-scale part applications that use its suite of composite materials. Toray’s specialized product portfolio includes Torayca carbon fiber and advanced thermoplastic and thermoset composites materials.

Toray Composite Materials America’s (TCMA, Tacoma, Wash., U.S.) 2510 thermoset prepreg system is specifically formulated for out-of-autoclave (OOA) processing for aerospace structures. Commonly paired with Torayca T700 standard modulus fiber, this prepreg system offers optimal, all-around structural properties with high wet and dry Tg and low-energy curing.

The main rotor blade display at Toray’s booth uses 66 plies of plain weave fabric and unidirectional (UD) carbon fiber tape. Use of the material is reported to provide high fatigue properties for long service hour life and corrosion resistance.

Other sample parts incorporate the company’s 3960 prepreg system, a highly toughened, 350°F/177°C cure epoxy resin. Combined with Torayca T1100 intermediate modulus plus carbon fiber — said to be the highest tensile strength carbon fiber to date — this prepreg system is optimized for increased performance and enables autoclave and OOA curing.

Toray Advanced Composites’ (TAC, Morgan Hill, Calif., U.S.) Cetex suite of high-performance thermoplastic composite materials exhibits improved mechanical properties and processing advantages and is claimed to be the first globally recognized, NADCAP-accredited, high-performance thermoplastic within the industry.

Cetex TC910 offers an good balance of strength and impact resistance, making it ideal for housings and under-the-hood applications. Switching high-performance mountain bikes from aluminum to TC910 thermoplastic prepreg offers improvements in damage tolerance, ride quality and environmental factors, TAC reports. The material is moldable and formable and has good elevated temperature resistance.

Other materials include TC380 epoxy prepreg, ideal for next-generation aerospace innovations such as the quickly evolving eVTOL/UAM markets. TC380, setting a new benchmark for toughed prepreg systems, facilitates the construction of large or complex composite parts and assembly.

CFRT TL-6000, a strong and stiff composite sheet material from Toray Performance Materials Corp. (TPMC, Camarillo, Calif., U.S.), represents the effective transfer of technology from high-performance aerospace systems to lightweight orthotics. TL-6000 is offered in various grades, ranging from two- and three-layer fabric. The addition of a third layer significantly increases stiffness while adding only 1/32" thickness.

Additionally, TPMC is announcing the approaching commercialization of its closed-loop recycling process. By reclaiming its own scrap from composite skeletons and production scrap, TPMC is developing a solution to waste that was previously sent to landfills. The company is also producing a variety of recycled offerings for customers, including what it claims is the first of its kind for recycled fiber-reinforced polymethyl methacrylate (PMMA) compound.

Related Content

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.