Graphene Composites announces approval of Heat Management Systems patent

Thermal management patent describes an engineered, potentially self-powered nanomaterial design that could efficiently transfer thermal energy to better protect vehicle applications.

Graphene Composites (GC, Stockton-on-Tees, U.K.), an advanced and 2D materials engineering company, has announced that its U.K. patent for Heat Management Systems has been approved and is due to grant in April 2024.

Specifically, the patent is for a heat management system that would protect vehicles — including ships and high-speed aircraft — from heat damage. The company’s GC Heat Management System has an engineered, potentially self-powered nanomaterial design that includes a highly efficient heat sink and a thermal transfer fluid.

As thermal energy (e.g., heat) damage is a common problem in many different applications — from struggling to achieve efficient heat dissipation due to inadequate thermal conductivities of materials used, to the efficient but bulky heat management systems that limit their application — there is a need for an improved thermal energy management system which exhibits highly efficient thermal energy transfer.

GC’s patent consists of a protective device comprising of (a) an outer protective cover, with a thermal energy conduction element for transferring thermal energy through at least part of the outer protective cover and (b) an inner assembly located adjacent to the outer protective cover, comprising of a thermal energy transfer device adapted to transfer thermal energy to and/or from the thermal energy conduction element. The thermal conduction element comprises a graphite-like or pyrolytic graphite-like material and the thermal energy transfer device comprises a thermal energy transfer fluid.

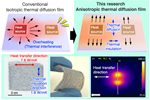

Graphite-like or pyrolytic graphite-like materials are particularly effective at transferring heat and so form effective heat transfer materials — and can be achieved in a single direction due to the anisotropic properties of these materials. This can be particularly effective when combined with a secondary cooling mechanism, such as the thermal energy transfer device.

Thermal energy can be quickly and efficiently transferred between an external environment and the thermal energy transfer device via the thermal conduction element. Efficient heat transfer of these materials and the transfer in one direction enables minimal losses to other parts of the device (and a body which is it protecting) thereby reducing damage to those parts and improving efficiency of the heat transfer. Moreover, these materials also demonstrate optimal stability, strength, wear resistance and fatigue resistance.

GC notes that this enables their use in an application’s outer protective layer as they are less prone to damage under harsh conditions, such as those experienced by aerospace vehicles. Combined with a fluid transfer device, this could provide an efficient way of transferring heat to or away from an area (e.g., the surface or body of the outer protective cover).

GC is at an early technology readiness level (TRL) stage, but intends to explore further development over the course of 2024. Visit the U.K.’s Intellectual Property Office (IPO) for further details about the patent.

Read Next

Nanocomposite films boost heat dissipation in thin electronics

Scientists from Japan develop cellulose nanofiber-carbon fiber composite films with high in-plane heat conductivity to assist in heat dissipation in electronic devices.

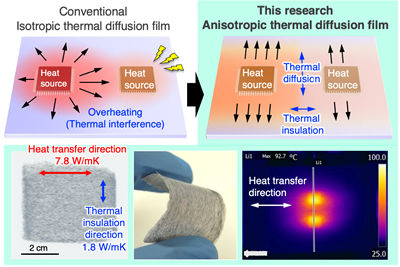

Read MoreMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

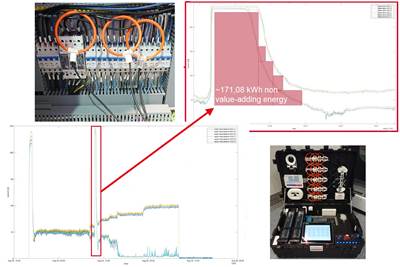

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read More