Teijin Automotive Technologies supplies exterior body panels to Lotus Emira

The new premium sports car features exterior doors and panels made from Teijin Automotive Technologies’ compression molded TCA Ultra Lite material.

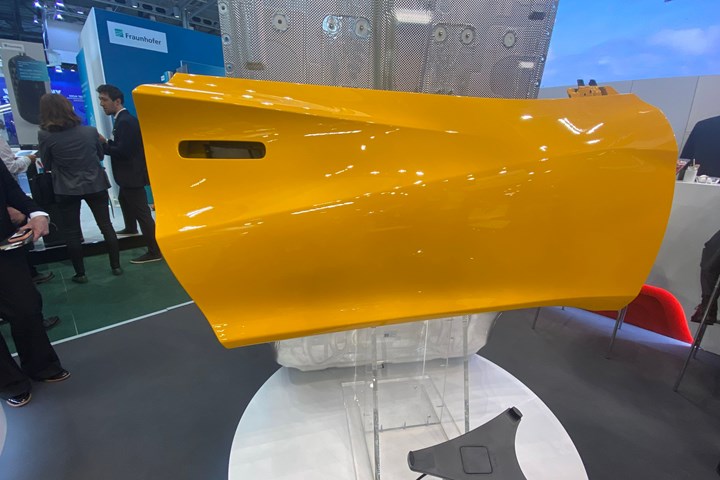

The exterior styling of the all-new mid-engine premium sports car Lotus Emira is made possible, in part, by the advanced composite exterior panels provided by Teijin Automotive Technologies (Auburn Hills, Mich., U.S.). Specifically, Teijin Automotive Technologies announces that it is providing the right- and left-hand doors; right- and left-side rear quarter panels, and the inner, outer and lower shells of the tailgate.

The doors, rear quarter and tailgate outer panels are manufactured using the company’s proprietary TCA Ultra Lite material. This low-density, Class A surface material is reported to be up to 43% lighter than a traditional composite material, and approximately the same weight as aluminum. However, because it is a compression-molded composite, it can achieve dramatic styling cues not possible with a stamped metal and is dent and corrosion resistant. This award-winning material is being produced on the company’s state-of-the-art sheet molded compound (SMC) compounding line in Pouancé, France.

Specific design cues include a sculpted section in the door that leads airflow toward the intake, which is molded into the rear quarter panel. This design serves a dual purpose, providing air intake and cooling for the engine bay.

“The body panels of the Lotus Emira had to satisfy a number of requirements including aerodynamic design and styling, but also have to be lightweight, strong and provide a high-quality Class A finish,” says Paul Tedstone, executive director of supply for Lotus Cars. “By using lightweight composites for the body panels, including the doors, we were able to combine all the engineering and styling requirements in the stunning design of this award-winning sports car.”

The inner panels for the tailgate are made from a structural grade, low-density SMC, featuring a glass fiber content optimized for strength. All outer panels are provided to Lotus with a conductive primer, and the interior tailgate panel is provided with a black texturized coating. All components are being manufactured at the Teijin Automotive Technologies facility in Leça do Balio, Portugal.

“To have the opportunity to be a part of this iconic vehicle brand, bringing an all-new, dynamic sports car to the market has been exciting for us,” says Chris Twining, CEO, Teijin Automotive Technologies. “Our Class A ultra-light composite materials enhance both the appearance and performance of this exotic-looking, premium vehicle.”

Teijin Automotive Technologies’ Ultra Lite technology uses proprietary, treated glass bubbles to replace some of the CaCO3, allowing the resin to adhere to the matrix and increase the interfacial strength between the bubble and the resin. This treatment technology results in a more robust resin mix making molded parts more resistant to handling damage, preventing micro-cracks that cause paint pops, pits and blistering, and improving paint adhesion and bonding characteristics.

TCA Ultra Lite is said to offer automakers an opportunity to achieve a Class A finish with a material that is resistant to corrosion, dents and dings, ultimately providing the consumer with a vehicle that doesn't rust and won't be subject to the scratches and dings that mar the surface of any vehicle panel made of metal.

Related Content

-

Multi-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)