3D-printed continuous fiber dental reinforcements enter clinical trial

Hi-Fiber, partnering with Malo Clinic, is a dental reinforcement brand producing continuous glass fiber dental structures using Moi Composites’ CFM technology for a natural smile.

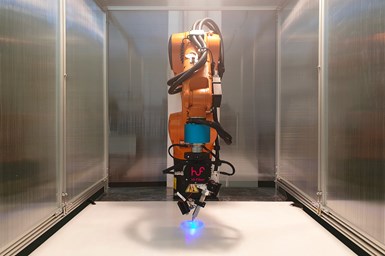

Photo Credit: Hi-Fiber.

On Nov. 1, dental reinforcement brand Hi-Fiber (Milan, Italy) has established a partnership agreement with Malo Clinic (Lisbon, Portugal) a company known for its oral rehabilitation and dental aesthetics. The partnership includes clinical trial cases using Hi-Fiber’s metal-free dental reinforcement structures designed and 3D printed from advanced materials and the company’s patented continuous fiber manufacturing (CFM) technology.

CFM, which 3D prints continuous fiber thermoset composites, comes from parent company Moi Composites srl (Milan, Italy). CFM incorporates a single strand of continuous fiber composite material, proprietary software and robotic process to smartly design, 3D print and rapidly cure fibers precisely where needed, reportedly eliminating production scrap, waste of metals or expensive material and saving time and resources.

“It is the meeting of two excellences,” describes Michele Tonizzo, CTO and co-founder of Moi Composites “Malo Clinic represents excellence in dentistry. Our technological solution is the missing part of their protocol, and the missing link to create the perfect smile. Collaborating with Malo Clinic was something we were aiming for from the beginning of Hi-Fiber’s development. It’s inspiring.”

Hi-Fiber was born from the needs of a dental technician and a dentist, Gianluca Brandolini and Andrea Nicali, and the technology patented by Moi Composites. The problem originated from the impossibility of finding an implantological solution with a natural biomechanical behavior and resistance to high loads without compromising aesthetics.

According to Brandolini, the use of continuous glass fiber for implants — fully transparent with an elastic modulus similar to the cortical bone and a strength higher than most metals — was too difficult to model manually, and the results were unpredictable and unsatisfying. “We needed a machine that could 3D print in continuous fiber,” says Brandolini.

CFM robot printing the dental reinforcements.

It was by chance that Andrea Nicali learned of Moi Composites, and got in touch with its team. Since then, Hi-Fiber has had five years of analysis, refinements and clinical cases, becoming a widely adopted solution in Italy for the reinforcement of fixed and removable prosthesis, overdentures, maryland bridges and orthodontic splints, with several more developments to come. Similarly, Moi Dental, a division of Moi Composites, has entered into partnerships with leading companies in the sector such as VITA Zahnfabrik, ETK/Lyra and 3Shape and its production process is certified under UNI EN ISO 13485.

According to Hi-Fiber, the advantages of its solutions extend to the final customer in terms of aesthetics and resistance to stress. Hi-Fiber, once implemented inside the prosthesis, unlike alternatives such as metal and zirconia, is translucent, allowing light to pass through and giving the patient a natural smile.

Furthermore, obtaining a monolithic prosthesis allows to distribute the stresses evenly between the supports, reaching an unprecedented resistance to weight (less than 1 gram for Hi-Fiber), which translates into a significant reduction of fractures and a smaller probability of implant failures.

These biomechanical characteristics are also reported to ensure a longer life of the prosthesis, without the need to return to the dentist for further repairs. Finally, AM technology makes the entire production process free of waste.

Hi-Fiber notes that, with its reliable bio-medical applications, it is ready to partner worldwide to make Hi-Fiber the gold standard for high-quality dental reinforcements.

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)