Virgin Galactic reaches new heights, adds third passenger with second spaceflight

The flight marks the highest altitude and speed that the SpaceShipTwo has achieved to date, and included the addition of a third crew member for the first time.

Virgin Galactic (Las Cruces, N.M., U.S.) conducted its fifth powered test flight and second spaceflight of its commercial SpaceShipTwo, VSS Unity, above Mojave, Calif., U.S. on Feb. 22. The spacecraft achieved several firsts, including its highest speed and altitude to date as well as, for the first time, carrying a third crew member on board along with research payloads from the NASA Flight Opportunities program.

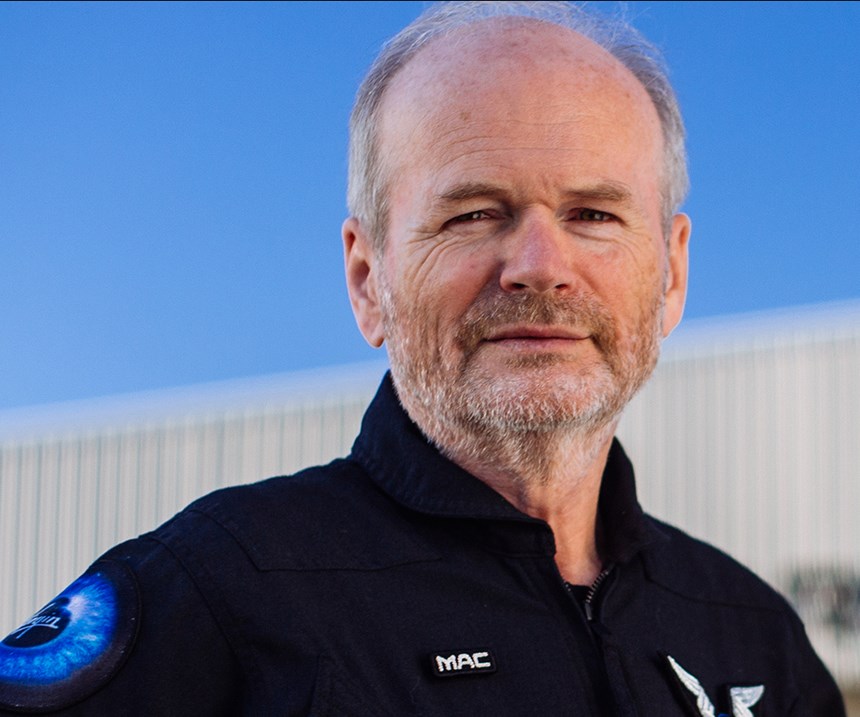

As of this spaceflight, chief pilot Dave Mackay and co-pilot Michael “Sooch” Masucci become commercial astronauts and the 569th and 570th humans in space. Beth Moses, Virgin Galactic’s chief astronaut instructor, flew as the third crew member in a first, live evaluation of cabin dynamics. She is the 571st person to fly to space and the first woman to fly on board a commercial spaceship.

In addition to this element of envelope expansion, VSS Unity flew higher and faster than it had before, as its hybrid rocket motor propelled the spaceship at Mach 3.04 to an apogee of 295,007 feet. (See CW’s coverage of the making of the carbon fiber spacecraft.)

The flight was also a test of what customer experience might be like in the ship’s cabin. During several minutes of weightlessness while the pilots “feathered” the spaceship in preparation for a Mach 2.7 re-entry, Moses floated free to complete a number of cabin evaluation test points. The human validation of data previously collected via sensors, and the live testing of other physical elements of the cabin interior, are fundamental to the provision of a safe but enjoyable customer experience, Virgin Galactic says.

The flight was the first time that a non-pilot flew on board a commercial spaceship to space, and it was the first time that a crew member floated freely, without restraints, in weightlessness in space onboard a commercial spaceship.

The ship’s glide back to land was followed by a smooth runway landing, and the crew was received by a crowd on the flight line that included staff and some of Virgin Galactic’s 600 Future Astronaut customers. Mackay, the first Scottish-born astronaut and an ex-RAF test pilot and Virgin Atlantic captain, led his crew of newly qualified astronauts from VSS Unity accompanied by a kilted piper.

“Beth, Sooch and I just enjoyed a pretty amazing flight which was beyond anything any of us has ever experienced,” said Mackay after the landing. “I am incredibly proud of my crew and of the amazing teams at Virgin Galactic and The Spaceship Company for providing a vehicle and an operation which means we can fly confidently and safely. For the three of us today, this was the fulfillment of lifelong ambitions, but paradoxically is also just the beginning of an adventure which we can’t wait to share with thousands of others.”

“Flying the same vehicle safely to space and back twice in a little over two months, while at the same time expanding the flight envelope, is testament to the unique capability we have built up within the Virgin Galactic and The Spaceship Company organizations,” says Virgin Group founder Richard Branson. “I am immensely proud of everyone involved. Having Beth fly in the cabin today, starting to ensure that our customer journey is as flawless as the spaceship itself, brings a huge sense of anticipation and excitement to all of us here who are looking forward to experiencing space for ourselves. The next few months promise to be the most thrilling yet.”

Related Content

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreThe next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreRead Next

One step closer to commercial spaceflight

CW senior writer emeritus Donna Dawson provides an eyewitness account of the launch and safe return to Earth of Virgin Galactic’s SpaceShipTwo on the day of its first spaceflight.

Read MoreLeveraging composites for space tourism

Virgin Galactic’s WhiteKnightTwo will carry its SpaceShipTwo to launch position, then rocket passengers to suborbital space for a heavenly view of Earth.

Read More

.jpg;width=70;height=70;mode=crop)