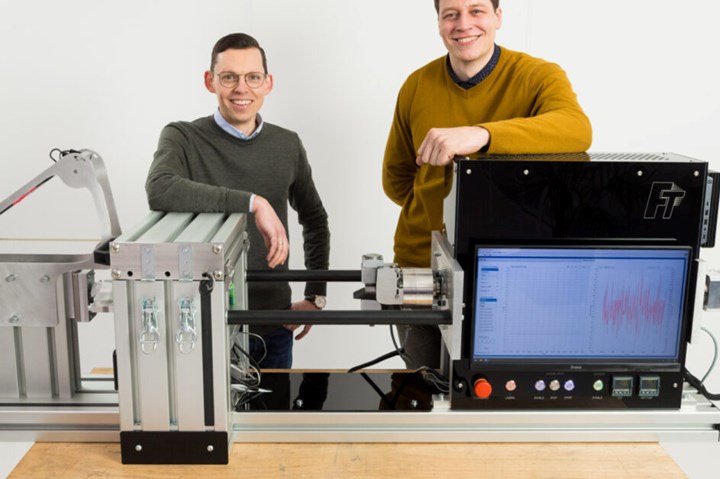

Thermoplastic tape friction tester completed at TPRC

Delivered and implemented at Toray Advanced Composites, the setup seeks to eliminate defects during hot press forming thermoplastic tapes.

The ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands) has recently highlighted the completion and delivery of a novel friction tester for thermoplastic matrix composite tape in melt to Toray Advanced Composites (Nijverdal, The Netherlands). The completed setup provides a better understanding of the friction behavior of thermoplastic composites in melt, to avoid the occurrence of defects during hot press forming of the material.

The development of the friction tester was achieved by TPRC doctoral student Rens Pierik and University of Twente researcher Sam Benou as part of the press forming without defects (PERFECT) project. The test setup measures the resistance against sliding of adjacent plies to simulate what happens during press forming of thermoplastic composites.

Earlier research, as part of the PERFECT project, revealed insights into the ply-ply friction of UD C/PAEK tapes, to be used as a basis for future constitutive modeling. More about this work can be viewed here.

The Dutch Research Council (NWO) supports this research project.

For related content, also read:

- TPRC research project investigates thermoplastic composite structure repair strategies

- TPRC research studies void removal mechanisms in VBO processing

Related Content

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.