Virtual process chain + online process monitoring = first-time-right manufacturing

Co-authors Dr. Michael Bruyneel, Marc Attar and Dr. Christian Brauner (Siemens PLM Software, Liège, Belgium) illustrate the benefits of manufacturing simulation software in virtual trials of molding processes, using resin transfer molding as a reference.

The big challenge of composite design is to develop a part that will satisfy geometric tolerances and performance requirements (e.g., weight, thermal and mechanical behaviors). Today, even if sizing of composite structures can rely on predictive models and accurate large-scale, nonlinear analyses — including damage as demonstrated in industrial applications1,2 — composites fabrication is still considered an art. However, manufacturing simulation tools can be used to guide manufacturing process development. The benefits of this approach are discussed here using resin transfer molding (RTM) as a reference.

RTM process simulation

RTM is used in the aerospace industry and also as a solution for process automation in the automotive sector because this closed-molding process offers possibly fast cure cycles and good mechanical properties in the resulting part: Bonded or stitched layers of dry fibers (the preform) are laid in the mold; the mold is closed; a (typically) thermoset resin is injected and cure is accelerated through a temperature increase as consolidation pressure is applied. The cured part and mold are cooled and the part is demolded.

The manufacturing process, however, induces defects in the composite part. Residual stresses develop during cure and usually lead to geometric defects, such as spring-in (closing angle of corners) and warp (distortion of initially flat surfaces). Amplified by the anisotropy and the inhomogeneity of the layup, these unwanted effects come from the thermal strains and chemical shrinkage during cure, caused by the temperature change and the resin’s phase transition from liquid to rubbery and, finally, to glassy state.

Of the principal sources of process-induced stresses and distortions, high cure temperature is the greatest. The second is chemically induced resin shrinkage. The manufacturing process and resulting part quality are driven by parameters such as mold geometry and material and process time and temperature (i.e., cure cycle). Moreover, where warpage is concerned, factors that can influence the symmetry conditions of the layup are critical. Some of these factors can be related to the preforming stage (e.g., fiber-angle and ply-contour errors, undulation, gaps and overlaps), as well as to curing-control or resin-flow problems. Developing the manufacturing strategy and specifications to address all of these is an iterative process: Process parameters are tuned and mold geometry is modified, typically by trial-and-error. This is time-consuming and costly because it requires the iterative production of a succession of different physical molds and parts.

Today’s manufacturing process simulation tools, however, have reached a high degree of maturity. State-of-the-art algorithms, such as those proposed in Fibersim, are used to develop efficient draping strategies for unidirectional plies and fabrics and help the user understand the behavior of the material laid on the mold. A bi-directional link between CAD and CAE programs enables flawless information exchanges between designer and analyst, which speeds and improves the interactions between the different disciplines, such as design, sizing and manufacturing process analyses. In addition to the preforming simulations, accurate cure kinetics models now can be comprehensively implemented in the finite element package (e.g., LMS Samtech Samcef), which can be used to conduct thermo-chemical-mechanical analyses.

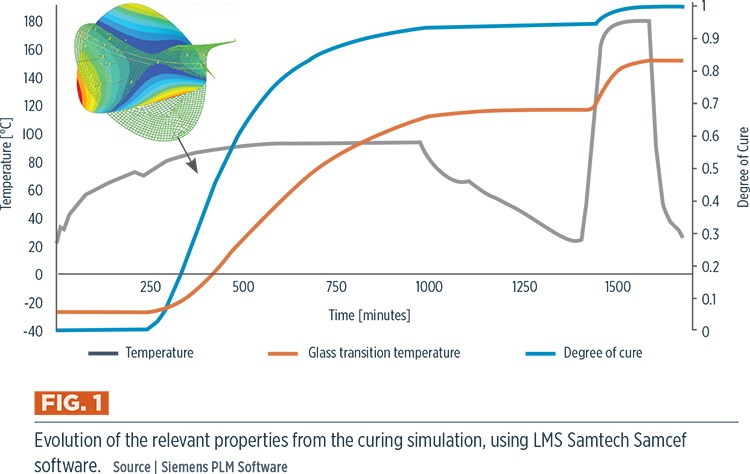

Typically, thermal boundary conditions for the RTM simulation are defined in the finite element model of the composite part, knowing that to be more accurate, a high-fidelity model of the mold also must be developed. The thermo-mechanical analysis — taking into account the exothermic aspect of cure — provides the distribution and evolution of the temperature, the glass transition temperature and the degree of cure in the part during the whole cure cycle. The mechanical analysis is then run with this information to get the effect of the phase transformation of the resin on the resulting viscoelastic properties of the matrix.

The objective is to obtain the equivalent properties of the plies and predict the residual stresses during the process simulation, together with the final shape distortion. Finally, a structural analysis can be conducted to evaluate the mechanical performance of the composite part. These advanced thermo-chemical-mechanical analyses can be performed with cure kinetics model parameters determined from well-identified, specific tests, and a good agreement has been observed between the obtained numerical solution and experimental results.3,4 Further, a consistent simulation chain can support the development of the manufacturing process by evaluating the sensitivity of the part quality to the process parameters. Then, the geometric tolerance requirements of the part can be reached by applying mold compensation to the virtual prototype. This consists of modifying the geometry of the parameterized mold model, using either mathematical optimization algorithms or the opposite of the nodal displacements computed during the distortion analysis, both iterative processes.

