In Part I, “Rediscovering the benefits of prepregs in composites manufacturing,” I observed how efficiency and quality played an important role in understanding the value that towpreg and prepreg can bring to the manufacturing environment. In this second and final part of the series, I will explore how prepregs improve performance and safety, sum up towpreg and prepreg benefits and assess the increased profitability they can bring to a company. Most of my discussions focus on the use of towpregs in filament winding, but the benefits I describe can be applied to prepregs as well.

Performance

Several years ago, when I was still selling dry fiber, one of my clients manufactured filament wound composite parts using a competitor’s material — a dry fiber that was wet wound. My customer explained the finished part was too heavy and did not meet performance requirements. I was trying to sell this customer a competitive dry fiber to replace the incumbent material. Based on those discussions, I knew we not only had a chance to earn the business, but also help the customer extract more value from our materials. Because I could speak to the performance advantages of the product I was selling, I could speak authoritatively to the logic of changing materials.

Ultimately the customer adopted our dry fiber over the competitor’s and was able to produce a lighter, smaller part that was paramount in the customer securing a contract worth millions of dollars annually — business enjoyed to this day, all because the performance of our material enabled increased product performance.

However, if I had taken the performance argument a step further, I would have told that customer he had, in towpreg, an even better option at his disposal. Towpreg allows an even greater increase in performance over wet winding, using similar arguments. The same reasons that I used to win that business — reducing mass, size and weight — are reasons why one should consider using towpreg over dry fiber wet winding.

In terms of performance, towpreg allows for translational performance gains of 10-20%. Filament winding companies produce higher performance parts using towpreg by improving translational performance.

Towpreg, for example, protects the fiber bundle more than wet winding. Tows slide over guide rollers but are tacky enough to stay in place on parts, reducing broken filaments and increasing performance. A tighter design tolerance can also be maintained due to the minimum resin variation and increased mechanical properties achieved by use of towpreg. Tighter design tolerances, in turn, lead to reduced composite mass, which leads to reduced fiber and resin use and overall product cost savings. For pressure vessel manufacturers, this translates into faster wind times, lighter and smaller tanks and even a potentially faster cure time due to wall thickness reduction.

The single largest safety benefit of using towpreg is the elimination of the need to mix resins, as required by wet winding.

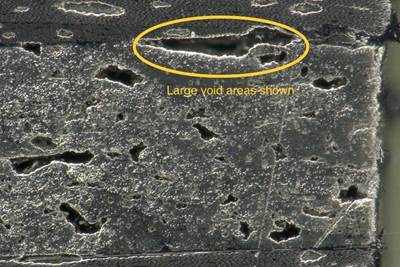

Performance gains for towpreg products are translated through void content, which can be reduced as some towpreg manufacturers use resins free of volatile organic compounds (VOCs), which do not off-gas. Further, towpregs wet out more thoroughly, and because the resin pervades the fiber, void potential and thus crack propagation are minimized.

Other benefits include the ability to store room-temperature towpreg rolls at ambient temperature, and the ability to avoid staging products ahead of time. Moreover, towpregs stored frozen can develop condensation when removed from the freezer. Such condensation can materialize as air bubbles trapped in the laminate.

Safety

Most towpreg suppliers sell materials globally and must be willing to meet safety requirements from the most exacting countries and customers. Like many companies in this industry, my employer, TCR Composites, knows it has a duty to its employees and customers to manufacture products that are of the highest quality and have the lowest risk of use for both parties.

The single largest safety benefit of using towpreg is the elimination of the need to mix resins, as required by wet winding. Wet winding resins contain catalysts that generate chemical reactions, increasing the energy of the system. On-site mixing of these resins can cause an exothermic reaction which, if not dissipated, will begin to smoke and, ultimately, catch fire or explode.

Using towpreg mitigates a large portion of the risk of an exothermic reaction, as no mixing is required. In addition, many resin systems are solvent- and VOC-free, so workers can breathe easily. The risk of fire is also mitigated via trimmed cleaning solvents that are used to clean resin baths, since only a fraction of this chemical cleaner is required to clean towpreg tooling. Many towpreg resin systems have also been certified as non-hazardous compared to other systems. More importantly, many towpreg suppliers are already REACH-compliant.

Other follow-on benefits include potentially reduced insurance premiums (fewer chemicals stored and used) and more focus on production over materials storage, which improves a company’s overall environmental footprint.

The ultimate benefactor of safer materials is the employer. Many of us have seen pictures, or even worked at facilities, where resin systems are so egregiously applied that workers stand in puddles of potentially hazardous chemicals wearing special overalls, boots and gloves. Towpreg eliminates situations like this, which leads to greater employee retention.

A quick Internet search of employee retention costs, show figures ranging from $1,500 for hourly employees to six to nine months of wage for salaried employees. Exact costs are difficult to pin down, but one thing all of the studies point to is that employee turnover is extremely costly.

Increased Profitability

I next want to focus on understanding the value component of towpregs and prepregs, which is often missed when choosing raw materials.

As I have noted, towpreg in particular facilitates faster filament winding speeds, which increases efficiency and reduces operator error. In addition, parts produced with towpreg and prepreg also have better traceability and are produced to tighter tolerances, thereby reducing the coefficient of variation (COV). A lower COV enables higher degrees of confidence during part design which in turn allows a reduced finished part mass.

By incorporating towpreg, fewer operators can now work in a safer environment with greater employee retention. Risk of exotherm, fire and worker injury are reduced significantly. CAPEX is now focused in other areas of the company as machinery utilization is maximized. More parts are produced per shift, with higher quality, using less material, with less labor, in a smaller footprint, using machinery to a higher degree of efficiency. This leads to increased revenues and retention of customers and employees.

About the Author

Brian Bishop

Before joining TCR Composites in 2019, Brian Bishop worked at two of the most advanced composites companies in the world. He has been in the composites business for 20 years, traveling the world marketing and selling materials to some of the world’s largest corporations. He focuses on identification of problems and implementation of solutions to overcome them.

Related Content

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreRead Next

Rediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)