Metyx signs multi-year agreement with global wind blade supplier

Supply of E-glass, carbon fiber, core and fabric kit, consumables and component to generate €100 million turnover for the Metyx Group.

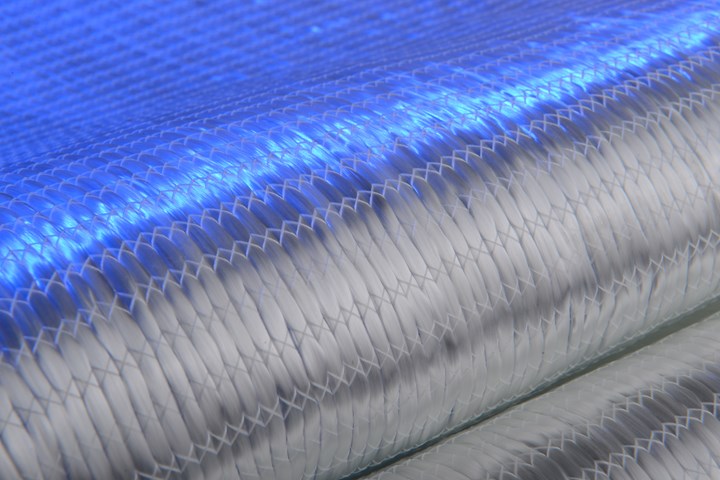

Metyx Composites (Istanbul, Turkey), celebrating its 20th year in the composites industry, recently signed a multi-year material supply agreement with an undisclosed global wind blade supplier. This includes the supply of E-glass and carbon fiber reinforcements, core and fabric kit, consumables and components.

The high-performance technical textiles manufacturer supports wind turbine blade production globally with world-class service and leadership in the composite materials industry. Metyx says its advantage is technical proficiency achieved by focusing on continuous improvements, best practice manufacturing process, high yield production capacity, diversified products and always seeking to exceed safety and environmental goals. As wind blade innovation continues to expand and blades increase in size, further developments in materials and manufacturing processes have been required. Metyx continues to invest in research and production to fulfill these demands for customers.

“We are happy to sign an exciting supply agreement with one of our key customers in the renewables industry,” Metyx Group CEO Mr. Ugur Ustunel, says. “This new contract has a three-year term and will generate a turnover exceeding €100 million for the Metyx Group. Our commitment to renewables remains strong and we look forward to working with our key customers to support them globally.”

Metyx Composites also recently expanded facility space at its Mansia campus.

Related Content

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

-

SRI develops scalable, infiltration-free ceramic matrix composites

Work in two DOE projects is demonstrating C/C-SiC produced in 3-5 days with <5% shrinkage, <10% porosity and 50% the cost of conventional C/C and C/C-SiC.

-

Plant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.