SHAPE Machining, Supernatural-X collaborate on composite electric guitar

Made from reclaimed carbon fiber, the lightweight guitar possesses excellent tuning stability, and zero RF interference.

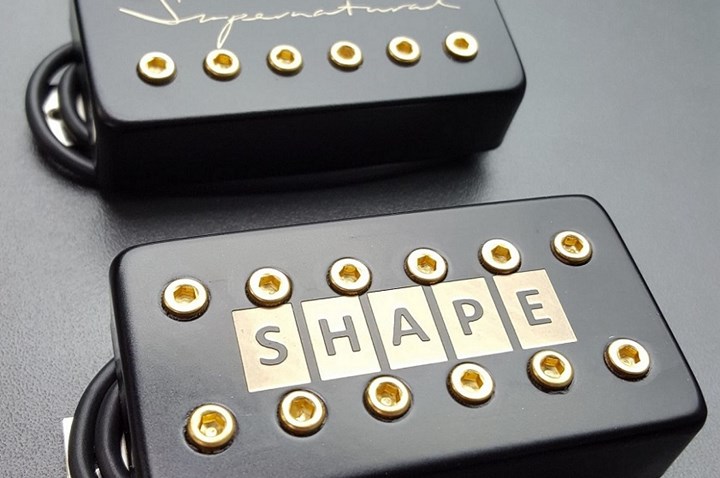

Pick-ups to be placed into the guitars. Photo Credit: SHAPE Machining

SHAPE Machining Ltd. (Witney, U.K.) is working with carbon fiber composite manufacturer, Supernatural-X Ltd. (West Sussex, U.K.), to develop a composite electric guitar, made from reclaimed carbon fiber.

“We are delighted to be working with Supernatural-X to create an electric guitar like no other on the market,” says Ryan Muller, managing director of SHAPE. “The guitar will be made from reclaimed off-cuts during the kitting process of traditionally-made carbon fiber prepreg parts and machined by SHAPE. We are excited to use our automotive and motorsport expertise to branch out and machine carbon fiber for other applications. Typically the off-cuts from the kitting process would be scrapped and sent to the landfill.”

SHAPE says it will design and manufacture the vacuum CNC jigs followed by the machining of the body itself. Supernatural-X is supplying the body and will lacquer the guitar.

According to Muller, “making an electric guitar in carbon fiber has many advantages, including tuning stability, the ability to make the body lightweight, resistance to changes in heat and humidity and many more. The material itself also allows for zero RF interference, meaning the guitar has virtually zero self-noise.”

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Composite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

-

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.