Solid Modeling Software Provides Seamless Integration Between Programs

When the company was looking for seamless integration with its CAD/CAM and solid modeling software and the ability to jump back and forth between programs, Omega looked no further than PowerSHAPE from Delcam (HQ Birmingham, UK; subsidiary offices Windsor, ON; and Salt Lake City, UT) to fit the bill.

Omega Tool Corp. (Windsor, ON) is a producer of high-quality, plastic injection, compression, RIM and die cast molds primarily for the automotive industry. These molds are used to produce both automotive and non-automotive plastic and die cast parts. When the company was looking for seamless integration with its CAD/CAM and solid modeling software and the ability to jump back and forth between programs, Omega looked no further than PowerSHAPE from Delcam (HQ Birmingham, UK; subsidiary offices Windsor, ON; and Salt Lake City, UT) to fit the bill.

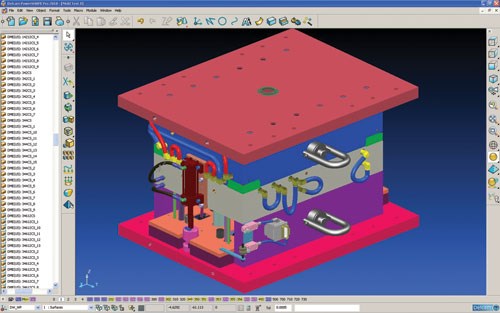

The automotive molds Omega Tool manufactures consist of door panels, grills, bumper fascias, steering wheels, instrument panels, fenders, body side moldings, garnish moldings, body panels, mirror assemblies, and other interior and exterior vehicle trim systems. Non-automotive molds encompass plumbing accessories, industrial parts, pipe fittings, pails and other consumer hardware accessories.

According to Calvin Matte, Advance Design Engineer at Omega Tool, what intrigued him most about Delcam software is that the company does an excellent job of ensuring that the products it sells to its customers work. “That in itself shows me that they are innovators—they just didn’t go along with the norm,” Matte states. “We build very large tooling, up to 110,000 pounds, so mistakes can cost our customers—and Omega—a lot of money.”

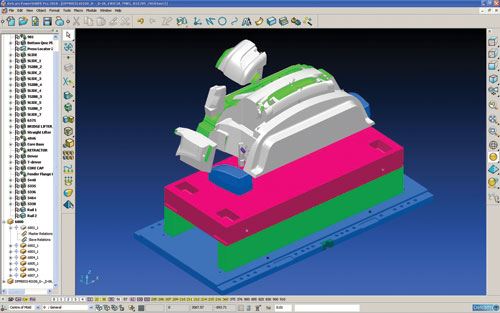

PowerSHAPE software provides modeling for manufacturing, electrode design, and mold and toolmaking. According to Delcam Product Specialist John Hunwick, PowerSHAPE is versatile and easy-to-use. “PowerSHAPE’s unique combination of modeling tools allows the user to create detailed, accurate 3-D models of even the most complex parts simply and efficiently,” he says.

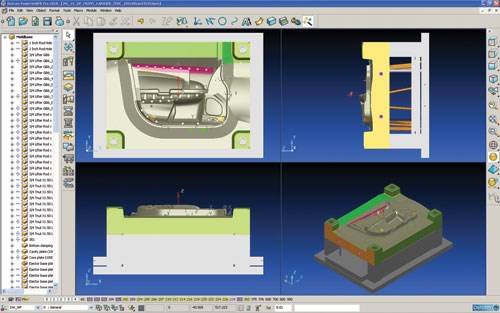

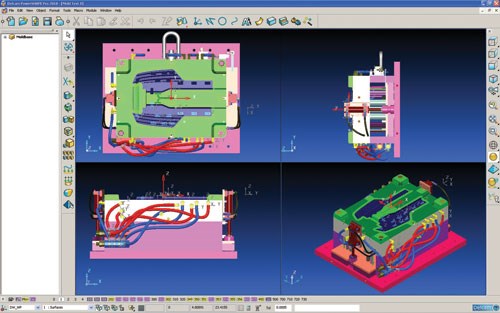

Complex, 3-D parts can be designed using any combination of surfaces, solids or triangles, Hunwick points out. And, the software can make sense of imported data no matter which CAD system created it, which is important to Matte, who notes that using PowerSHAPE has not only simplified Omega Tool’s manufacturing process, but also has reduced leadtimes.

Hunwick explains that PowerSHAPE simplifies surface modeling with its unique Smart Surfacer feature. “Simply select the sketches and PowerSHAPE automatically creates a surface,” he comments. “Easy-to-use editing tools let the user modify surfaces interactively to achieve the perfect shape, no matter how complex.”

Omega owns PowerSHAPE products—and all of the Delcam products—and has actually been BETA testing for almost 20 years for them. Matte notes that seamless integration is the top selling point for him. “I need to know everything works well with each other,” he explains. “Now I can go to a meeting with just my laptop and PowerSHAPE and load a KIA model. I can go to General Motors and load a Unigraphics model. We also do some work for Whirlpool. I can go there and load a Pro/E file. I don’t have to spend all of my time making sure all of the proper software is on my laptop—will it come in, won’t it come in? It is just done seamlessly.”

Matte also says PowerSHAPE is very simple to use. “PowerSHAPE and Parasolid work together seamlessly,” he explains. “For example, say I want to add a product to my screen that is already done by General Motors. It may look like a simple part but there are probably over 13000 surface models. That’s a lot of data. But I can just go there and say to my laptop, ‘UG part file,’ select it and then say ‘Open.’ With PowerSHAPE and the new Parasolid kernel it’s direct from Unigraphics right into PowerSHAPE.

“If I go to a CAD software that is running another Parasolids kernel I can share it with them and they will get the same look, the same solid that I have,” Matte continues. “That is very important. I can now share it . I can send it down to the shop floor, I can send it to PowerMILL . Everything will be seamless. PowerSHAPE, PowerMILL and PSexchange are individuals programs from Delcam that we can integrate together and they go together seamlessly. To me, that is the power you are going to find with this product that you are not going to get with other CAD/CAM products on the market.”

For more information:

Delcam PowerSHAPE / (877) DELCAM 1

powershape.com

Omega Tool Corp. / (519) 737-1201

omegatoolcorp.com

Related Content

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read MoreComposites end markets: Automotive (2025)

Composites manufacturing intelligence drives circular economy solutions as automotive industry balances technical demands with sustainability mandates.

Read MoreRead Next

Composite trends gaining industrial traction for 2026

Startups & Investors topics over the last year show the industry is rapidly gaining maturity while benefiting from macro-trends in circularity, AI and TPC and high-rate manufacturing, all potential gains for investors.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read MoreFrom PMCs to sandwich composites: Tracing the path of test method standardization

Over the decades, progression of PMC and sandwich composite test method development and standardization has been shaped by the requirements of the composites industry.

Read More