RCCF of TU Dresden develops next-gen, 3D-printed structural supercapacitors

Thales Research and Technology leads PRINTCAP project for more sustainable fast-charging, structural energy storage for automotive and aerospace industries using multifunctional composite materials

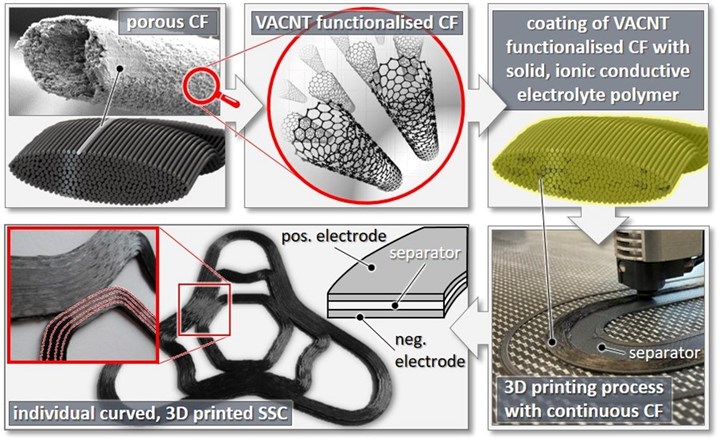

Technology concept for the 3D continuous fiber-printed, free-form, structure-supporting PRINTCAP supercaps. Photo Credit: RCCF at TU Dresden

The “Next Generation of 3D Printed Structural Supercapacitors” (PRINTCAP) research project, led by four partners, including the Research Center Carbon Fibers Saxony (RCCF) of TU Dresden (Germany), and under the chairmanship of Thales Research and Technology (Palaiseau, France), addresses the development of a new generation of supercapacitors (SC) for fast-charging, structural energy storage for the automotive and aerospace industries through the incorporation of 3D printing and multifunctional composites. Since its kick-off in July 2022, partners have jointly discussed possible manufacturing routes and initial concept ideas, and have successfully defined first process steps. The project timeline runs June 2022 to May 2025.

Electric vehicles (EVs), free of local CO2 emissions, form the backbone of the EU’s 2030 climate framework. However, current energy storage systems used, especially batteries, increase vehicle weight to a considerable extent, and limit the freedom in vehicle design. Moreover, existing energy storage solutions are made of layers and stacking methods, which require shielding housings. Therefore, their integration often takes up valuable installation space.

Innovative structural supercapacitors (SSC), however, combine the energy storage function of SC with the high mechanical properties of lightweight composites — addressing weight reduction and opening up space. The SSC concept is said to open up a wide field of concrete applications such as fast-charging electric cars or parcel drones that store energy in their own chassis.

The PRINTCAP project is pursuing the production of SSC via additive manufacturing (AM) processes, to develop a near-neat shape SSC concept that combine weight- and space-optimized lightweight structures with the energy storage function. For direct transfer to industry, PRINTCAP aims to develop effective design and manufacturing concepts for structure-bearing, free-formed SSC, ranging from the concept phase to demonstration proof. The developed concepts will also include initial solutions for recycling the materials used, as well as lifecycle analysis (LCA) studies, in accordance with the cradle-to-cradle principle.

For this purpose, PRINTCAP draws on the expertise of the Research Center Carbon Fibers Saxony (RCCF) at the TU Dresden, among others. In addition, the Leipzig University of Applied Sciences (HTWK, Leipzig, Germany) is contributing its specialist knowledge in the composite design of multifunctional materials. Thales Research and Technology and NAWA Technologies (Aix-en-Provence, France) complement the team’s competencies with technological positions in the field of structural load-bearing electrolytes and the production of carbon nanotube (CNTs) based supercaps. With the synergetic combination of energy storage and lightweight construction, the PRINTCAP project reportedly lays the foundation for the free-form production of fast-charging, structure-supporting, resource-efficient energy storage devices.

Related Content

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreRead Next

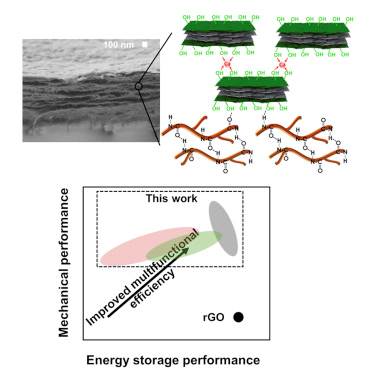

Multifunctional composites could help achieve structural supercapacitors for EVs

In a recent study, functionalized graphene/nanofiber electrodes showed 2X modulus, strength and 5-10X multifunctional efficiency.

Read MoreCAELESTIS R&D project explores predictive design, manufacturing for aerospace

Over 42 months, 11 partners will work together to develop an end-to-end digital thread to effectively enable dataflow across the entire aircraft value chain, accelerating the optimization of disruptive aircraft and engine configurations.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More