PEKK

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

WatchMarkforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

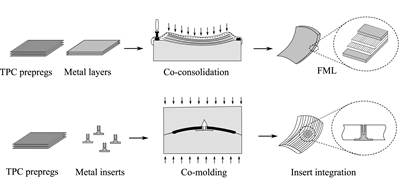

Read MoreHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreStratasys collaborates with Lockheed to qualify composite materials for space, aviation end-use parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties.

Read MoreSolvay completes South Carolina facility installation, adds to U.S. thermoplastic composite capacity

Facility development is fueled by increasing energy, aerospace and automotive demand, and will manufacture UD PVDF, PPS and PEEK tapes.

Read MoreCAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read More9T Labs assesses AM for medical, aerospace applications

9T Labs conducts two studies to assess the viability of its Red Series additive manufacturing system to manufacture a carbon fiber/PEKK aerospace hinge and a surgical tool.

Read MoreTPRC publication studies the effects of grit-blasting on titanium-thermoplastic composite joints

Researcher Vanessa Marinosci studies the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints.

Read MoreOhio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

Read More

.jpg;maxWidth=300;quality=90)