Meter/Mix/Dispense Machines: Balancing speed and control for auto CFRP

Suppliers of meter/mix/dispense (MMD) equipment are under pressure to keep pace with process innovations that are drastically reducing mold cycle times for carbon fiber/epoxy laminates in automotive applications.

Suppliers of meter/mix/dispense (MMD) equipment are under pressure to keep pace with process innovations that are drastically reducing mold cycle times for carbon fiber/epoxy laminates in automotive applications. Noting the emphasis on processing speed, JHM Technologies (Fenton, Mich.) president John Moore observes, “They want to force the resin in so fast, they are losing control of the process to keep porosity down.” The objective should be, he says, to maintain control over the process. “Resin producers now have epoxies that cure in four minutes, using heated tooling, putting the goal of SMC cycle times within reach,” he acknowledges. “Yet, it is a whole new animal when carbon fiber is placed dry in the mold and the injection process begins to meet even a 17-minute cycle.”

Moore has experience here, having worked on the original composite parts for Chrysler Group LLC’s (Auburn Hills, Mich.) Dodge Viper. He calls resin transfer molding (RTM) of CFRP parts the next big trend.

To accommodate the trend, JHM Technologies has refined its Infuser SRV EPX system. “It enables study and control of pressure and temperature,” he says, “with infinite hardener ratio control and flow rates of less than 50 grams per minute to multiple liters per minute, all with the same data collection that has been in use on the Infuser PRG for many years.” Moore claims the Infuser SVO EPX offers aerospace-level process control, based on 34 years of molding experience, but at a cost all molders can afford.

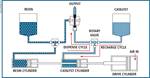

Hennecke (Lawrence, Pa.), a supplier of MMD equipment for polyurethane processing, has developed metering equipment for high-pressure RTM (HP-RTM). Its HP-RTM STREAMLINE machines offer high-pressure mixing and injection of accelerated reaction materials for very short cycle times. Features include modular metering lines, temperature-controlled tanks and pumps with resin delivery via reportedly well-proven “hot air technology” and a self-cleaning mixhead fitted with patented constant-pressure injectors. The latter are said to ensure a controlled injection pressure whether or not the RTM raw material is loaded with fillers. The company is positioning it as enabling technology for manufacturers who want to produce automotive composites using glass and carbon fiber reinforcement.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.