Meeting tolerances measured in microns while churning out more than 4,000 parts per day might seem like a daunting manufacturing challenge. However, at Tier 1 automotive supplier Cloyes Gear and Products’ plant in Subiaco, Arkansas, this is standard procedure for the production of variable valve timing (VVT) stators. The company attributes the consistent, worry-free nature of its stator production in large part to the use of a VSS-2 single-pass honing machine from Sunnen (St. Louis, Missouri). By simplifying the sizing of the stators’ segmented bores, this machine has eliminated a production headache and reduced scrap.

Cloyes’ Subiaco plant houses its powder metal (PM) production facility. Here, the company performs the entire production process for high-strength, low-weight PM parts, including both primary and secondary operations. With presses ranging in size from 60 to 825 tons, the company achieves part densities of 7.5 g/cc in materials including iron; phosphorus iron; pre-alloyed, copper-infiltrated, tungsten-carbide/bronze matrix; and both 300- and 400-series stainless steels; among others. Key capabilities include sintering to 2,250°F; hardening via induction, carburizing and carbonitriding; and a range of secondary operations.

In operation, the VVT stators interface with rotors that move about 15 degrees to adjust valve timing for optimum engine performance, based on rpm and other parameters. They are made of sintered steel with a hardness of 45 HRa. A critical operation in the production of these parts is sizing and finishing the minor ID, which must be performed after induction hardening to achieve the specified 50-micron roundness tolerance and 80-micron total tolerance. The company found this operation challenging, particularly because the minor ID consists of five different segments. “We could turn this ID on a lathe, but it would be very challenging on a production basis because of the highly interrupted bore,” says Justin Carty, process engineering manager at the plant.

The company initially used a roller burnishing process to finish the interrupted bore, but it struggled to meet the required tolerances, resulting in a high scrap rate, Mr. Carty says. Based on its experience with three single-pass honing machines already on the shop floor, the company had built sufficient confidence in that process to choose it as an alternative to roller burnishing. Shortly thereafter, it took delivery of a Sunnen VSS-2 with four spindles and integrated it with an automatic parts loading system.

According to Sunnen, properly applied single-pass honing can provide a quick, cost-effective means of obtaining a precise bore size, geometry and surface finish. The process is especially useful for parts made of cast iron, powder metals, ceramic, glass, graphite or other free-cutting materials. The ideal length-to-diameter ratio is no higher than 1:1, although the process can be appropriate for longer ratios or splined bores if the part contains cross holes or other interruptions that allow chip flushing. (Cloyes’

VVT stators measure 23 mm long and 84 mm in diameter.)

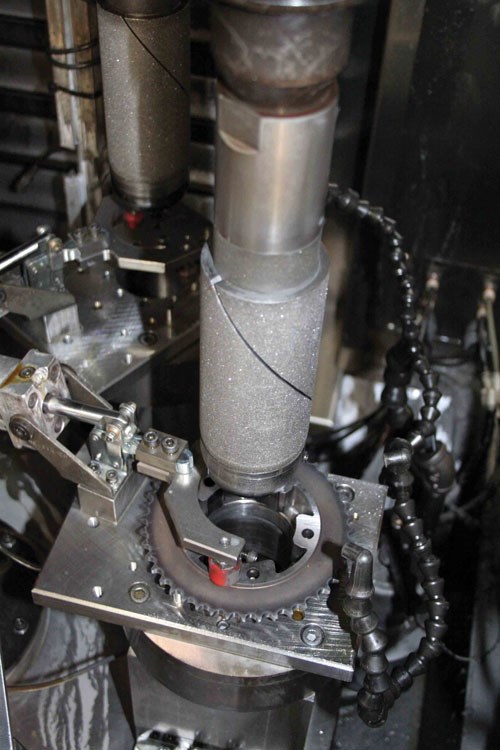

Introduced at IMTS 2008, the VSS-2 series machines are available with as many as six spindles. Using diamond tools with preset diameters and grit sizes, each spindle takes a single pass to progressively size and finish the bore. Spindles are independently aligned at the factory for precision centering with the tool plate. According to the manufacturer, this results in exceptional accuracy that improves bore geometry compared with earlier machines that use an “average” alignment for all spindles. Designed for flexibility and ease of use, the control enables users to vary the column feed and spindle speed throughout the cycle. To further enhance operational flexibility, the machines are available with six different stroke profiles, including pecking, short stroke and dwell.

Cloyes’ VVT stators begin as powdered steel that is pressed, sintered and sized in a restrike press. Then, a small hole is drilled near the part’s periphery. Honing begins after brush deburring and induction hardening the teeth. The bores require re-moving approximately 0.003 inch (0.076 mm) of material, so each of the four spindles takes off a little less than 0.001 inch (0.025 mm). Tool life is around 80,000 parts, Mr. Carty says. After honing, the parts are face ground, deburred, washed and packed.

Like other honing machines on the shop floor, Cloyes’ VSS-2 interfaces with a part-feeding system that includes a Fanuc M-6i robot. This enables the machine to run essentially unattended 22 hours a day. “The system is all about short cycle time, high production rates and high process capability, all without babysitting the machine,” Mr. Carty says. “We might need to make an adjustment once a week to keep the parts within spec. That’s the kind of productivity and process capability needed to be competitive in the OEM automotive market these days.”