Cobra supports new production concept for composites-intensive VETAL tailsitter drone

Cost-effective composite tooling and a scaled-up production line target durability, production rate and price parameters for the VETAL’s carbon fiber flying wing airframe.

All photo credit: Cobra International, HG Robotics

Cobra International (Chonburi, Thailand) has expanded its development and manufacturing partnership with Thai unmanned aerial vehicle (UAV) producer HG Robotics (Bangkok). In this latest collaboration, Cobra has supported HG Robotics with the development of an entirely new production concept for the carbon fiber composite flying wing of the “VETAL” vertical take-off and landing (VTOL) drone.

VETAL is a twin rotor, tailsitting drone that HG Robotics has recently launched for large-scale agricultural surveys, as well as general surveillance monitoring. Cobra reports that it has been working with HG Robotics since 2018 to design and produce its composite components.

Having developed VETAL platform’s initial flying shape, HG Robotics had initially produced the first flying prototypes using a more traditional UAV construction technique of thin composite skins, with ribs and frames supporting the hollow structure. However, although these early aircraft performed well in flight, there were concerns that the construction approach used would not be able to meet all the project requirements relating to durability, production rate and price.

Drawing from its decades of experience with close-tolerance molding of EPS foam-cored sandwich components for the watersports market, Cobra proposed a hybrid solution, combining both hollow and cored sections, for the flying wing. The main body of the aircraft comprises a PVC foam sandwich shell with a low-density EPS foam rib which, combined with a fully foam cored tail structure, is said to deliver a complete airframe fractionally lighter than the customer’s challenging target.

In addition to an impressive cycle time reduction, the new build method also improved the impact resistance and overall durability of the VETAL platform, a key benefit for industrial users who need survey drones with minimum maintenance.

To reduce weight, a combination of carbon fiber stitched biaxial fabrics and unidirectional (UD) reinforcements are used wherever possible, Cobra says, with additional glass fiber-reinforced laminate sections being employed where radio transparency or insulation from metallic parts is required.

The Cobra production engineers have also been able to incorporate glass fiber reinforcements and mounting points for the VETAL’s propulsion system and other ancillary equipment into the molding process, minimizing the additional processing steps in the assembly and finishing stages.

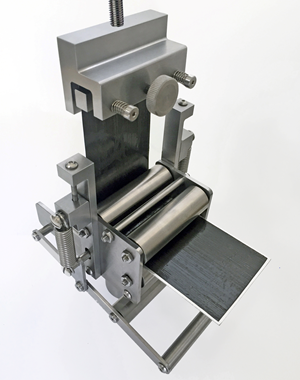

Currently, cost-effective composite tooling has been produced for the first Cobra-built VETAL airframes, enabling a rapid start-up to the series production, while still providing the possibility for incremental design changes before switching to CNC-machined aluminum tooling for high-rate production in the future. With process parameters defined in line with the company’s lean manufacturing principles, Cobra has prepared a production line that can scale up quickly. HG Robotics has also successfully developed an extensive client base for its previous multi-rotor drones and Cobra expects to see considerable demand for the new VETAL platform for larger scale survey applications.

“We are pleased to be strengthening our relationship with HG Robotics and working together on the VETAL project,” says Sila Sertsorn, technical director, Cobra International. “It is a great example of how Cobra can develop durable, reliable and affordable composite components and manufacture on a mass production scale. Our customers are exceptional product designers, and we provide the complimentary skills to incorporate the most efficient composite materials and processes.”

Related Content

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreComposite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreProtecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Cobra International supports composite electric hydrofoil board evolution

Cobra continues to deliver materials, production process support, as well as manufacture Fliteboard’s carbon fiber Fliteboard Series 2 surfboards.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)