Heatcon to distribute Hexcel prepregs for UAV/AAM market

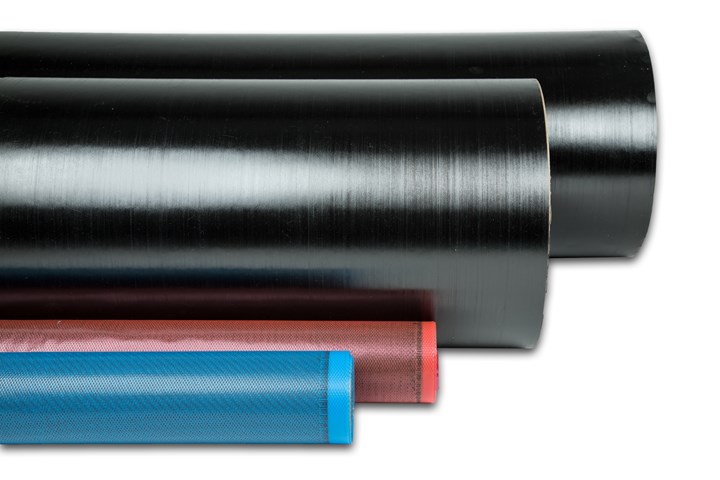

The partnership includes North American distribution of Hexcel carbon fiber prepreg tapes and fabrics to support urban air mobility manufacturing and repair.

In April, Heatcon Composite Systems (Seattle, Wash., U.S.) announced an expanded relationship with Hexcel Corp. (Stamford, Conn., U.S.) for the North American distribution of Hexcel carbon fiber prepreg fabrics and tapes to support the unmanned aerial vehicles (UAV) and advanced air mobility (AAM) industry.

Heatcon, a global manufacturer and supplier of aerospace composite repair equipment and products as well as an official Hexcel distributor, supplies materials such as fiberglass, carbon, peel ply and bagging film to aerospace companies and military providers. The Hexcel partnership focuses on a variety of carbon fiber prepreg products used during the manufacturing and repair process of UAVs and AAMs. According to Heatcon, this partnership will enable Hexcel to increase its presence in the commercial aerospace, space and defense markets.

“The UAV and AAM industry is expanding rapidly, and Heatcon is excited to be a part of this growth,” says Eric Casterline of Heatcon Composite Systems. “Our capabilities allow us to support the industry with readily available inventory in both small and large quantities.”

Heatcon is ISO9001, AS9100D and AS9120B certified. A complete list of Hexcel carbon fiber prepregs available through Heatcon can be found on Heatcon’s website.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

.jpg;width=70;height=70;mode=crop)