Carbon fiber composite hydrofoils to enable “world’s fastest” electric ferry

The Candela P-12 Shuttle, set to launch in Stockholm, Sweden, in 2023, will incorporate lightweight composites and automated manufacturing to combine speed, passenger comfort and energy efficiency.

Read MoreLockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreCAMX 2022 exhibit preview: UAMMI

The Utah Advanced Materials and Manufacturing Initiative (UAMMI) brings together academic and industry partners to promote composites industry growth in the state of Utah.

Read MoreDustless, mobile solution for on-site wind turbine blade repurposing

Denmark-based Isodan Engineering ApS translated its expertise in mobile, shipping container-based newspaper recycling systems to solve a need for breaking down wind turbine blades on-site for reuse.

Read MoreCollaborators awarded NIST funding to develop in-space manufacturing roadmap

Purdue, the University of New Hampshire and the University of Alabama will work with NASA to develop a roadmap for in-space manufacturing.

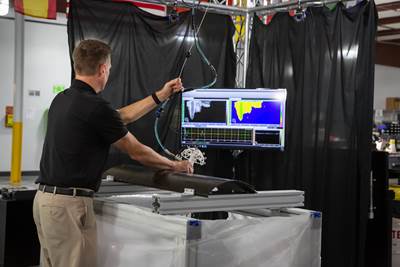

Read MoreCAMX 2022 exhibit preview: Innerspec Technologies

Taurus and Camus 3D ultrasonic inspection systems provide automated and semi-automated solutions for composite aerospace components.

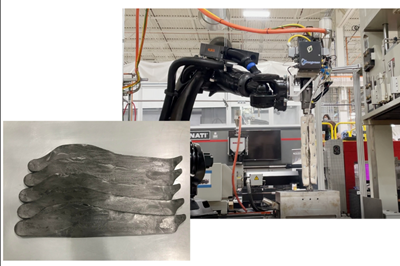

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

WatchVestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

WatchEx-Core Technologies' Ex-Core 2.0 system features intelligent self-heated tooling, custom-mixed core

Debuted at JEC World 2022, Ex-Core 2.0 is said to slash production costs compared to conventional prepreg sandwich processes and produce lighter, stronger parts.

WatchAIR ONE two-seater eVTOL achieves first hover tests

AIR’s all-electric personal air mobility vehicle, which incorporates composites in structural and aesthetic components, is expected to deliver its first vehicles by 2024.

WatchOverair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

WatchHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read More.jpg;maxWidth=250;quality=70)