Analyzing the “as-built” configuration

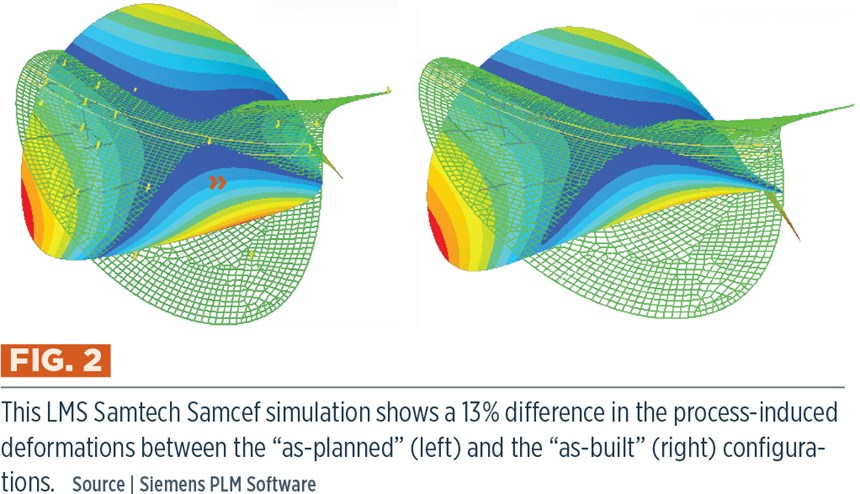

Relying on simulation is a great advantage for the development of the manufacturing process. It can be used to develop the right mold geometry and determine the range of process parameters that will control the shape distortion and, finally, provide a part that satisfies geometric tolerances. However, the world is not perfect, and analyzing the structural performances on the “as-planned” (sometimes called “as-designed”) configuration might be inadequate. Given the nature of composites manufacturing processes, many variations are possible, and it is essential to analyze the “as-built” (sometimes called “as-manufactured”) configuration as well, in order to study the effects of deviation from the “as-planned” configuration in an early stage of the development process. This idea was developed in the ECOMISE project5, and the virtual process chain is combined with an online monitoring system for preforming, injection and curing, providing a feedback loop from the real world to the virtual prototype. One of the important feedback concerns includes the deviations and variations during the draping or preforming of the textile plies. These include incorrect ply positioning, unexpected gaps, overlaps, fiber deviation, thickness variations or foreign objects in the mold. The effect of these variations might be critical if they influence the infusion behavior and create asymmetrical conditions that induce shape distortions.

These defects may be detected by image-analysis devices during preforming or by adapted sensor strategies during the injection and curing phases. This information is reported to the model. Then the effect of the defects can be analyzed along with the virtual prototype, their impact on its structural performance estimated, and adjustments for an efficient manufacturing process can be proposed. When a doubly curved composite part is manufactured, for example, the goal is to identify the error in the ply positioning with the image analysis measurement system. This information is then reported to the virtual model, where the draping simulation is carried out, taking into account the “as-positioned” ply (Fig. 1, p. 10). The curing is simulated, and the resulting shape distortion is evaluated and compared to the “as-planned” configuration (Fig. 2, p. 12). More information and results are available from Brauner, et al.6 This interaction between real-world and simulation, together with the feedback loop for the manufacturing process adjustment, is an essential ingredient for reducing production time and cost, as well as related material and energy consumptions.

References

1 Bruyneel, M., Naito, T., Urushiyama, Y., McDougall, S. (2015). “Predictive simulations of damage propagation in laminated composite materials and structures with LMS Samtech Samcef,” SAE technical paper 2015-01-0697.

2 Bruyneel, M., Delsemme, J.P., Jetteur, Ph., Germain, F., Boudjemaa, N. (2014). “Damage modelling of composites: validation of an inter-laminar damage model at the element level in an industrial application,” JEC Composites Magazine, N°90, June-July 2014.

3 Brauner, C. (2014). “Analysis of process-induced distortions and residual stresses of composite structures”, Ph.D Thesis, FIBRE, Faser Institute, Bremen University, Germany.

4 Brauner, C., Bauer, S., Herrmann, A.S. (2015). “Analyzing process-induced deformation and stresses using a simulated manufacturing process for composite multi-spar flaps,” Journal of Composite Materials, 49, pp. 387-402.

5 ECOMISE project. “Enabling next generation composite manufacturing by in-situ structural evaluation and process adjustment” (www.ecomise.eu).

6 Brauner, C., Miene A., Bruyneel, M., Pascon, F., Herrmann, A.S. (2015). “Advances in virtual process chain and connection with on-line monitoring methods for first time right manufacturing of thermoset laminated composites,” NAFEMS World Congress, June 21-24, 2015, San Diego, US.

Related Content

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)