Aditya Birla Chemicals acquires recyclable thermoset technology from Connora Technologies

The acquisition of Connora's Recyclamine technology enables end-of-life recyclability and zero-waste manufacturing to global epoxy customers.

Aditya Birla Chemicals Thailand Limited today announced the acquisition of Connora Technologies’ Recyclamine technology. Connora Technologies is the pioneer of recyclable epoxy resin technology, based on a novel proprietary polyamine synthesis platform called Recyclamine. Recyclable thermoset technology was recognized as one of the Top 10 emerging technologies in 2015 by the World Economic Forum. Aditya Birla Chemicals Limited Thailand, a parent company of CTP Advanced Materials (Germany) and owner of Epotec and CeTePox Brands, is one of the leading manufacturers of epoxy resins and curing agents globally. Aditya Birla Chemicals, part of the $48.3 billion global conglomerate Aditya Birla Group, and Connora Technologies, have been collaborating since 2016 in a Joint Development Agreement to scale-up the manufacturing of Connora’s recyclable epoxy thermoset technology.

Kalyan Ram Madabhushi, CEO Chemicals, believes that the acquisition of Recyclamine technology is a natural next step for Aditya Birla Chemicals, as it constantly strives to bring innovative and sustainable advanced polymer solutions to its customers. This technology not only enables incremental value creation through zero-waste manufacturing to customers, but also uniquely offers end-of-life recyclability options.

Pradip Kumar Dubey, President of Aditya Birla Chemicals Epoxy Division, says, “This acquisition reaffirms our commitment to being an Advanced materials player, offering sustainable and unique solutions that matter to our customers and society in general. Recyclamine is revolutionary for the epoxy and composites industries, as it will enable the manufacturing of recyclable products. Before this innovation, it was just not possible to do so.”

Dr. Stefan Pastine, Co-Founder and CTO of Connora Technologies explains, “As a chemical technology start-up company, we always knew that forming a close partnership with a world-class chemical company would be required for our technology to get to scale. This acquisition is the culmination of a multi-year relationship and the result of the dedication and unwavering commitment to the vision of the Recyclamine technology, from both ABCL and Connora.”

Connora’s co-founder and CEO, Dr. Rey Banatao, adds, “The investment in Connora over the years from a large and well-respected global manufacturing partner such as Aditya Birla Chemicals, has been invaluable to the commercial development of recyclable thermoset technology. Due to their decades of expertise in scale-up manufacturing and sales of epoxy resins, on a global scale, I expect that over the next decade, Recyclamine technology will be commonplace in many epoxy-based composite products, from sporting goods to automobile parts and windmill blades.”

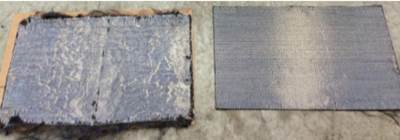

Polyamines are used in diverse applications ranging from fuel additives and lubricants, to cross-linkers in high-performance thermoset plastics, such as epoxy resin or polyurethanes. Epoxy thermosets are traditionally the material of choice in adhesives, coatings, and light-weighting in the aerospace, automotive, windmill, and sporting goods industries. Connora’s Recyclamine synthesis platform provides a modular and rapid chemistry approach for making new polyamine molecules. A unique and patented feature of Recyclamine is the ability to create cured thermoset resins that can, on command, be recycled into a reusable thermoplastic, thus enabling ‘end-of-life’ recycling and ‘zero-waste manufacturing’ in the thermoset composites industry.

The efficient recycling of composite materials should have a positive impact on the automotive and aerospace industries, where the trend to make lighter, stronger, and more energy-efficient vehicles is driving growth in the use of carbon fibre composite materials. Composites industry reports state that the manufacturing of composites today generates 5-40% of raw inputs as waste materials, for which there are few options in recycling or reuse. Making composites more recyclable through the use of Recyclamine should help reduce the overall cost of manufacturing of composite products, by re-integrating composite waste and reducing landfill costs.

About Aditya Birla Chemicals

Aditya Birla Chemicals is a leading manufacturer of bulk and specialty chemicals and viscose filament yarn. The business is spread across multiple manufacturing locations in four countries – India, Thailand, Germany and China. The business is creating a strong footprint in the chemicals industry – it is a market leader in the chlor-alkali segment in India; at number two position in viscose filament yarn and is the third-largest manufacturer in the world in sulphites.

Aditya Birla Chemicals manufactures epoxy resins in liquid, solid, solutions, blends and multifunctional forms, and markets these under the Epotec brand. These high-quality epoxies find wide application in the automotive, construction, heavy engineering, transport, electronics, food and beverage packing, coatings, composites, adhesives, aviation, aerospace and wind energy industries.

The Chemicals business has 14 manufacturing sites – seven in India, five in Thailand, one in Germany and one in China. These operations are handled through two companies in India Grasim Industries and Tanfac; two companies in Thailand – Aditya Birla Chemicals (Thailand) and Thai Peroxide Company and one company in Germany – Aditya Birla Chemicals (Europe) Gmbh. In China, the business operates through Aditya Birla Grasun Chemicals (Fangchenggang).

For more information, visit:

http://www.adityabirlachemicals.com/products/epoxy_resins/epoxy_resins_overview.html

About Connora Technologies, Inc.

Based in Silicon Valley, CA. USA, Connora Technologies is a venture backed, next-generation chemical company with expertise in design of performance thermoset materials. Their revolutionary Recyclamine® polymer technology forms the basis for creating a new market around transformable and reusable thermoset plastics. Recylamines® balance performance, cost, manufacturability, and recyclability and for a new class of diverse performance polymers. Upon the acquisition of Recyclamine, Connora will now spin-out another company based on its Smart Dielectric® films, in order to address cost and performance limitations in electronic materials, ultimately enabling more powerful mobile electronic devices. Connora was supported by NSF SBIR Award #1632433, and major investors include Samsung Ventures, Entropy Research Labs, the Chemical Angel Network, and individual angel investors.

For more information, visit http://www.connoratech.com

Email: info@connoratech.com

Related Content

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read MoreRead Next

Recyclable epoxy proven in HP-RTM

Recyclamine hardener performs well in global processing trials and cradle-to-cradle recycling demo.

Read MoreComposites – the next big recycling business?

Reps from the composites industry recently spoke at The Plastics Recycling Conference about the potential opportunities in this sector.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More