Study demonstrates improved abrasion resistance using TFP aramid nonwovens

Study shows aramid veil acts as a sacrificial layer to protect the underlying reinforcement, improves durability and extends composite structure lifespan.

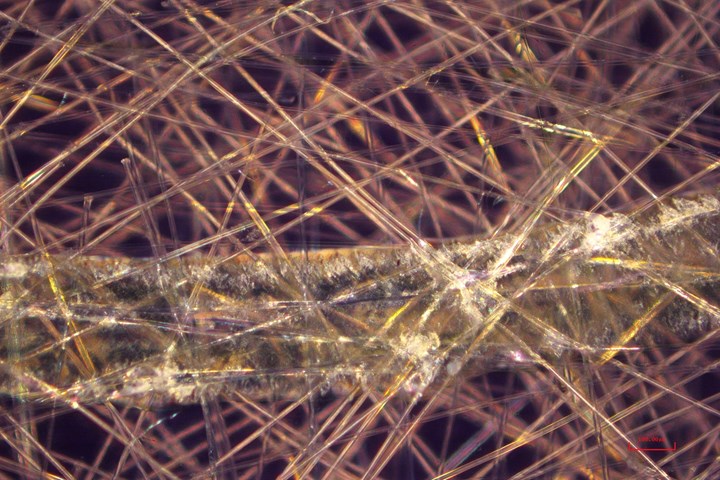

This image shows the composite with the TFP aramid veil after testing. Photo Credit: TFP

Technical Fibre Products (TFP, Burneside, U.K.) reports that a recent study on the use of its aramid nonwoven materials in composite surfacing applications has demonstrated their effectiveness in protecting the underlying structural elements of a composite from the effects of abrasion or wear.

According to TFP, the lightweight aramid veils enable a high-quality surface finish, while simultaneously providing a durable and sacrificial layer in applications such as high-speed composite rollers, automotive friction substrates or sporting goods where the composite experiences a constant friction. Continuous wear, says TFP, can potentially have a detrimental impact on the performance of the composite, as well as significantly reducing the product’s lifespan.

The study carried out examined the effectiveness of using a surfacing veil to increase wear resistance by comparing composite panels fabricated both with and without TFP’s aramid veils. The panels (based on epoxy resin and woven carbon fiber) were tested using a pin-on-disk tribometer to measure friction and wear as a function of time. The data generated demonstrated that the measured coefficient of friction (COF) is significantly lower when an aramid surfacing veil is used, taking at least five times as long to reach the level measured in the control. Essentially, TFP says this indicates that the level of friction experienced by the composite surface is significantly lower and less material is worn away as a result.

This finding has been reinforced by microscope imaging of the samples, which only show damage — and no breakage — to the surface fibers, and no damage to or exposure of the woven reinforcement in the composite panels containing aramid surface veil. TFP notes that this can be compared to the evidence of significant fiber breakage and damage to the underlying carbon fiber weave in the control panel.

Ultimately, the findings are said to demonstrate the importance of the aramid veil in acting as a sacrificial layer to protect the underlying reinforcement, increasing durability of the composite structure and extending its lifespan. More information on the study (including data and images) can be found here.

In addition to abrasion resistance, TFP’s nonwovens are used to confer a wide range of composite functionalities, including conductivity or EMI shielding (via metal-coated veils), corrosion resistance (glass or carbon fiber) and fire protection (with Tecnofire). The company’s nonwovens are also widely used as surfacing veils, and ensure uniform resin uptake, elimination of dry spots, minimized print-through and fiber breakout and deliver a high-quality surface finish.

Related Content

-

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

-

Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.