Permali develops fire-resistant systems for naval vessels

Permali has developed Permaglass XGR2/4, a new specialist fire-resistant composite material grade that passes strict Ministry of Defence regulations.

Permali (Gloucester, U.K.) designs and manufactures high-strength, glass fiber-reinforced (GRP) composite stanchions, guardrails, deck safety net frames and ladder systems for naval warships and support vessels.

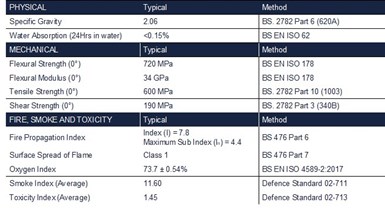

To meet the latest U.K. Ministry of Defence (MoD) regulations, Permali’s R&D team has developed Permaglass XGR2/4, a new specialist fire-resistant (FR) composite material grade. Defence Standard 07-247 is the latest, more stringent MoD fire, smoke and toxicity (FST) performance standard for naval vessels. Permaglass XGR2/4 achieved the highest overall Category A1 rating possible for this enhanced FST Def standard; critical XGR2/4 fire test coupons achieved Class 1 for surface spread of flames (to BS 467 Part 6) and a fire propagation index (I) of 7.8 (to BS 467 Part 7).

Permali’s new Permaglass XGR2/4 resin grade and laminate system achieves this higher FST rating while still meeting the demanding mechanical performance requirements of the MoD standard. Permali has been able to do this by combining its proprietary high-performance, low volatile organic compound (VOC) thermoset FR resin formulation with woven glass reinforcements. Typical mechanical properties include a flexural strength of 720 MPa (to BS EN ISO178) and a tensile strength of 600 MPa (to BS 2782 Part 10:Method 1003).

Current naval vessels in service fitted with Permali supplied deck safety systems include: Visby class corvettes; RN Type 45 destroyers and Type 23 frigates; RFA Bay class support ships; and the Queen Elizabeth-class aircraft carriers, said to be the biggest, most advanced warships built for the Royal Navy. In addition to naval ships, the specialist polar exploration vessel, the RRS Sir David Attenborough, is also fitted with Permali deck safety systems to protect personnel while on the flight deck.

The use of a GRP composite material for stanchions, guardrails and net frames reportedly provides key in-service benefits over metallic alternatives, says Permali, including being lightweight, vibration free, corrosion resistant, low maintenance and non-conductive. For warships, Permali’s composite stanchions produce a significantly reduced radar detection signature.

According to the company, Permali offers a complete range of durable deck or hull mounted modular GRP composite stanchion designs to provide rigid guardrails, Parafil synthetic rope guardrails and safety nets or removable chains. Four standard stanchion styles are manufactured to accommodate the different types of vessels and deck area safety requirements:

- Type A stanchions (for fixed position guardrails)

- Type B stanchions (can fold fore and aft of the deck)

- Type D stanchions (fold onto the deck)

- Quick Release/Removable stanchions (for access areas)

Stanchion systems are supplied by Permali complete with all the stainless steel deck base fixings, positive lock fittings and lug bolts specified for guardrail and net system designs. All fabricated composite stanchions, rigid guardrails, “quick release” lift off gates and deck safety net frames are finished in-house with a two-part paint system. Lift off gates are installed to provide easy access to specific deck areas for “over the side” replenishment at sea (RAS) and to enable unobstructed helicopter maintenance.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More