Six nominees chosen for Cellulose Fibre Innovation of the Year 2022 award

Cellulose fiber solutions, chosen by International Conference on Cellulose Fibres conference advisory members, range from cellulose made of orange and wood pulp, to a novel technology for cellulose fiber production.

Photo Credit: nova-Institut GmbH

For a second year in a row, nova-Institute GmbH (Hürth, Germany) announces the six nominees under the “Cellulose Fibre Innovation of the Year” innovation award, to be held at the International Conference on Cellulose Fibres hybrid event Feb. 2-3, 2022. Ranging from cellulose made of orange and wood pulp, to a novel technology for cellulose fiber production, initial nominees were chosen by the conference’s advisory board. Winners will be elected by the conference audience on the first day, followed by an award ceremony.

The International Conference on Cellulose Fibres will be offering attendees information on opportunities for cellulose fibers through policy assessment, a session on sustainability, recycling and alternative feedstocks as well as latest developments in pulp, cellulose fibers and yarns. This includes application such as nonwovens, packaging and composites.

The six nominees are as follows:

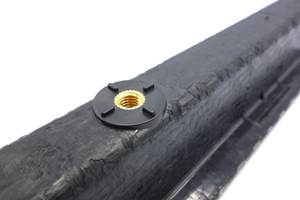

Carbon fibers from wood: German Institutes of Textile and Fiber Research Denkendorf (Germany)

This institute’s HighPerCellCarbon technology is said to be a sustainable and alternative process for the production of carbon fibers made from wood. The technology starts with wet spinning cellulosic fibers using ionic liquids (IL) as direct solvent in an environmentally friendly, closed-loop filament spinning process (HighPerCell). These filaments are then directly converted into carbon fibers via a low-pressure stabilization process, followed by carbonization. It is noted that no exhaust fumes or toxic byproducts are formed during the entire process. Furthermore, the approach allows a complete recycling of solvent and precursor fibers.

Fibers365, truly carbon-negative virgin fibers from straw: Fibers365 (Germany)

According to Fibers365, its product is the first carbon-negative virgin straw fiber on the market. The Fibers365 concept is based on a state-of-the-art process to provide functional, carbon-negative and competitive non-wood biomass products such as virgin fibers for paper, packaging and textile purposes as well as high-value process energy, biopolymer and fertilizer side streams. The products are extracted from the stems of annual food plants such as straw by a chemical-free, regional, farm-level steam explosion pulping technology, allowing an easy separation of the fibers from sugars, lignin, organic acid and minerals. In the case of annual plants, Fibers365 says CO2 emissions are recaptured within 12 months from their production date, offering “instant,” yearly compensation of corresponding emissions.

Iroony hemp and flax cellulose: RBX Créations (France)

Iroony is a branded cellulose made by RBX Créations from hemp. This resistant hemp plant grows quickly within in a few months, captures carbon and displays a high content of cellulose. The biomass is directly collected from French farmers who cultivate without chemicals or irrigation, in extended rotation cycles, contributing to soil regeneration and biodiversity. For a diversified supply, the hemp can be combined with organically grown flax.

Through its patented process, RBX Créations says it extracts high-purity cellulose, suitable for spinning technologies such as the DITF research center’s HighPerCell technology (mentioned above). The resulting fibers are said to display versatile properties of fineness, tenacity and stretch, for applications like clothing or technical textiles. Iroony combines low impact, trackability and performance.

Spinnova, sustainable textile fiber without harmful chemicals: Spinnova (Finland)

Spinnova’s innovative technology is said to enable production of sustainable textile fibers in a mechanical process, without dissolving or any harmful chemicals. The process involves the use of paper-grade pulp and mechanical refining to turn pulp into microfibrillated cellulose (MFC). The fiber suspension consisting of MFC is extruded to form textile fiber without regeneration processes. The Spinnova process does not generate any side waste, and the environmental footprint of the technology includes 65% less CO2 emissions and 99% less water compared to cotton production. Spinnova’s solution is also scalable: It targets to reach one million tonnes annual production capacity in the next 10-12 years.

Tencel-branded lyocell fiber made of orange and wood pulp: Orange Fiber (Italy)

Orange Fiber is reported to be the world’s first company to produce a sustainable textile fiber from a patented process for the extraction of cellulose to be spun from citrus juice leftovers; more than one million tonnes of citrus juice waste is produced in Italy alone.

The result of its partnership with Lenzing Group (Austria), a global producer of wood-based specialty fibers, is the Tencel-branded lyocell fiber made of orange and wood pulp. The novel cellulosic fiber, part of the Tencel Limited Edition initiative, is characterized by soft appeal and high moisture absorbance and has already obtained the OEKO-TEX Standard 100 certificate and is undergoing a diverse set of other sustainability assessments.

The sixth nominee from Kelheim Fibers (Germany) contributes to the functionalization of plant-based and biodegradable fibers for reusable hygiene textiles.

The nova-Institute would like to thank Lenzing, Kelheim Fibres, and Birla Cellulose (India) for supporting the conference as Gold Sponsors as well as Levaco Chemicals (Germany) as Silver Sponsor.

Many thanks also go to the conference partners: BCNP Consultants (Germany), C.A.R.M.E.N. (Germany), canopy (Canada), CLIB (Germany), IBB-Netzwerk (Germany), ITA – RWTH Aachen (Germany), kunststoffland.NRW (Germany), Renewable Carbon Initiative (Germany), Russian Textile Association (Russia), Textile Exchange (USA), World Bioeconomy Forum (Finland), and The Fiber Year (Switzerland).

Related Content

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreAugmenting engineered thermoplastics with natural fibers

The Paris Climate Accord mandate for net-zero carbon by 2050 has kick-started an innovation revolution for natural fibers and sustainably engineered resins.

Read MoreRead Next

Renewable Materials Conference 2021 announces innovation award winners

Three winning innovations include a hemp fiber and thermoset bioresin chair collection, PET bottles made from enzymatically recycled textile waste and CO2-based household cleaners.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)