AniForm, Moldex3D develop interface tool for more accurate RTM prediction analysis

Interface enables users to consider forming-induced fiber reorientation in the RTM simulation model for a more accurate representation of the flow domain.

All photo credit: AniForm, Moldex3D

AniForm Engineering (Enschede, Netherlands), an advanced simulation tool that predicts the formability of composite laminates, is collaborating with Moldex3D (St. Zhubei City, Taiwan) to enable users to run more accurate resin transfer molding (RTM) analyses. With this new interface, workflow has been improved to smoothly import the fiber reorientation data (recorded as an ASCII file) from AniForm Suite and run the RTM simulation with Moldex3D’s simulation tools. Additionly, input accuracy for the RTM model has been optimized and RTM simulation results made more accurate.

“AniForm strives to deliver a software tool that enables engineers to focus on the analysis of a prediction, rather than spending too much time on modeling and data transfer between various simulation tools,” says Sebastiaan Haanappel, managing director at AniForm. “Moldex3D is a renowned partner in the industry, so we were thrilled to cooperate with them. We were very happy with this collaborative effort, which led to a seamless interface between our tools.”

When coming up with the solution, both AniForm and Moldex3D focused on targeting the following challenges:

- Lack of a seamless workflow between the different simulation tools;

- The fiber orientations in a fabric change significantly during forming;

- Fabric shear and fiber reorientation locally affects the magnitude and orientation of the fabric’s permeability property.

To address these, a case study was performed, with the main objective to compare the different results between two models; one that directly assigned an assumed orthogonal fabric orientation, and one that considered the fabric orientation result from an AniForm forming prediction. The goal was to see how different inputs can have a significant impact on the resin infusion simulation results.

First, AniForm’s team generated a simulation of a woven fabric forming that was then used as an input in Moldex3D software for the fabric orientation. The fabric simulation was exported as an ASCII file from AniForm and imported in Moldex3D to run the RTM simulation.

Then, the part was created. A laminate consisting of five fabric layers with a [(0/90)]5 layup was formed into a mold cavity, which represents the final part shape. Subsequently, the mold itself was heated and injected with resin, with a final part released after curing. This part was referred to as the Formed Woven Fabric (Fig. 2).

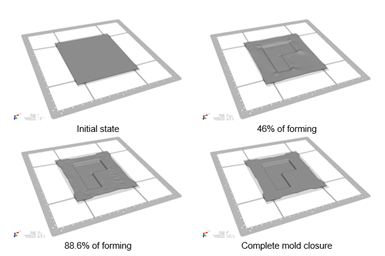

Fig. 3. AniForm forming predictions at various instances.

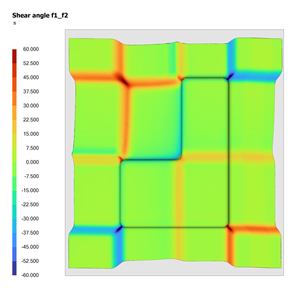

To take into consideration the forming induced fabric distortions in a subsequent infusion simulation in Moldex3D, a composite forming simulation in AniForm was performed. Fig. 3 shows the predicted laminate deformations at various instances during the forming. These deformations led to the resulting in-plane shear distribution and related fiber re-orientation at complete mold closure in the final step as shown in Fig 4.

Fig. 4. Shear angle distribution predicted by AniForm.

Two infusions model configurations were created in Moldex3D (see Fig. 5). The first model assumes the fabric still to be orthogonal, namely 0º and 90º in every part (light blue: 0º, dark blue: 90º). However, Moldex3D and AniForm note that, in reality, an orthogonal fiber orientation will not be present since the forming leads to in-plane fabric deformation, meaning the fabric orientation will no longer be 0º and 90 in every part. Therefore, the second model considers the forming results from AniForm, using the forming induced fiber-reorientation. Because the fiber reorientation affects permeability (indicated in Fig. 6), Moldex3D and AniForm believe the second model to result in a more accurate representation.

Fig. 5. Fabric orientation.

Fig. 6. Flow front.

Thus, the case study concluded that the developed interface, improving the estimation of the flow progression over time, enables engineers to better anticipate changes in the process configuration and production cycle durations, as well as a higher degree of confidence when analyzing and interpreting the results.

“We are delighted to cooperate with AniForm, which is undoubtedly a remarkable player in our industry,” says Dannick Teng, managing director at Moldex3D. “This is the first step of Moldex3D and AniForm’s collaboration, and we are both looking forward to further integration soon.”

For more information, please contact support.eu@moldex3d.com or info@aniform.com

Related Content

Spanish startup to ramp up production of “recyclable” EV prototype

Liux’s BIG electric vehicle features multiple structural components manufactured via RTM from flax fabric and a thermoset resin said to enable the entire component to be recycled and reused again.

Read MoreKAI demonstrates thermoplastic and infused structures for future airframes

Korea Aerospace Industries advances its expertise through a welded TPC fuselage section and resin-infused wing skin module and torsion box demonstrators.

Read MoreLIFT to lead new "Critical Materials Processing" program on ceramics, CMC

Multifaceted project aims to accelerate development and scale-up of ultra-high temperature material technologies including ceramic matrix composites (CMC) and carbon fiber as a precursor in CMC preforms.

Read MoreBucci Composites expands automotive production capabilities with facility addition, new high-ton presses

CW Top Shops recipient Bucci Composites shares an update on its facility expansion, automotive composites applications, sustainability, education initiatives and more.

Read MoreRead Next

Thermoplastic composite materials and processing interactions

Selection of product material formats and their interactions with various process methods heavily influence a final TPC part’s properties and fabrication options.

Read MoreComposite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More