Hexagon Digital Wave signs long-term MAE requalification agreement

Three-year agreement will enable in-situ Type IV COPV assessment for Certarus, a virtual pipeline solutions company, alleviating pain points and ensuring effective requalification.

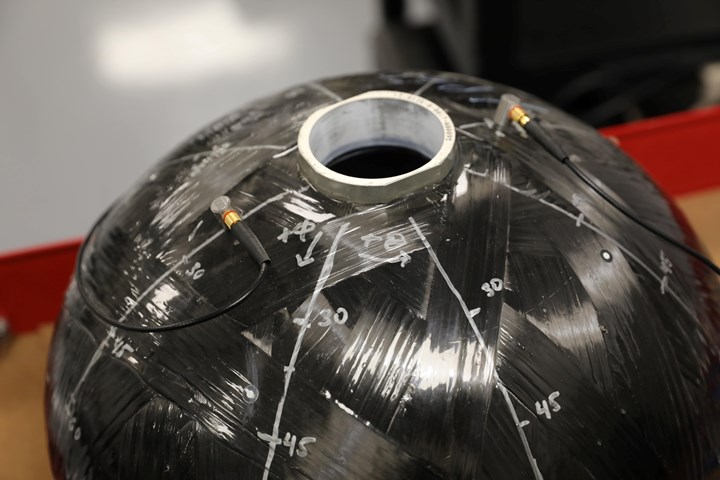

The Type IV cylinder above (MAE sensors attached) is an illustration of those to be tested for Certarus. Photo Credit: Hexagon Digital Wave

Hexagon Digital Wave (Centennial, Colo., U.S.) a business of Hexagon Composites (Alesund, Norway), has signed a long-term agreement with Certarus Ltd. (Alberta, Canada), a provider of turnkey virtual pipeline solutions in North America. Hexagon Digital Wave will perform in-situ modal acoustic emission (MAE) requalification of Type IV composite cylinders used for the transport of compressed natural and renewable natural gas (CNG/RNG). MAE enables the requalification of Type IV cylinders without removal from the trailer, resulting in reduced downtime and operator overhead, all while providing what the company reports is the most effective assessment of composite structural integrity. The long-term agreement has a three-year term and estimated value of $2 million (approx. NOK 21 million).

“This agreement confirms that the future of MAE in the CNG and RNG industry remains strong. It’s also a testament to Certarus’ continued commitment to safety by leveraging best available technology,” Melissa Holler, president of Hexagon Digital Wave, says. “We look forward to supporting Certarus with requalifications of Type IV cylinders and are pleased to be working with such an industry leader to further this adoption in the years to come.”

“Hexagon has been instrumental to the growth of Certarus and we look forward to continuing our relationship through this new agreement,” Curtis Philippon, president and CEO of Certarus, adds. “MAE will ensure that our equipment remains safe and reliable while reducing the downtime and expense typically associated with requalification. We also believe that MAE will support current data, suggesting that the useful life of our assets extends beyond initial industry expectations.”

MAE uses advanced electronics and sensors that capture broadband waveforms to identify whether structural integrity deficiencies are present in composite-overwrappped pressure vessels (COPVs). The use of MAE is a requalification method adopted by the U.S. Department of Transportation (US DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA) and Transport Canada for five-year requalification requirements. Hexagon Digital Wave performs requalification of COPVs under its US DOT special permit 20396. By performing inspections in-situ, the need to vent trailer contents to the atmosphere is eliminated, enabling customers to reduce greenhouse gas (GHG) emissions and meet sustainability goals.

Requalification is set to begin in the fourth quarter of 2022.

Related Content

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.