CNT-enhanced carbon fiber strengthens mountain bike team's race wheels

NAWA’s vertically aligned carbon nanotube technology enhances shock resistance, increases strength for Santa Cruz team’s mountain bike wheels.

Nanomaterial technology specialist NAWA (Dayton, Ohio, U.S.) announced on July 1 that its nanotechnology-enhanced carbon fiber materials will be featured in composite racing wheels by the Santa Cruz Syndicate downhill mountain bike team. NAWA has been named an official Santa Cruz Syndicate partner in 2021, and this is the fourth competitive season that Santa Cruz has employed wheels using NAWA’s materials.

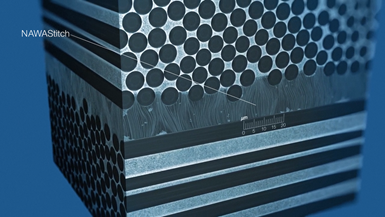

The competition-only Reserve rims feature NAWA’s materials concept, NAWAStitch, which employs carbon nanotube (CNT) technology to enable more resistance to strike damage and higher strength than conventional carbon fiber. According to NAWA, NAWAStitch has the potential to reduce the number of wheel failures experienced by the team over a competitive season by 80%.

NAWA’s technology works by integrating vertically-aligned carbon nanotubes (VACNT), which are manufactured by NAWA using a patented process, between the layers of a composite structure to add superior strength. For the Reserve wheels, the NAWAStitch material consists of a thin film containing trillions of VACNT, arranged perpendicular to the carbon fiber layers. Acting as “nano-velcro,” the tubes reinforce the interface between the layers, which is the weakest area of the part.

NAWASTICH also improves strike damage resistance by eliminating the probability that a crack will occur in the interface. In addition, in its own tests, NAWA has found that NAWAStitch-reinforced carbon fiber composites have shear strength increased by a factor of 100 and shock resistance by a factor of 10.

Nic McCrae, senior composites engineer at Santa Cruz, says, “In downhill racing, the wheels suffer hard, repeated impacts with rocks and roots. Failures occur when the tire bottoms out and the rim bead cracks. NAWAStitch has made the wheels much stronger, we believe by increasing the buckling resistance of the inner surface of the rims during these high compressions. What’s more, NAWAStitch does not affect the way wheels respond to the riders’ inputs — they behave completely consistently, which allows them to push harder and go faster. Through a combination of our own profile design, precise wheel-building and the introduction of NAWAStitch, our Reserve wheels are without doubt the strongest rims on the circuit.”

Pascal Boulanger, founder, chairman of the board and chief technology officer of NAWA Technologies, says, “NAWAStitch brings game-changing improvements in the core strength of composite materials and we are very proud to see its considerable performance benefits coming to the fore in the team’s Reserve race wheels. We look forward to working with Santa Cruz Syndicate and wish them every success in competition.”

Development of multifunctional ultra-strong composites, such as NAWAStitch, is led by NAWA’s NAWA America division, based in Dayton, Ohio and created in 2020 when NAWA acquired N12 Technologies. In addition to supporting the Santa Cruz Syndicate in the development of its competition-only Reserve wheels, NAWA America is finalizing development of NAWAStitch for use in volume industrial applications, and expects to ramp up to full production by next year. In the short term, first markets will be sporting equipment, consumer products and luxury goods, while longer-term prospects are in automotive and aerospace. Combined with its home facility in France, NAWA Technologies will offer a wider portfolio of solutions to its customers, combining lighter, stronger and smarter composites and energy storage.

Related Content

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

NAWA Technologies develops U.S. subsidiary to extend VACNT application scope

NAWA America’s immediate focus is to bring NAWAStitch to mass market, a thin film containing trillions of VACNT arranged perpendicular to the carbon fiber layers to reinforce the weakest part of a composite.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)